Hitachi-GE Nuclear Energy, Ltd. has put forward a vision for nuclear power that seeks to achieve reduced initial investment risk, reliable power supply over the long term, and lower radioactive waste toxicity. It is currently developing four new reactor designs to realize this vision: the HI-ABWR large light-water reactor, the BWRX-300 highly economical small modular light-water reactor, the RBWR light-water-cooled fast reactor, and the PRISM, which is an innovative, small modular sodium-cooled fast reactor. The HI-ABWR offers a high degree of safety through the rational implementation of equipment as countermeasures to what occurred during the Fukushima accident along with the introduction of new safety mechanisms. The BWRX-300 has been comprehensively simplified to provide both safety and economic performance. The RBWR is a fast reactor based on proven light-water cooling technology, and the PRISM combines a high level of intrinsic safety and economic performance through the adoption of innovative technologies. In the future, the company intends to continue developing technologies to provide solutions to global energy problems and to work towards the early practical implementation of these four reactor designs.

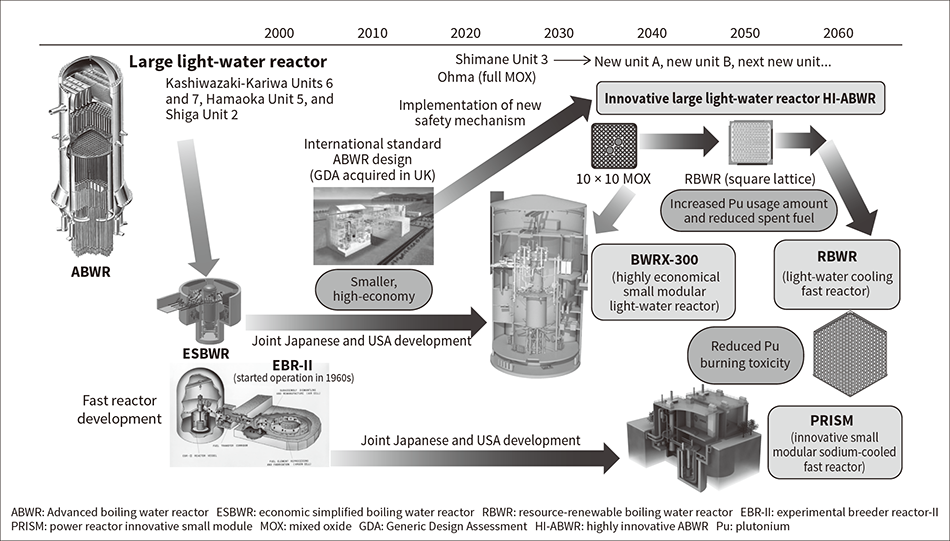

Figure 1 — Hitachi-GE Nuclear Energy’s Nuclear Power Vision Hitachi-GE Nuclear Energy, Ltd. is utilizing open innovation to develop new reactors through joint international development projects based on its BWR construction experience and fuel cycle technology, thereby achieving lower initial investment risk, a long-term stable power supply, and reduced radioactivity.

Hitachi-GE Nuclear Energy, Ltd. is utilizing open innovation to develop new reactors through joint international development projects based on its BWR construction experience and fuel cycle technology, thereby achieving lower initial investment risk, a long-term stable power supply, and reduced radioactivity.

Drawing on its experience with the construction of boiling water reactors (BWR) and fuel cycle technologies, Hitachi-GE Nuclear Energy, Ltd. (Hitachi-GE) is utilizing open innovation for the joint international development of four reactor designs (see Figure 1). These are the highly innovative advanced BWR (HI-ABWR) large light-water reactor, the BWRX-300 highly economical small modular light-water reactor, the resource-renewable BWR (RBWR) light-water-cooled fast reactor, and the power reactor innovative small module (PRISM), which is an innovative, small modular sodium-cooled fast reactor.

This article describes the features of these four reactor designs and the technologies that Hitachi-GE is developing to enable their practical implementation.

