In order to continue to provide a safe, secure, and sustainable sewer infrastructure, a variety of issues need to be addressed, including increasingly heavy rainfall, preservation of water quality in public waters, realizing abundant oceans, response to climate change (decarbonization and energy conservation), and the shrinking number of skilled operators and labor saving. Hitachi aims to solve these issues using various approaches, including hardware (such as equipment installation), software (such as data utilization, modeling, and AI), and sensing for connecting software and hardware. This article describes the current status and future prospects of these technologies that will revolutionize Hitachi’s sewage treatment solutions.

Amid a growing number of challenges, including increasingly heavy rainfall, preservation of water quality in public waters, a shrinking number of skilled operators, aging facilities, declining population and income, and actions to prevent climate change and to achieve decarbonization, the mission of sewage systems to contribute to building a society capable of sustainable development, as stated in the “New Sewerage Vision” prepared by the Ministry of Land, Infrastructure, Transport and Tourism in 2014, is becoming increasingly important.

The acceleration strategy to achieve this is continuously reviewed, with climate change, water environment management, and decarbonization as key challenges that were particularly emphasized in the 2022 review(1). The heavy rains that are becoming the norm due to climate change will not only increase the risk of inland flooding, but also increase environmental risks if stormwater is discharged without adequate treatment. Also, the challenges of water bodies, such as nutrient deficiencies and red tides, vary depending on the region and season. Appropriate water environment management according to actual conditions, such as sewage treatment control, is required to achieve clean and abundant oceans. Furthermore, sewage treatment plants, which account for 0.7% of Japan’s electricity usage, are expected to play a role by converting sludge into a renewable energy source in addition to decarbonization through energy conservation, and the effective operation of water treatment and sludge treatment is also important. In this situation, the above-mentioned acceleration strategy cited sewage digital transformation (DX) as one method of attaining these objectives.

The Hitachi Group, which supports the operation of sewerage systems that are required to play an increasingly key role, is working to overcome these challenges from various perspectives based on digital technology, including the linkage of software and hardware, artificial intelligence (AI), and sensing. This article describes these innovative state-of-the-art technologies and their future prospects.

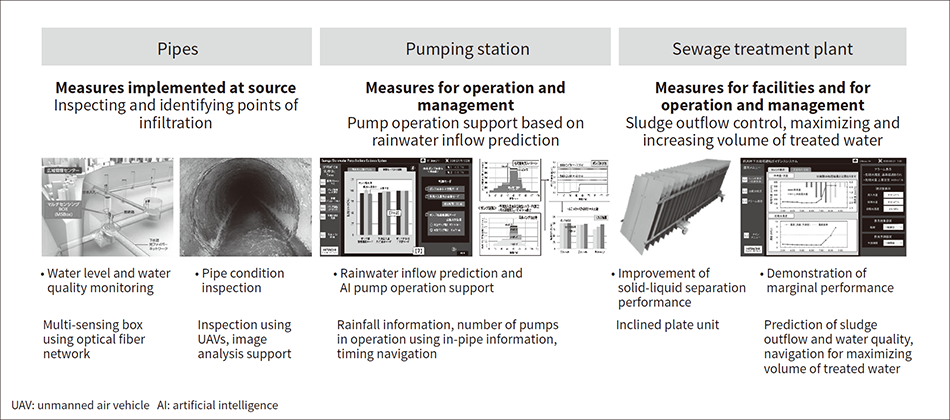

Amid a progressively changing climate and aging pipes, the Ministry of Land, Infrastructure, Transport and Tourism has issued draft guidelines on dealing with water inflows during rainfall events(2). In recent years, stormwater control measures have been implemented not only for combined sewer systems, but also for separate sewer systems. In addition to management technologies for pipes and pump stations, Hitachi is developing operation support technologies as stormwater management solutions for sewage treatment plants using model equations, AI, and other methods that focus on operation and management innovations, which are economical software measures combined with hardware measures that can be implemented with only minor modifications (see Figure 1). This section presents Hitachi’s stormwater management solutions for sewage treatment plants, which are responsible for purification in the treatment process.

Figure 1 — Hitachi’s Rainwater Solutions for Sewerage Systems (Including Those under Development and Verification) Hitachi provides a wide range of rainwater solutions to reduce rainwater risks in sewers.

Hitachi provides a wide range of rainwater solutions to reduce rainwater risks in sewers.

In the treatment process during rainy weather, activated sludge outflow from the final sedimentation tank must be controlled while maximizing biological treatment and reducing the discharge load associated with simple treatment discharge. To meet this need, Hitachi has developed and verified a inclined plate unit(3) that improves solid-liquid separation performance in the final sedimentation tank with minor modifications. It has also developed an operation support system(4) that derives the maximum treated water volume within a limited range by using model equations such as the sludge outflow estimation model(4). The sludge outflow estimation model reproduces the settling and advection of activated sludge in the final sedimentation tank and predicts the concentration of suspended solids (SS) overflowing from the final sedimentation tank.

