COVER STORY:TRENDS

Establishing Innovation Ecosystems and Strengthening Measurement Technologies that Underpin Industry

Kazuhiko Ishimura

Kazuhiko Ishimura

President & CEO

The National Institute of Advanced Industrial Science and Technology

After joining Asahi Glass Co., Ltd. in 1979, he was appointed Senior Manager of the Engineering Division in 1989; President of Asahi Glass Fine Techno Co., Ltd. in 2000; General Manager of Asahi Glass (Kansai Plant) in 2004; Executive Officer in 2006; Executive Officer and General Manager of the Electronics & Energy General Division in 2006; Senior Executive Officer in 2007; Member of the Board, President, and COO in 2008; Member of the Board, President, and CEO in 2010; Chairman & Representative Director in 2015; Chairman and Director in 2018; and Chairman and Director of AGC Inc. in 2018. He was appointed to his current position in 2020.

He is a director of TDK Corporation, IHI Corporation, and Nomura Holdings, Inc. He also served as Chairman of the Japan Soda Industry Association (JSIT) and Chairman of the Asahi Glass Foundation. In 2018, he was made a Commander of the Order of the Crown by the Kingdom of Belgium.

Societies today face challenges that are getting larger and more complex, among them climate change and the efforts to counter it by achieving carbon neutrality, aging populations with declining birthrates, and the sort of unpredictable changes exemplified by pandemics caused by new infectious diseases. With industry expected to play an active part in addressing these social problems, doing so will require both innovation and a change in mindset. With SDGs now a universal keyword, and as the trend towards digital transformation accelerates, how should companies be going about new business development and R&D? What is needed to create innovations that contribute to solving problems, and to develop measurement technologies as a foundation for industry? And what role should the National Institute of Advanced Industrial Science and Technology play in all of this? Kazuhiko Ishimura has led the institute as its President since April 2020. Here are his views on these questions.

One of the terms used to describe modern society is “VUCA,” an abbreviation of “volatility,” “uncertainty,” “complexity,” and “ambiguity.” The problems we face today are becoming increasingly complex and layered on a global scale, with VUCA being a factor in most of them. Examples include the problem of climate change, which is a complex interplay of factors and interests, and the recent COVID-19 pandemic that has been accompanied by a steady stream of unexpected outcomes. These are clearly not problems that can be solved by one company or one country alone.

This situation is also forcing changes in how business is done. Activities such as addressing environmental problems were in the past treated as a cost to business, being part of corporate social responsibility (CSR) and separate from customer demands for quality, cost, and delivery (QCD). Now, however, “environment, social, and governance” (ESG) issues have become an important factor in investment decisions and the United Nations Sustainable Development Goals (SDGs) are taking their place alongside QCD as a fourth form of value.

With demands now encompassing human rights, ethics, and diversity as well as the environment, a change in mindset is needed that sees these not as a negative cost, but as a means of differentiation that will enhance profitability, something that increases corporate value and provides business opportunities. This is, then, an era in which the companies that thrive will be those that can incorporate SDGs into their management strategies and connect their business activities to solving social problems.

Among the problems facing modern society, carbon neutrality is one for which corporate leadership will be particularly vital. Japan has set an ambitious target of carbon neutrality by 2050, and this can be seen as a business opportunity for industry. The author, however, personally believes it would be wrong to follow such extreme courses as shutting down all thermal power generation. How each country goes about solving these problems should be tailored to its own respective circumstances, and there should be more than one path to innovation. There is no point in achieving carbon neutrality if it is at the cost of Japan’s prosperity.

Meanwhile, moves toward using technologies such as the Internet of Things (IoT) and artificial intelligence (AI) for digital transformation (DX) are accelerating change in the business environment. Digital technologies by their nature are able to overcome the constraints of time, space, and scale. In manufacturing, for example, linking data together across all processes from research and development (R&D) to design, production, and distribution can significantly shorten the time required for product development and commercialization, and provide the flexibility for making changes to designs and specifications, etc. In addition to using simulations in virtual space to speed up development, there is also scope for creating industrial cyber-physical systems (CPSs), with capabilities that include cooperative control linking remotely located factories and other production facilities, and productivity improvements achieved by coordinating the activities of people and machines.