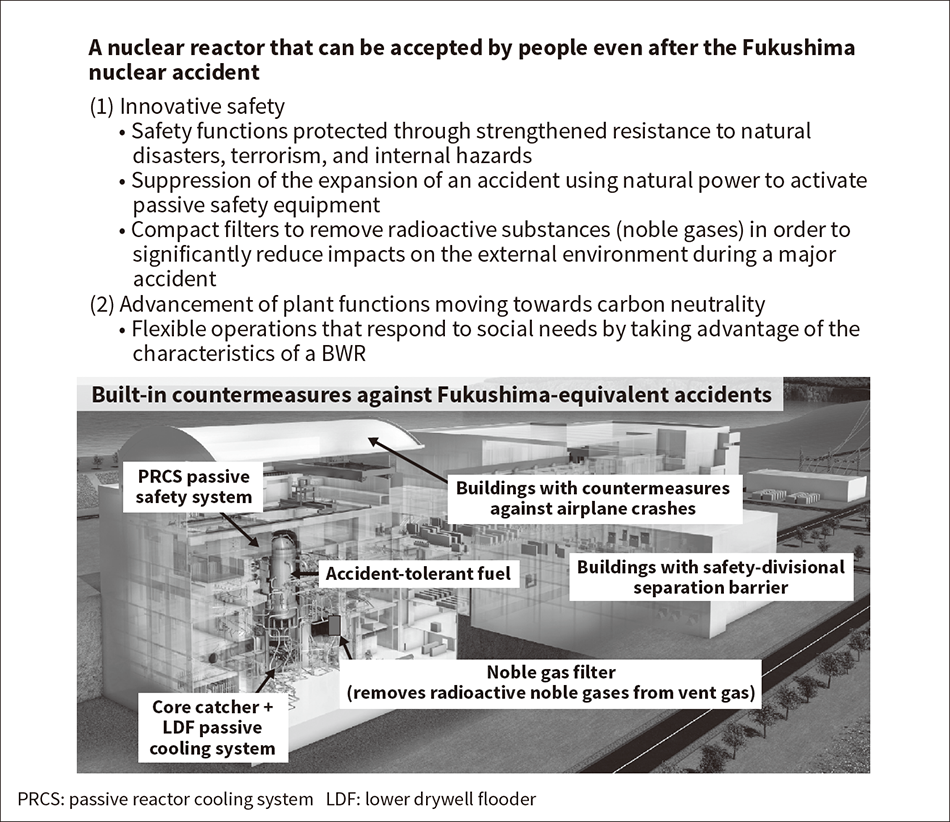

Figure 2 — Overview of HI-ABWR The HI-ABWR is an innovative, large light-water reactor incorporating new safety mechanisms based on the standard international ABWR design, reflecting countermeasures for what occurred during the Fukushima nuclear accident as well as the requirements of UK and European regulations.

The HI-ABWR is an innovative, large light-water reactor incorporating new safety mechanisms based on the standard international ABWR design, reflecting countermeasures for what occurred during the Fukushima nuclear accident as well as the requirements of UK and European regulations.

Various types of safety improvement measures have been implemented on nuclear reactors based on the lessons learned after the Great East Japan Earthquake and Fukushima Daiichi Nuclear Power Station accident (hereinafter, “Fukushima nuclear accident”) of 2011. Hitachi-GE established the international standard ABWR design reflecting the high degree of safety in the regulatory requirements of the UK as well as the lessons of the Fukushima nuclear accident. This reactor, which is called the UK ABWR, incorporates lessons learned after the Fukushima nuclear accident with measures to suppress the occurrence of accidents (such as strengthened resistance to hazards from external incidents, safety-divisional separation barrier inside a building to handle internal incidents, and so on), measures to ameliorate the effects of accidents (prevent core damage, etc.), and measures to handle incidents such as airplane crashes and other terrorist attacks. Following the British certification process, it received Design Acceptance Confirmation (DAC) in 2017.

