OS&M Green Solutions for Environmental Sustainability

The origins and scope of services comprised within Hitachi Rail’s OS&M Line of Business has resulted in a global organisation with a high level of complexity. This complexity is managed across Hitachi Rail’s regions, through different customers, partners, cultures, regulations and requirements, amongst other factors. The ability to thrive within this environment rests in OS&M’s ability to remain agile. This agility must stem from a standardized baseline of activities and processes, yet be flexible in regional approach. It is through the constellation of asset management and the investment in technology that OS&M activities will be set apart from the competition. This article describes initiatives undertaken by Hitachi Rail’s OS&M Line in consideration of sustainability and green solutions.

The operations, service & maintenance (OS&M) landscape is complex. OS&M acts in a multi-dimensional space to optimise cost, delivery time, and quality, as a result of continuing efforts to harmonise available technologies, resource capability and global processes.

OS&M is a unique line of business (LoB) and offers a complete spectrum of services. These services range from traditional service and maintenance (S&M) of a train, through to full operation and service (O&S) of stations, ticketing and provision of signalling equipment. These services must be delivered across a range of operating models, within different regional cultures, regulations, and laws. Consideration of the Riyadh metro highlights the complexity of this landscape. The Riyadh metro is the world’s largest metro, at 176 km in length, operating across 85 stations. Hitachi Rail Limited is the leader of the FLOW consortium* who manage the operation and maintenance (O&M) contract for 50 stations of four out of the six metro lines and 3 depots. The employees within this consortium reach at least 3,500, and work across three different transit systems products. Logistically, Hitachi is responsible for one of the most complex OS&M contracts in the railway industry, coupled with the resourcing, stakeholder and mobilisation challenges associated with an organisation the size of the FLOW consortium.

Management of a global function intimates a level of de-centralised leadership whereby regions operate under their own regional heads, but are accountable to management located outside of their day-to-day contact. Whilst essential, de-centralised leadership necessitates oversight reporting and constant visibility of performance, successes, and risks in all regions. The ongoing development of OS&M key performance indicator (KPI) oversight reporting system and dashboard creation is essential for transparent management of the OS&M regions.

OS&M, as a global LoB, is new, with no legacy acting as a foundational platform from which it may grow. It is learning from its experiences as it matures. Operating across a maturing organisation must strike a careful balance between excelling at the services, whilst testing new markets, products and technologies. Continual assessment of the capabilities within the LoB are essential to maintain its current baseline of activities while enticing the best of new talent in digital mechatronics to pave the way for Hitachi’s future.

Maintaining products across geographical regions sees the challenge of consolidation and review of the extensive range of systems and digital solutions available, following the amalgamation of businesses that formed the OS&M LoB including marketing departments and sales ones. The answer to this is the constellation of advanced asset management and alignment of Hitachi systems. Digital solutions and systems must be brought together to develop integrated system solutions that can be used by any OS&M employee across the globe. This includes the acquisition of further suitable digital providers, such as the newly acquired Perpetuum Ltd. which will strengthen OS&M’s digital offering through the ability to undertake needs-based maintenance planning, and forecast modelling to accurately understand when maintenance will be required, through the use of technology. It is through the use of data and digital technologies that OS&M will be able to explore new customer segments, and be a pioneer for new products and services(1).