For companies, however, DX is becoming less of a means of differentiation, and more of a prerequisite for survival. For both countries and companies, failure to embrace digitalization will only result in being left behind. DX in itself is not a growth strategy. Rather, the question to be addressed is how DX can be utilized within a growth strategy.

In terms of the mindset and talent required, this era of DX, in which many different elements are linked together to create value, calls for personnel who can design entire products, services, or whole business models, both with a view to their future development as well as their cross-deployment into other fields. It also requires personnel who are capable of not only problem solving, but also “task setting.” While the cultivation of personnel with digital skills is recognized as an urgent need, putting data to use requires domain knowledge of the relevant environments, products, and technologies, hence, familiarity with digital technologies is not enough on its own. Therein lies the difficulty, though conversely, the very fact that familiarity with digital technology alone does not suffice could be perceived as an asset from a diversity standpoint.

At its Innovation School*1 and Design School*2, the National Institute of Advanced Industrial Science and Technology (AIST) aims to foster personnel who can contribute to the strengthening of technology management capabilities. The two schools operate curricula that seek to enhance students’ task setting skills, as well as their abilities to engage in collaboration with researchers from other disciplines to create and promote projects. While skills like these have always been a universal necessity, the ability to take in the overall situation and produce comprehensive designs is becoming more important than ever in the face of rapidly increasing uncertainty in society.

In order to turn crisis into opportunity, both companies and the individuals who work for them must have “dynamic capabilities,” meaning the ability to adapt themselves to changing circumstances. Of particular importance to fostering such skills and adapting to change is diversity. While individuals enhance their skills in their particular areas of specialty, new ideas emerge when people with different backgrounds engage with one another to bring together a variety of knowledge and views, enabling a flexible response to changing circumstances. Although Neanderthals, with their greater physical stature and brain volume, were thought to be superior to Homo Sapiens as individuals, one theory for why Neanderthals lost out in the struggle for survival was that they did not interact with other groups and lacked diversity.

It goes without saying that diversity is also a prerequisite for innovation. Its importance has only grown in recent times. Achieving carbon neutrality, for example, although essential for creating a sustainable society, is also very challenging and will require entirely new technological breakthroughs. The conventional division of specialties and in-house approach to technology development are entirely irrelevant. Along with closed innovation involving people with specialist knowledge from different fields working together within a particular organization, open innovation with others from outside the organization has also risen in importance over recent years.

One of the factors behind the prolonged slump in Japan’s economy during the so-called, “lost 30 years,” was that the homogeneity and pressure to conform found in Japanese companies became impediments to growth. Upskilling in an effort to catch up with Europe and America was the driving force behind growth in post-war Japan. In such an environment where the objective was so clearly laid out, homogeneity was seen as a strength. Once Japan had caught up, however, it needed to choose its own future objectives and challenges, and to produce innovative technologies and establish industries with a strong growth potential. Instead, only the homogeneity and in-house mentality remained without new objectives being set, and ecosystems that would foster innovation could not be established.

Getting past Japan’s economic stagnation will require a shift away from this in-house mindset. In the carbon neutrality example raised earlier, a variety of technological breakthroughs are needed. This is difficult for any one company to achieve alone. What is needed, rather, is to pursue development through open innovation, in which a number of companies and research institutions bring their respective strengths to bear.

The idea of open innovation spanning different industries, fields, and organizations was proposed by Professor Henry Chesbrough of Harvard University in 2003, and its importance has since been advocated also by the Japanese government and economic organizations. That many companies nevertheless remain wedded to an in-house approach is apparent based on the low level of research funding invested by Japanese corporations in universities and public research institutions. According to data for 2018, of the 14 trillion yen spent on R&D by Japanese companies, only around 100 billion yen (0.7% of the total) was invested in funding for joint research with universities and national research institutions. This is very low compared to countries like the USA, Germany, and China. That much of this joint research is in fact no more than mere outsourced research reinforces how pressing the need is to accelerate open innovation.