The HI-ABWR further enhances the UK ABWR’s resistance by implementing equipment designed as countermeasures to the Fukushima nuclear accident for natural disasters, terrorism, and internal hazards from the perspectives of safety and operability during an accident. It reduces the risk of a severe accident, while introducing new improved safety mechanisms in an innovative, large light-water reactor. Figure 2 shows an overview of the HI-ABWR. The plan is to develop and gradually apply improvements by introducing new equipment, including a passive reactor cooling system (PRCS) that can maintain the submergence of the reactor core using natural power to eliminate decay heat after an accident without relying on a power supply or the actions of operators, a noble gas filter that can mitigate the effects of exposure on operators and residents in case a severe accident occurs with an improved radioactive substance containment function, a core catcher that can passively cool molten debris with a debris cooling system if a core meltdown occurs, accident-tolerant fuel with stronger heat resistance that can inhibit the generation of hydrogen during an accident, and others.

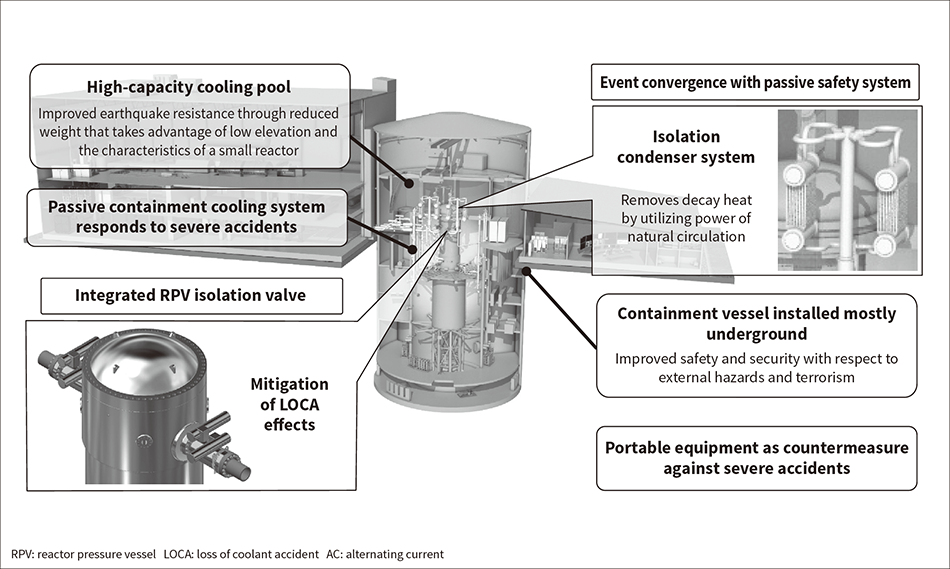

Figure 3 — Overview of BWRX-300 Adoption of an innovative integrated RPV isolation valve ameliorates the effects of a LOCA, and passive safety system configuration allows the safety system to operate even without AC power or operator actions.

Adoption of an innovative integrated RPV isolation valve ameliorates the effects of a LOCA, and passive safety system configuration allows the safety system to operate even without AC power or operator actions.

The value of nuclear power is being re-evaluated as society seeks to achieve carbon neutrality. The deregulated electric power market is looking for power plants with lower power generation costs, smaller capital costs, and reduced investment risks. Against this backdrop, small light-water reactors are drawing the world’s attention. Hitachi-GE is collaborating with its US partner, GE Hitachi Nuclear Energy (GEH) to develop the BWRX-300, which is a small modular reactor based on decades of boiling water reactor experience. The BWRX-300 offers improved economic performance while maintaining a high level of safety.

Figure 3 shows an overview of the BWRX-300. In electrical production configuration, the BWRX-300 produces approximately 300-MWe using a direct steam cycle. The BWRX-300 utilizes isolation valves integrated with the reactor pressure vessel (RPV) to simplify its response to accidents, especially loss of coolant accidents (LOCAs). These integrated isolation valves along with the isolation condenser cooling system (ICS) quickly terminate coolant leaks from piping greater than 25 mm in diameter and form a closed loop cooling cycle with the steam generated in the RPV flowing to the ICS, condensing, and then returning to the RPV. This closed loop cooling cycle is automatically initiated when LOCA conditions are present or there is a loss of power. This enhances the safety of the plant while simplifying the structures, systems, and components. This simplification decreases operating and maintenance costs and decreases the amount of material that must be decommissioned at the end of plant life.