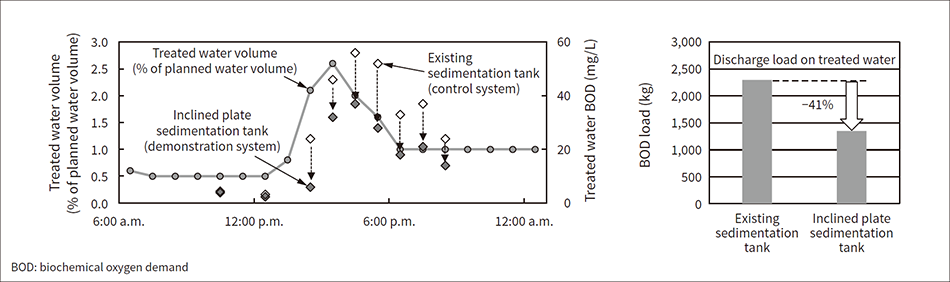

First, an example of the verification results of the inclined plate unit is shown in Figure 2. The inclined plate unit was installed in the final sedimentation tank of a sewage treatment plant (combined type) that had problems with solid-liquid separation performance in the final sedimentation tank. The quality of the treated water was compared with that of an existing sedimentation tank under the same operating conditions. As a result, the quality of the treated water in the inclined plate sedimentation tank was improved compared to the existing sedimentation tank, and the discharge load (from treated water) of biochemical oxygen demand (BOD), an indicator of organic matter, was reduced by 41%.

Figure 2 — Effect of Reducing Discharge Load by Installing Inclined Plate Unit (with Actual Equipment Verification Results) The increased solid-liquid separation performance of the inclined plate unit improved the quality of the treated water and reduced the discharge load of BOD on the treated water by 41% compared to the existing sedimentation tank (control system).

The increased solid-liquid separation performance of the inclined plate unit improved the quality of the treated water and reduced the discharge load of BOD on the treated water by 41% compared to the existing sedimentation tank (control system).

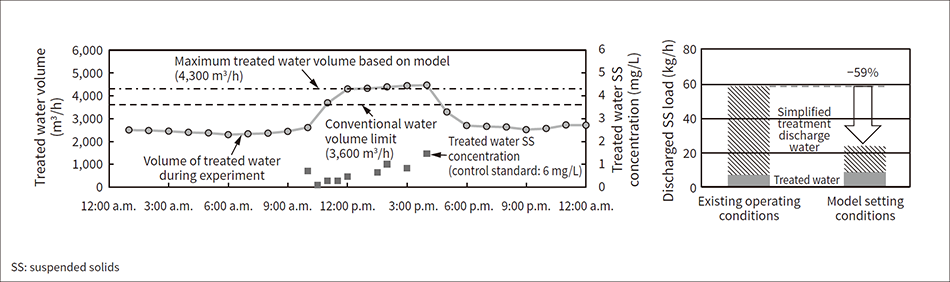

Next, Figure 3 shows the verification results of the operation support system. This is a separate sewer system, but in a sewage treatment plant where simple treatment discharge occurs during a heavy rainfall, the maximum treated water volume (1.2 times that of conventional systems, equivalent to a 70% reduction in the amount of simple treatment discharge) was derived within various constraints using various models, including a model for estimating sludge discharge. The validity of this finding was verified with actual equipment under operation. As a result, the treated water quality was below the control standard value, and the hourly discharge SS load (total of treated water and simplified treatment discharge water) could be reduced by 59% when discharging simplified treatment water. Consequently, this confirmed the validity and effectiveness of the model-based treatment water volume setting.

In the future, Hitachi will enhance the applicability of the developed technology by installing it in actual facilities and further verifying and improving it, thereby contributing to maintaining water quality, reducing the discharge pollution load, and improving operational efficiency in sewage treatment during rainy weather.

Figure 3 — Verification Results by Actual Equipment at Maximum Treated Water Volume Based on Sludge Outflow Estimation Model, Etc. Based on model calculations, the maximum water volume was set at 1.2 times the conventional volume (equivalent to a 70% reduction in simple treatment discharge), and verification was conducted using actual equipment. As a result, the SS concentration in the treated water was below the control standard (the same applies to organic matter, nitrogen, and phosphorus concentrations), and the SS load in the discharge was also significantly reduced.

Based on model calculations, the maximum water volume was set at 1.2 times the conventional volume (equivalent to a 70% reduction in simple treatment discharge), and verification was conducted using actual equipment. As a result, the SS concentration in the treated water was below the control standard (the same applies to organic matter, nitrogen, and phosphorus concentrations), and the SS load in the discharge was also significantly reduced.