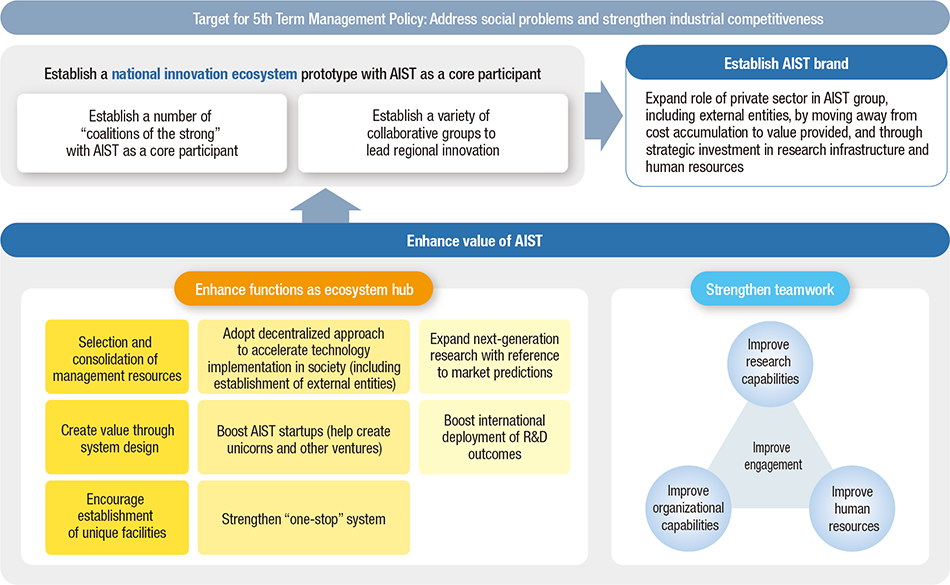

With these circumstances in mind, the author feels that now is the time to reconsider what role AIST should play. AIST commenced its Fifth Medium- to Long-term Plan in FY2020, with a mission of “addressing social problems and strengthening industrial competitiveness.” To put this plan into action and help Japanese companies and the Japanese economy regain their shine, AIST’s 5th Term Management Policy presents a vision for the future beyond FY2030, in which it will become “a core participant of an innovation ecosystem for Japan” (see Figure 1).

Working in partnership with universities, public institutions, and companies with strengths in different areas, AIST will play a central role in facilitating the rapid and seamless social implementation of technology seeds that emerge out of basic research. Repeating a cycle in which the benefits arising from this process are put back into it, then linked to the creation of new technology seeds, will result in the birth of new innovations. AIST will work to establish such an ecosystem in Japan.

As the institute works toward realizing this vision, its immediate objective is to establish a prototype of this ecosystem by FY2024. This will involve a number of “coalitions of the strong” with AIST playing a core role, and the establishment of a variety of collaborative groups to lead regional innovation. The intention is that these coalitions of the strong will bring together companies, universities, public institutions and other organizations that, regardless of size, have strengths that clearly differentiate them from others, and combining these strengths and leveraging synergies for the development and rapid social implementation of technologies that can contribute to addressing social problems. Specific examples include the joint research AIST is conducting with Toyota Motor Corporation and Toyota Central R&D Labs., Inc. on clean energy, a key to achieving carbon neutrality, and with Sompo Holdings, Inc. on efficient and high-quality nursing care systems and business. As for collaborative groups that lead regional innovation, the aim is for 11 research bases located throughout Japan to function as hubs for regional development that can contribute to solving the problems their communities face. One example is the work that AIST Chugoku in Hiroshima Prefecture is doing with a group of companies from the automotive sector on strengthening the foundations of the manufacturing industry. Another is a healthcare industry development through collaboration between AIST Shikoku in Kagawa Prefecture and the medical schools of nearby universities. The plan is to further increase the number of groups following this regional innovation model.

A general feature of Japanese industry as a whole is that it has a large number of companies with strength in the technologies of materials and production. These are technologies that are difficult to imitate, being dependent on the accumulation of workplace knowledge, tacit skills, and empirical know-how. Many of those technologies, which include ultra-pure or high-function materials and microfabrication, provide a strong competitive advantage. However, the companies that possess expertise in these technologies are vulnerable to fierce pursuit by overseas competitors. To maintain competitiveness, it is important that they differentiate themselves in ways that are not easy to copy; these include integrating technologies from a variety of other fields including IT. The author believes that the emergence of many Japanese companies that continue to lead the way through their superior technology will help overcome the nation’s stagnation.