The BWRX-300 utilizes decades of experience and improvements from the BWR and ABWR fleets. Many of the components such as the RPV and reactor internals are the same as, or scaled from, the operating fleets. The fuel used in the BWRX-300 is exactly the same as the fuel used in BWRs in Europe and the USA. The BWRX-300 has 240 fuel bundles, which is the same number as a BWR in Switzerland that successfully operated for over forty years before it ceased operation in 2019.

The BWRX-300 is enjoying commercial success in North America and Europe with prospects in many other countries. The lead BWRX-300 and three follow-on units are being deployed by Ontario Power Generation Inc. (OPG)(1) in Canada. Also in Canada, Saskatchewan Power Corporation(2) has selected the BWRX-300 for deployment in the province of Saskatchewan. The Tennessee Valley Authority electric power company is progressing with its construction permit application for a BWRX-300 at its Clinch River site in Tennessee, USA(3). Orlen Synthos Green Energy is working towards deploying multiple BWRX-300s at several sites in Poland. Fermi Energia has selected the BWRX-300 to construct in Estonia(4).

The BWRX-300 is progressing with licensing in North America and Europe. In Canada, the BWRX-300 has successfully completed a combined Phase 1 and 2 Vendor Design Review(5). The US nuclear regulator has approved five licensing topical reports related to the unique features of the BWRX-300 and two other licensing topical reports are underway. In Poland, the regulator has approved the General Opinion for the BWRX-300 and is evaluating the Decision in Principal for several sites. GEH has applied to enter the first two steps of Generic Design Assessment in the UK.

Hitachi-GE will continue participating in these projects with its US partner GEH.

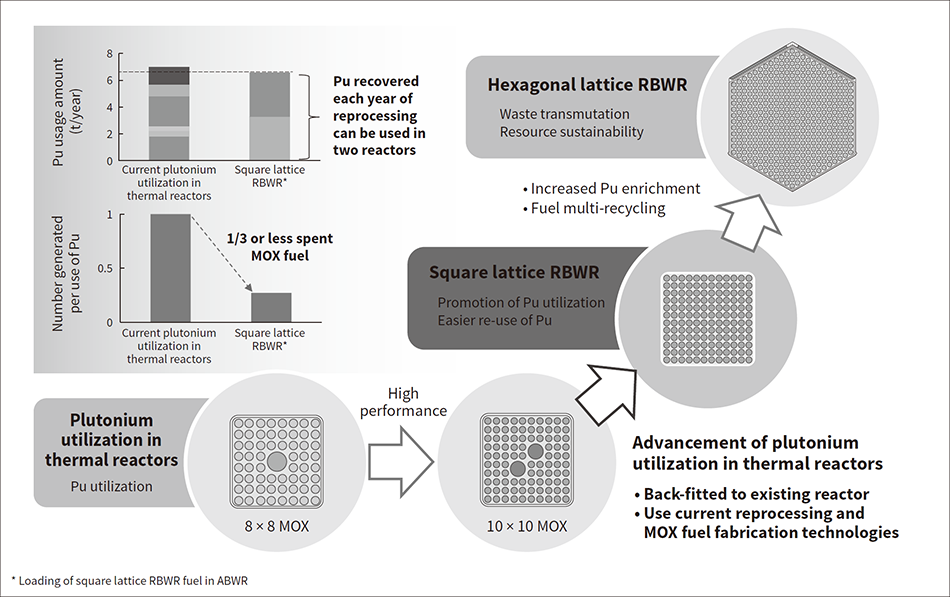

Figure 4 — Envisioned Introduction of RBWR The RBWR uses fuel arranged with rods in a tight lattice in order to suppress the deceleration of neutrons via collision with cooling water and increase energy beyond that of traditional BWRs. Hitachi-GE is promoting the development of a square lattice RBWR that will accelerate the use of plutonium while contributing to a reduction in spent fuel.