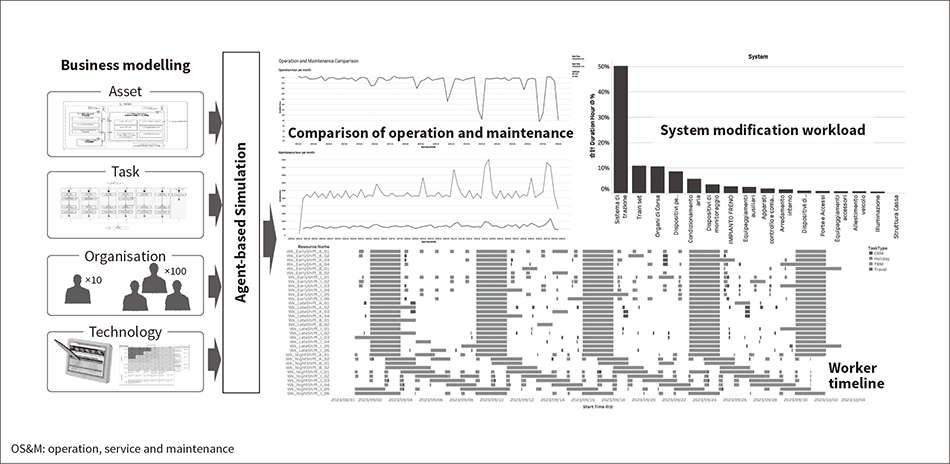

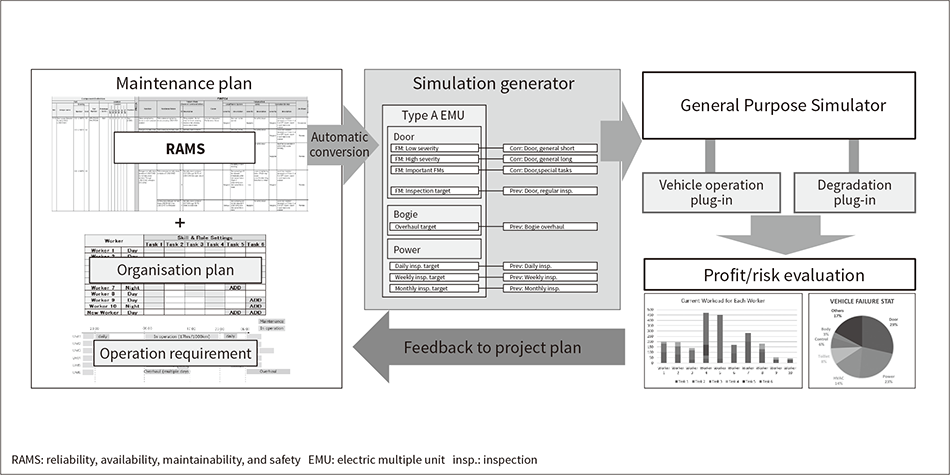

Hitachi plans to consolidate OS&M businesses in the well-established UK and Italian markets, and to expand in the USA and Middle East. This will require standardisation of global activity, yet flexibility in regional approach. OS&M are undergoing the introduction of a flexible, simulation-based solution, OS&M simulator (see Figure 1). This solution will allow Hitachi to respond quickly to both customers and the global market, through the prediction of relevant KPIs as well as. It will allow for analysis of business processes, activities, and projects, to understand where improvements should be made. It has been developed in collaboration with the Center for Technology Innovation – Controls, Research & Development Group, Hitachi, Ltd. (see Figure 2).

The simulator models maintenance according to the standardised maintenance modelling framework, based on standard reliability analysis methods, such as failure mode, effects, and criticality analysis (FMECA) or reliability centered maintenance (RCM), and innovative methods such as predictive maintenance and condition based maintenance (CBM). The simulator manages a huge amount of input data and information is refined during the product design process. This allows a focus on the sensitivity of the business’ KPIs on specific parameters, so as to facilitate the adjustment of maintenance to optimum levels. This is a powerful tool for supporting Hitachi’s tendering and contract-based decisions.

Figure 1 — Overview of OS&M Simulator The figure shows the required inputs and outputs obtained from simulation-based solutions.

The figure shows the required inputs and outputs obtained from simulation-based solutions.

Figure 2 — Architecture of OS&M Simulator The OS&M simulator periodically feeds back an evaluation based on the simulation data in a comprehensive approach.

The OS&M simulator periodically feeds back an evaluation based on the simulation data in a comprehensive approach.