Figure 1 | National Innovation Ecosystem with AIST at Its Core

Enhancing the value of AIST is a major theme in its 5th Term Management Policy (see Figure 2). As a first step in achieving this, and with the aim of strengthening its core function of conducting research, AIST has, since the previous fiscal year, been engaging in research that combines the strengths of its seven research departments: energy and environment, life science and biotechnology, information technology and human factors, materials and chemistry, electronics and manufacturing, geological survey, and metrology and measurement standards. With funding from the presidential discretionary budget, AIST promotes academic research of a sort that it is particularly well-placed to perform, including interdepartmental projects, cross-disciplinary research for young researchers, and interdisciplinary research for solving problems.

The interdepartmental projects, for example, set out to address four specific social problems, namely, responding to energy and environmental limitations, measures for tackling a declining birthrate and an aging population, contributing to strong national lands and prevention of disasters, and responding to COVID-19. Work on energy and the environment has included establishing the Global Zero Emission Research Center (GZR), and partnering with the Fukushima Renewable Energy Institute AIST (FREA) to conduct energy decarbonization research. Laboratories set up to address resource recycling and harmony with the environment are working in such areas as conversion of the waste and other materials into useful resources, and the development of practices for the measurement, assessment, and remediation of environmental impacts.

To address a declining birthrate and an aging population, the Industrial Cyber-Physical Systems Research Center is combining technologies such as sensors, robots, and AI capable of working in harmony with humans to develop ways to improve labor productivity and facilitate skills transfer. Laboratories studying next-generation therapeutic and diagnostic techniques and next-generation healthcare services are developing technologies to extend healthy lifespans. To strengthen national lands, the Sustainable Infrastructure Research Laboratory is developing innovative techniques for assessing infrastructure health and extending its longevity. Efforts to respond to COVID-19, meanwhile, include infection risk assessment at large events and destinations that attract large numbers of people.

AIST has also been strengthening its network of international research collaboration, having entered into 25 comprehensive and 43 specific memoranda of understanding with leading research institutions from around the world as of December 2021. In doing so, it aims to leverage its global research network to help address global as well as domestic challenges.

Defining AIST’s value through initiatives such as these will, the author believes, help to solve social problems and strengthen Japan’s industrial competitiveness. Hitachi has, since its inception, pursued a mission of contributing to society through superior, original technology and products, and is now pushing ahead with its Social Innovation Business. The author looks forward to companies like Hitachi that possess such a philosophy and competitiveness, joining AIST as partners in its coalition of the strong to establish a national innovation ecosystem.

Figure 2 | AIST 5th Term Management Policy Aimed at Solving Social Problems and Greater Industrial Competitiveness

Measurement and sensing technology is among the technologies that will be of growing importance in times to come. In a data-driven society, the means of generating said data are essential. Furthermore, as the saying goes, “you can’t make what you can’t measure,” and the development of measurement techniques is more than just the wellspring of manufacturing; it is the foundation of all industries. For example, electronic devices can now be mass-produced because Hitachi High-Tech Corporation applied electron microscopes to the task of measuring the dimensions of semiconductor circuit patterns, thus enabling precise production control. It should not be uncommon for advances in measurement technology to open up new possibilities, whether it be in R&D or in business, such as enabling more detailed analysis of existing phenomena, or providing a view of what was previously invisible.

One memory of the author’s time at Asahi Glass (what is now AGC Inc.) is how much he struggled with measurement in his work on the production of glass for liquid crystal displays (LCDs). At that time, Asahi Glass developed the technology for LCD glass production in-house. The requirements were for glass of 0.5 to 0.7 mm in thickness, with uniform thickness across the entire sheet that had to be polished to a tolerance of around 5 to 10 µm during the finishing process. While this polishing needed to be measured to an accuracy of 1 µm, the sheets were 300 to 400 mm in size, which meant that a micrometer could only be used at the edges, and contact with the glass during measurement was also a problem. With no other choice, the weight was measured before and after polishing to estimate the mean quantity of material removed, but this still provided no indication of thickness variability. Moreover, ultrasonic thickness gauges were of no use because of their poor accuracy.