The RBWR uses fuel arranged with rods in a tight lattice in order to suppress the deceleration of neutrons via collision with cooling water and increase energy beyond that of traditional BWRs. Hitachi-GE is promoting the development of a square lattice RBWR that will accelerate the use of plutonium while contributing to a reduction in spent fuel.

Hitachi-GE has worked on developing the RBWR, which takes advantage of the characteristics of the BWR by boiling the cooling water (neutron moderator). In addition to this boiling of cooling water, the RBWR uses tight-lattice fuel to decrease the water-to-fuel ratio, and the design shifts the neutron energy distribution to the high-energy side more than in the case of an ordinary light-water reactor. Figure 4 shows the company’s plans for introducing the RBWR. While working towards a final goal of a hexagonal lattice RBWR that achieves a fast reactor cycle, the company is first developing a square lattice RBWR that can be back-fitted to existing reactors to promote the utilization of reprocessing plants, which will facilitate the use of plutonium, and to reduce the volume of spent fuel to maintain the maximum possible utilization of nuclear power generation.

By increasing the plutonium load for each fuel assembly, the square lattice RBWR approximately doubles the plutonium usage amount of the current BWR plutonium utilized in thermal reactors [using mixed oxide (MOX) fuel, which mixes the uranium and plutonium recovered from uranium spent fuels for use in a light-water reactor]. From the perspective of nuclear nonproliferation, Japan’s policy is to only reprocess spent uranium fuels for as much plutonium as it can recover from them for use in thermal reactors, and so, by increasing the amount of plutonium used per fuel assembly, even if the number of plants that can use plutonium is limited, it will still be possible to increase the reprocessing amount and further reduce the spent uranium fuel stockpile. Also, this increase in the plutonium load per fuel assembly decreases the number of spent MOX fuels, using the same amount of plutonium as current BWR plutonium utilization in thermal reactors.

As the decay of 241Pu proceeds during the long-term storage of spent MOX fuel after plutonium utilization in thermal reactors, and since fissile plutonium is insufficient when it is re-used in a fast reactor, there may be cases where additional processing is necessary such as mixing recovered plutonium from spent uranium fuel with a comparatively high ratio of fissile plutonium. Therefore, the square lattice RBWR increases the amount of plutonium used while giving consideration to the re-use of spent MOX fuel generated in square lattice RBWRs in future fast reactors, and uses the fast neutron spectrum with tight lattice fuel to maintain an even higher ratio of fissile plutonium than current plutonium utilization in thermal reactors. The plan is to use this method to reduce the amounts of spent fuel that need to be stored and reprocessed for the transition to the fast reactor cycle.

