July 9, 2014

Development of IE5-class efficiency standard amorphous motor

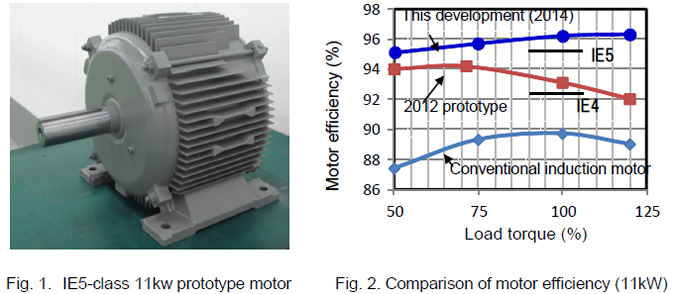

Hitachi, Ltd. and Hitachi Industrial Equipment Systems Co., Ltd., today announced the joint development of an amorphous motor which achieves the highest industrial motor efficiency standard of IE5. This was realized by the development of high accuracy evaluation technology and design optimization of the amorphous metal used in the core of the motor. The new 11kW amorphous motor prototyped with this technology is more compact than the previous 11kW models, and achieved a further 30% reduction in motor loss compared to the IE4-class motor to realize 96% energy efficiency.

A part of this work was supported by The New Energy and Industrial Technology Development Organization (NEDO), Japan, support program for the development of practical technology to substitute or reduce rare metals. In the practical implementation phase, technology was developed to respond to the need for further reduction in power consumption.

Amorphous metals are characterized by their difficulty to process, and large changes in material magnetism caused by the disturbance which occurs when the motor core is machined. In order to raise the efficiency of the motor, it was necessary to devise a means to effectively employ amorphous metals. Using technical know-how built-up through working with amorphous metals in transformers, design optimization was applied to draw-out the desired characteristics of the amorphous metal to greatly increase the efficiency of the motor.