Ultimately, what made the volume production of LCD glass possible was that, after much trial and error, it became possible to achieve thickness measurement accuracy of around 0.1 µm by using a laser beam and measuring the difference in optical path distance of the reflections from the upper and lower surfaces. It was an opportunity to learn the hard way, just how important measurement is to advances in technology.

In the past, not only measurement, but also the collation and processing of measurement data has taken considerable effort. As this information can now be obtained as digital data and processed by AI, there may now be many fields where progress would accelerate if only measurement were possible. The ability to perform measurements also advances standardization. Only those who possess the technology for measurement can pursue strategic standardization.

In industry, for example, technologies are being developed to boost productivity by using data to visualize, analyze, and utilize things like the movement of goods in upstream and downstream logistics, or the movement of people and things inside factories. There is also potential for collecting and utilizing data on the condition of social infrastructure and how it is used, or about the atmosphere, rivers, forests, etc., so that it can be applied to things like infrastructure maintenance, environmental protection, and disaster prevention.

In addition to measurement, technologies that add value by assigning meaning to the data collected, or that provide accurate and well-balanced feedback are also important. AIST is conducting research on technologies necessary for treating data collection by human measurement, prediction and analysis by AI, and its feedback to people as a single, integrated entity.

Strengthening the technical foundations of measurement is also important. Consistent accuracy is among the most important factors in measurement. The ability for anyone, anywhere, at any time to be confident about relying on measurement results is the cornerstone not only of industry, but also of people’s overall way of life. AIST’s National Metrology Institute of Japan (NMIJ) supports this ability in its role as a national metrology institute (NMI).

To certify the accuracy of measurement results, instruments have to correctly adhere to national and international standards, and the results have to be comparable (calibratable); in other words, measurement traceability is essential. This traceability is substantiated by “calibration certificates” which certify that the calibration service provider correctly inspected the instrument. However, because these certificates are issued as paper documents, it takes a lot of effort to verify the reliability of measurement results across multiple companies. AIST is developing a technology that will allow the reliability of instruments to be verified simply by connecting to a network, making it possible to share the certificates in digital form. AIST is also working on making compliance management borderless and international through its participation in international standardization study on digitalizing the mechanism for mutual international recognition of calibration certificates between companies in different countries.

Meanwhile, AIST’s research that looks to the future of measurement and sensing goes further. One example from the environmental field is technology for accurately measuring the supply of hydrogen, a fuel seen as a next-generation energy source, and the standardization of said technology. For storage batteries crucial to achieving carbon neutrality, AIST is further enhancing its technologies for the precise measurement of electrical properties, and developing techniques for assessing battery degradation.

In the field of infrastructure maintenance, AIST is developing a technique that combines drones, robots, and AI-based data analysis to measure the deformation of structures, such as curvature in bridges or other elevated locations, with a resolution of 1 mm or less.

The COVID-19 pandemic is a major issue of the moment, and in terms of measurement techniques, AIST’s response has included rapid development and rollout of precision planar blackbodies needed for calibrating the sensors of infrared body surface thermometers used to measure body temperature in a non-contact manner. To improve the reliability of polymerase chain reaction (PCR) testing, an experimental program for PCR testing skills using certified reference material (nucleic acid) supplied by AIST was developed, contributing to the skills assessment of testing staff.

Of equal importance as technology development is the training of personnel who are able to understand measurement. Product development requires being able to grasp, and quantitively measure, quality and performance requirements as specific physical quantities. In other words, what is needed first and foremost is the ability to identify which factors matter and to know what needs to be measured. These same skills are also essential for DX service design that is predicated on the use of data. If these measurement skills are lacking, one should consider developing them for oneself, and one needs to be able to judge the quality and reliability of the measurement results.

Whether it be in product development or service development, the data-driven society will call for people capable of design thinking that encompasses everything from measurement to materials, manufacturing and inspection practices, the differentiation of products, and business models.

If we consider that measurement can lead to the creation of new ideas and things, it is fair to say that measurement is an essential ingredient in innovation. AIST is putting a lot of effort not only into the development of measurement technology, but also into the training of people with skills in this field, the aim being to work with both companies and the public to contribute to innovation while also strengthening Japan’s industrial competitiveness.