Helps to realize an environmentally friendly society with less product waste by visualizing quality attributes such as freshness and deterioration

May 11, 2021

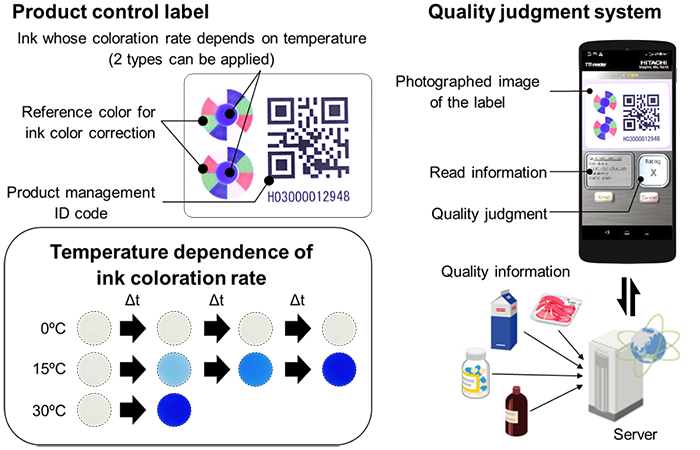

Hitachi has developed an ink whose color develops at different speeds depending on surrounding temperature, which can be used to monitor the quality (freshness, deterioration, etc.) of food and pharmaceuticals. We have also developed a prototype system to create product management labels that combine the ink with an ID code containing product information, and judge the quality of the product based on the degree of ink coloration of the attached label. Using our proprietary digital color calibration technology, we have confirmed that it is possible to scan the ink color density to within a 1% margin of error in different lighting conditions. In the future, Hitachi will work with customers to promote practical uses of this technology. We also aim to apply it to our existing delivery business optimization solution*1 and integrated value chain management platform.*2 In this way, we hope to contribute to the realization of an environmentally friendly society with less product waste.

Quality monitoring system

Introduced on WIPO GREEN, an online platform to promote the use of environmental technologies operated by WIPO*4 https://wipogreen.wipo.int/wipogreen-database/articles/20511

The quality of food and pharmaceutical products deteriorates at a rate that grows exponentially with temperature. We have therefore developed a material whose color development reaction runs slower at low temperatures and faster at high temperatures so that its color is linked to the deterioration of products to which it is applied. Also, by uniformly dispersing this material in ink, we have achieved uniform coloration suitable for image reading.

By printing four color samples around the ink applied to the label and correcting the RGB values*5 extracted from the scanned image, it is possible to digitize the color density of the ink with high accuracy. Color change data acquired in this way can be linked with quality data obtained in advance, so that the quality of a product can be ascertained by scanning an image of the label. By managing this data in the cloud, information can be shared among stakeholders in the distribution process, from production to consumers.

For more information, use the enquiry form below to contact the Research & Development Group, Hitachi, Ltd. Please make sure to include the title of the article.