Contributing to higher reliability and longer service life of power storage systems that use environmentally friendly lithium-ion batteries

December 28, 2022

Hitachi is the first in the world to develop technology to non-destructively diagnose degradation in iron phosphate lithium-ion batteries (“LIBs”) that do not contain rare metals. With a view to more reliable storage systems with longer service life, from fiscal year 2007, Hitachi has been announcing*1 non-destructive diagnostic technology for identifying battery degradation from analysis of data on capacity and battery voltage in ternary LIBs*2 in which rare metals (cobalt and nickel) have been used as the positive electrode. The latest announcement is of development of an analysis technology using capacity and internal resistance data of environmentally friendly iron phosphate LIBs*3 which do not contain rare metals, making it possible to non-destructively diagnose degradation. Hitachi expects this technology to contribute to the realization of a decarbonized society by encouraging uptake of highly efficient, sustainable power storage systems, through wide adoption by providers of power transmission and distribution businesses, and electric-powered mobility solutions.

Some of the results of this research were announced at the 63rd Battery Symposium in Japan held in Fukuoka from November 8 to 10, 2022.

Demand for LIBs is expected to increase as renewable energy for stationary power storage systems and as a motive power source for electric vehicles. Traditionally mainstream ternary LIBs feature high energy density and stable output even at low temperature, but are associated with issues of uneven distribution of mining and refineries for raw materials, environmental contamination, and unstable raw material prices. In recent years, therefore, demand has been growing for iron phosphate LIBs, which do not contain rare metals and are environmentally friendly, and the 2021 global share of 20% is expected to grow to 40% by 2030*4. Technology that enables non-destructive diagnosis of degradation is needed for highly reliable, long service life power storage systems incorporating iron phosphate LIBs. Hitachi has developed non-destructive degradation diagnosis technology for ternary LIBs and has applied it to lengthening LIB service life through degradation forecasting and capacity recovery technology*5. In addition, Hitachi also developed an analysis technology that uses battery capacity and internal resistance data to come up with a method to non-destructively diagnose degradation of iron phosphate LIBs. The features of the technology are as follows.

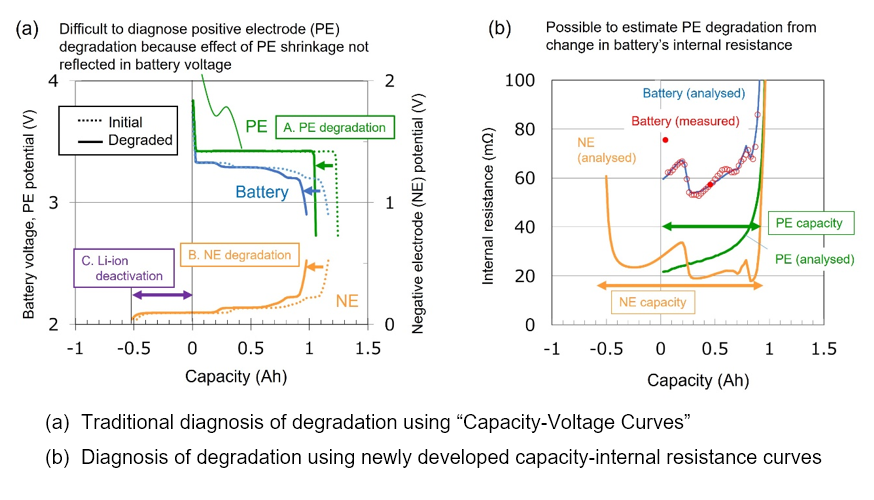

Fig. 1. Technology for non-destructive diagnosis of causes of iron phosphate LIB degradation

Hitachi has developed a non-destructive degradation diagnosis technology (Fig. 1(a)) to analyze the relationship between LIB capacity and voltage (“Capacity-Voltage Curve”) and separate and quantify the causes of degradation: (A) positive electrode (PE) degradation, (B) negative electrode (NE) degradation, and (C) deactivation of lithium ions in electrolytes. In iron phosphate LIBs, however, as shown in Fig. 1(a) the Capacity-Voltage Curve has many flat horizontal sections and the effect of shrinkage in positive electrodes is not readily reflected in battery voltage, which means it is difficult to accurately measure degree of degradation. Hitachi’s attention was drawn to the diffusion coefficient*6 of lithium (Li) ions inside positive and negative electrodes and the changes that occur with capacity. Specifically, by using intermittent discharges in the order of a few tens of seconds to measure the capacity-internal resistance curve and quantify the lithium-ion diffusion coefficient, and then comparing it to data from the separate capacity-internal resistance curves of previously measured positive and negative electrodes, Hitachi has discovered that it is possible to measure degree of degradation for each of the three causes. This technology for analyzing the capacity-internal resistance curve makes it possible to non-destructively diagnose degradation in iron phosphate LIBs with the same precision as for conventional ternary LIBs (Fig. 1(b)). The technology was created in collaboration with specialists in technical fields including battery materials, manufacture, and charge and discharge control, and is also applicable to diagnosis of ternary LIBs.

As the technology becomes widely used by power transmission and electric mobility operators, it will encourage the uptake of highly efficient, sustainable power storage systems and contribute to the realization of a decarbonized society.

For more information, use the enquiry form below to contact the Research & Development Group, Hitachi, Ltd. Please make sure to include the title of the article.