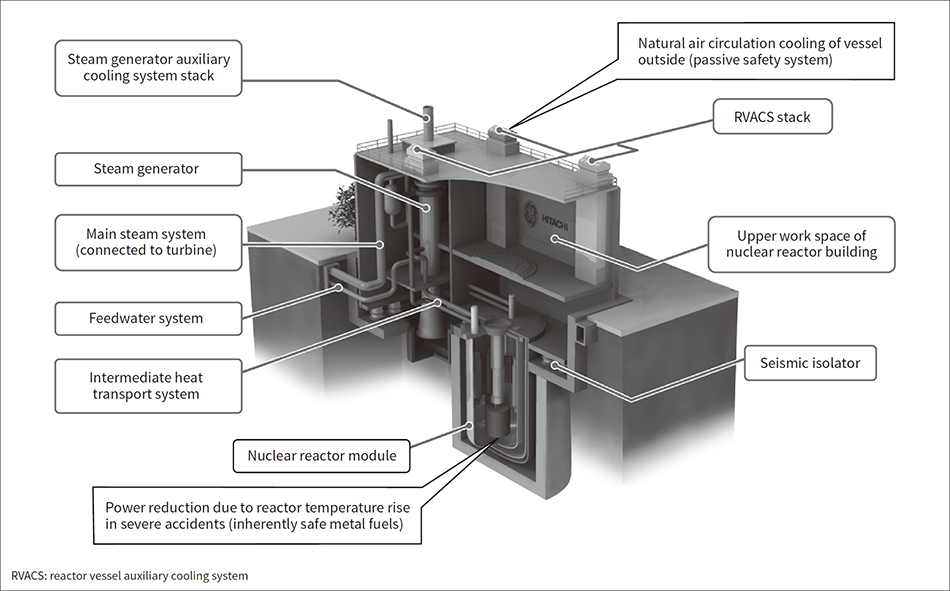

Figure 5 — Nuclear Reactor Module Concept (Provided by GEH) The standard PRISM is comprised of two nuclear reactor modules and one turbine device in a single power block set. This diagram shows the standard nuclear reactor module.

The standard PRISM is comprised of two nuclear reactor modules and one turbine device in a single power block set. This diagram shows the standard nuclear reactor module.

Japan is promoting a nuclear fuel cycle policy utilizing fast reactors to pursue goals such as reducing the amount and toxicity of high-level radioactive waste and maximizing the use of resources. The “Strategic Roadmap” for the development of fast reactors, revised in December 2022, calls for the concept to be finalized by around 2030 and for a demonstration reactor to be in operation by 2050. Hitachi-GE aims to introduce a PRISM-type fast reactor, which is economical, safe, and flexible, in Japan in the 2040s.

The PRISM design was initiated by the General Electric Company (GE) in the 1980s(6) and development continues today by GEH. Figure 5 shows a conceptual diagram of the nuclear reactor module. The PRISM is a fast reactor that uses the reactor vessel auxiliary cooling system (RVACS) as a passive safety system facility to achieve long-term core cooling without power supply and operation during an accident, and metal fuel [uranium-plutonium-zirconium (U-Pu-Zr)] with inherent safety features, etc. And, it has a high density of heavy metals and average neutron energy, making it excellent in terms of economy and effective use of resources. In addition, a flexible plant configuration is possible due to the number of small modular reactors (311 MWe per unit) that can be installed to reduce the initial investment.

For the metal fuel cycle, a concept called the integral fast reactor (IFR) has been developed that integrates the metal fuel fast reactor, pyroprocessing, and fuel fabrication into an integrated facility. Pyroprocessing can simultaneously recover plutonium (Pu) and minor actinides (MA) and re-use them as fuel without removing them from the facility, providing high proliferation resistance and helping to reduce the amount and toxicity of high-level radioactive waste.

Furthermore, the Natrium*, being developed by TerraPower, LLC and GEH and selected for the Advanced Reactor Demonstration Program (ARDP), a program to construct a demonstration reactor in the USA in 2030, uses the PRISM concept for its reactor and a molten salt thermal storage system that stores extra heat according to the demand for electricity. This design option is intended to improve economic efficiency by responding to load variability and renewable energy output variability, and by generating power in response to the electricity market. The PRISM concept will also be demonstrated in this program, and Hitachi-GE, in cooperation with GEH, is considering an early introduce in Japan.

As a feasibility study for domestic introduction, Hitachi-GE will work with GEH and relevant institutions to study the conformity to the regulatory requirements assumed at the time of domestic introduction and introduction scenarios, as well as the safety of RVACS and metal fuel, and will develop a demonstration test plan including the fuel cycle. After the demonstration test, detailed design, and licensing, it aims to introduce a PRISM-type reactor in the 2040s.

This article has described Hitachi-GE’s development of four new reactor designs HI-ABWR, BWRX-300, RBWR, and PRISM, with the goal of lowering the initial investment risk, securing a long-term stable power supply, and reducing radioactive waste toxicity.

Hitachi-GE will continue working to increase social receptiveness through actions such as reflecting nuclear power policies and incorporating user opinions, while using the clean energy of nuclear power to contribute to achieving carbon neutrality and quickly achieving the practical application of these four reactor designs.