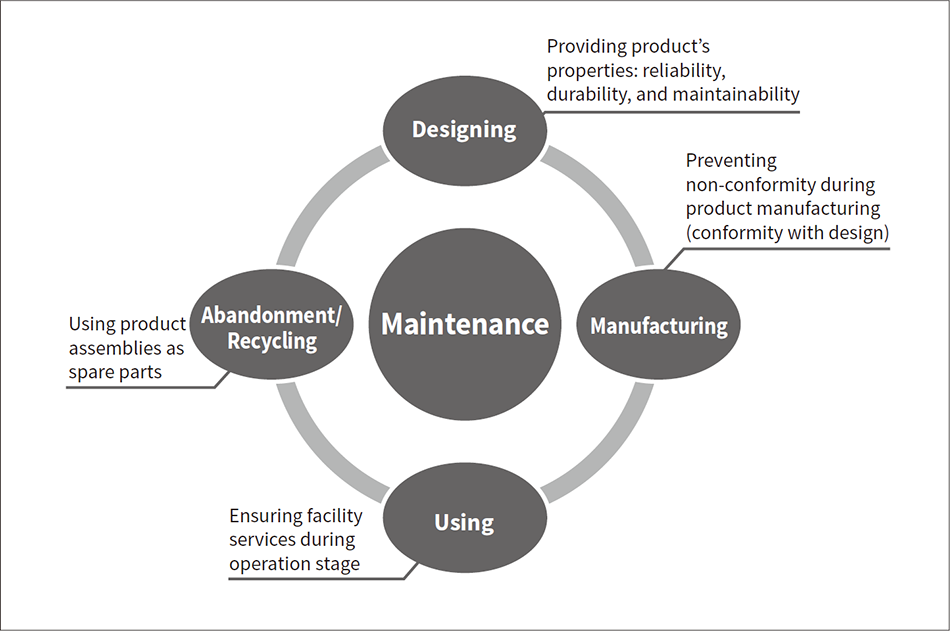

Figure 3 — Maintenance Role in Environmental Impact The figure shows the role of maintenance throughout the design, manufacturing, use, and disposal/recycling processes in terms of the environmental impact.

The figure shows the role of maintenance throughout the design, manufacturing, use, and disposal/recycling processes in terms of the environmental impact.

Improvement of efficiency and the way of conducting OS&M business enables reduction of the product life cycle cost (LCC) and environmental impact caused by Hitachi’s business activities. Hitachi Rail products and systems are maintained based on a complex maintenance strategy. The overall system must be evaluated before deciding on the implementation of a new maintenance plan.

Hitachi Rail looks to harness the digital technologies available throughout the Hitachi Group, such as Perpetuum to improve maintenance. The huge potential for artificial intelligence (AI) and the Internet of Things (IoT) to provide value in maintenance is acknowledged by many companies. However, there is a lack of sufficient knowledge surrounding these techniques within the industry and the role they will play when developing solutions considering both the environmental and economy.

OS&M is working to fill this gap in Hitachi Rail’s business by using a sustainability for maintenance approach that combines the life cycle assessment (LCA) methodology and LCC methodologies (see Figure 3).

KPIs are identified to define the environmental footprint of Hitachi Rail’s maintenance(2) focusing on resources (water, energy, materials), efficiency (energy consumption, contaminant discharge), and waste management (by-products, used parts). In turn, these KPIs may be influenced by other factors:

Green solutions for environmental sustainability are varied; there is no “one size fits all” model, particularly within the complex landscape of OS&M. Hitachi solutions range from management of its people, executive-level sponsorship in green initiatives, sustainability training, a comprehensive maintenance management system, efficient spare parts management and maximising the performance of its assets.

It is clear that OS&M, as a global LoB faces many challenges, of which sustainability will only continue to grow in importance. It is OS&M’s ability to remain agile, manage complexity and embrace modern technologies, whilst operating to its continually high standard, which will forge the path for the expansion and growth of operations and maintenance activities into the future.