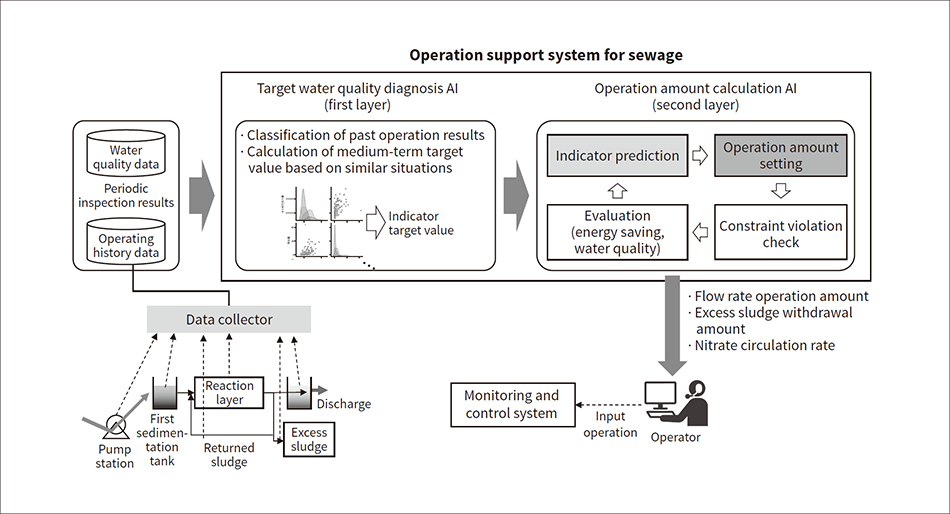

Figure 4 — AI-based Operation Support System for Sewerage Systems The first layer calculates the medium-term target values based on operating history data collected from the water quality data and monitoring and control systems. The second layer calculates the operation amount that will save energy in achieving the medium-term target.

The first layer calculates the medium-term target values based on operating history data collected from the water quality data and monitoring and control systems. The second layer calculates the operation amount that will save energy in achieving the medium-term target.

On a daily basis, sewage treatment plants use blowers to supply the air necessary for sewage purification and use pumps for sewage inflow. Traditionally, skilled operators have been responsible for this work, but currently, there is a shortage of operators due to the shrinking labor force. Expectations are therefore rising for AI-based support to improve maintenance and management efficiency and to pass on skills. Hitachi provides cloud-based digital solutions to support operation and maintenance (O&M), and is developing technologies to support maintenance and management operations from both facility management and operation and management perspectives. This section presents Hitachi’s AI-based operation support technology for sewerage systems.

The purpose of sewage treatment is to treat organic matter and nutrient salts such as nitrogen and phosphorus in sewage using activated sludge, which consists of microorganisms, and to purify the water to a quality that can be discharged into rivers. Good water quality can be obtained through the proper operation of blowers, circulation pumps, and other equipment, but qualitatively, there is a trade-off between water quality and energy usage. Therefore, the challenge is to set the target water quality within a range that does not affect the environment, and then to run the equipment in an energy-efficient manner with reduced operation. To address this issue, Hitachi is developing a hybrid operation support system that combines human knowledge of sewage treatment and AI (see Figure 4).

In this system, the first layer (AI diagnosing target water quality) first analyzes the operating history of past sewage treatment plants based on the physical and chemical characteristics of sewage treatment and human knowledge, and establishes medium-term target values for water quality according to the season. Next, in the second layer (AI calculating the operation amount), the system learns operational data of sewage treatment facilities obtained at regular time intervals, and maintains a prediction AI that estimates the state of the facilities when certain operations are performed. Using this prediction AI, an optimization AI is used to find the equipment operation amount that saves energy within the range where no abnormalities in water quality occur (i.e., no deviation from the medium-term target values derived by the AI that diagnoses the target water quality), thereby realizing energy-saving operation.

Hitachi is participating in a joint research project for practical application of AI-based sewage treatment to verify the effectiveness of the developed technology conducted at the Arakawa Water Cycle Center (located in Toda City, Saitama Prefecture and having a treatment capacity of approx. 950,000 m3/day), managed by the Saitama Sewage Systems Agency. This joint research will apply AI to some of the sewage treatment lines at the Center and run them on a trial basis for one year to study whether they can reduce greenhouse gas emissions, lower maintenance and management costs, and improve operational efficiency. The demonstration system has been operating during the evaluation period, from January 2022 to January 2023 (as planned at the time of proposal) to confirm the effectiveness.

