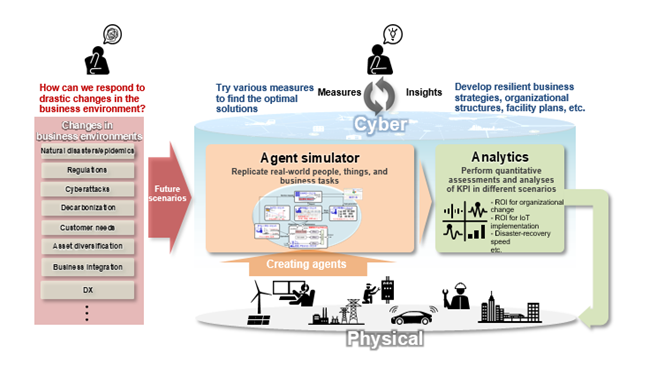

Quantifying the risks and effects of various strategies to help management make timely organizational changes and investment decisions in critical situations

March 29, 2022

Fig 1. Resilience management utilizing agent simulation

Hitachi has developed a simulation technology for facilitating resilience management, which helps companies respond to changes in business environments and harness those transformations for growth. The technology provides quantitative assessments of the risks and effects of various strategies that management might consider in critical situations, thereby facilitating quick decision-making on organizational changes and investment options. To achieve that performance, the technology uses templates for worker models, business (task) models, solution models, and other models as simulation components (agents) and combines them in accordance with the appropriate management scenarios. This approach enables users to validate plans across a broad range of business fields in an intuitive, quantitative manner.

Hitachi looks forward to contributing toward a safer, more secure society by making the technology available to customers that provide social infrastructure services.

Hitachi also plans to present a portion of the technology at the 70th CIRP General Assembly,*1 which was held from August 22, 2021.

The following section explains the newly developed simulation technology in more detail, using the operation and maintenance of a social infrastructure service as an application example.

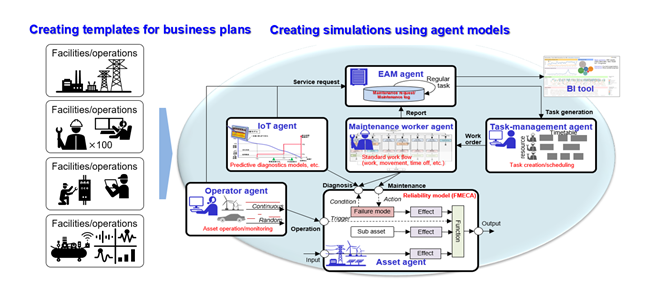

Drawing on pattern classifications and business analyses of various business formats, we created templates of business tasks common to the operations and maintenance of social infrastructure services and used the templates as the components (agents) of the simulation. We also built the models for facilities based on FMECA*2 and other reliability analyses, making it possible to replicate the behavior of facilities with complex structures and attributes. The technology thus allows users to validate plans for a wide variety of tasks, ranging from operations and maintenance for large-scale facilities such as factories and power plants to those for windmills, stores, and other locations that involve on-site work by maintenance professionals. By also incorporating templates for IoT solutions, including state monitoring and failure diagnosis, the technology gives users a valuable resource for evaluating solution implementation plans and target performance.

Simulations with the technology use combinations of the templates (agents) in a state diagram.*3 One of the advantages of this type of agent model is that it lets users replicate a diverse array of business plans by adding or removing agents, such as facilities, workers, and schedulers, to match the size, type, and activities of the corresponding business. The technology also allows users to perform simulations with combinations of agents that reflect actual facilities and organizational frameworks, which enables intuitive, quantitative plan validations without the need for any mathematical modeling or other similar procedures. Another key feature of the technology is that it runs on Repast Simphony,*4 an open-source simulation-development platform, to deliver the benefits of efficient, low-cost implementation.

Fig 2. The technology for creating business-element templates and simulations using agent models

For more information, use the enquiry form below to contact the Research & Development Group, Hitachi, Ltd. Please make sure to include the title of the article.