In sewage treatment projects in Japan, as the population declines and sewage fee revenues decrease(5), improving profitability by streamlining sewage treatment and reducing maintenance and management costs is an urgent issue. Among these costs, sludge disposal costs account for a relatively high proportion of total maintenance and management costs, and recent trends suggest that efforts to reduce sludge disposal costs by using full-service private-sector outsourcing will accelerate in the future(6).

This study focuses on the dewatering process and dewatering machine operation, which are standard parts of the sludge treatment process for developing service business and technology by optimizing this process using Internet of Things (IoT) and AI technologies.

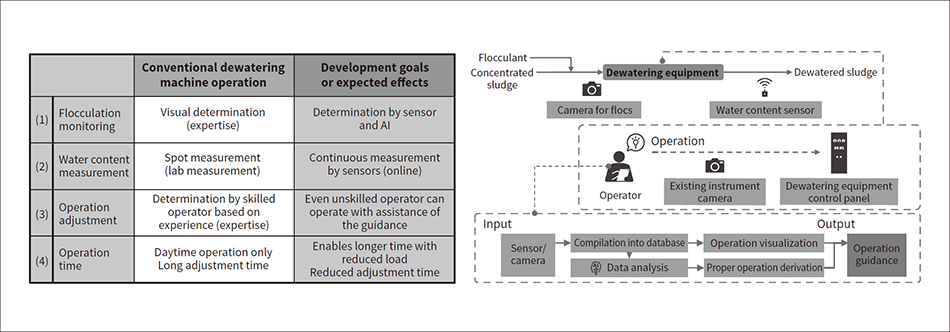

Filtration-type dewatering machines, such as screw presses, have the characteristic of increasing the dewatering rate by properly conditioning the dewaterability of sludge through pretreatment such as flocculation, and by increasing the pressing pressure and pressing time(7). On the other hand, two issues that arise are that (1) the dewatering machine has been operating based on the settings configured at start-up, making it difficult to perform conditioning and operation according to changes in sludge dewaterability, and (2) only a limited number of operators understand the details of the dewatering machine and are able to operate it during the hours when skilled operators are working. Therefore, with the goals of detecting changes early in the dewaterability of sludge and enabling even unskilled operators to operate the dewatering machine with operation guidance, Hitachi has developed a sensor capable of monitoring flocculation by AI-based image analysis and online continuous measurement of water content (percentage of water content in the sludge after dewatering) as an indicator of dewatering success or failure. It has also developed dewatering machine operation guidance based on analysis of accumulated data (see Figure 5).

Figure 5 — Configuration and Role of Dewatering Machine Operation Guidance With the goals of detecting changes early in dewaterability of sludge and enabling even unskilled operators to operate the dewatering machine with operation guidance, Hitachi has developed a sensor capable of monitoring flocculation using AI-based image analysis and online continuous measurement of water content and has developed dewatering machine operation guidance based on the analysis of accumulated data.

With the goals of detecting changes early in dewaterability of sludge and enabling even unskilled operators to operate the dewatering machine with operation guidance, Hitachi has developed a sensor capable of monitoring flocculation using AI-based image analysis and online continuous measurement of water content and has developed dewatering machine operation guidance based on the analysis of accumulated data.

In the dewaterability conditioning process by flocculation, the dewaterability of sludge can be estimated by means of sedimentation tests of flocs (particle masses produced by flocculation). However, because the tests are time-consuming, the quality of the sludge is determined by visually inspecting the flocs, which is dependent on the expertise of skilled workers. Therefore, Hitachi is studying the image analysis of flocs to see if it is possible to extract features that correlate well with the dewaterability of sludge from image data acquired by a camera.

Also, because it takes time to measure water content in the laboratory and obtain the results, dewatering is determined onsite based on the feel and appearance of the dewatered sludge, which is dependent on the expertise of skilled workers. Consequently, Hitachi is developing a sensor based on near-infrared spectroscopy for on-line continuous measurement of water content. In this development, Hitachi is studying how to attain measurement accuracy that enables practical use even with a relatively inexpensive spectrometer by devising a method for analyzing the spectra measured by the spectrometer.

Furthermore, Hitachi is examining the possibility of using AI to build operation guidance for dewatering machines based on the data accumulated by combining existing instrument data with the results of image analysis of flocs and water content sensor data. In particular, continuous measurement of dewaterability and water content of sludge, which until now could only be obtained at a few points per day, is expected to improve the quality and quantity of data and increase the accuracy of AI analysis.

This technology is being developed for release in FY2023 as a service business for reducing sludge.

This article presented an overview of innovative digital-based technologies that are necessary to continue to provide a safe, secure, and sustainable sewage infrastructure. Based on its extensive track record in products, systems, and services in the water infrastructure field, the Hitachi Group intends to continue contributing to the fulfillment of the mission of sewerage systems, which is to help build a society capable of sustainable development.