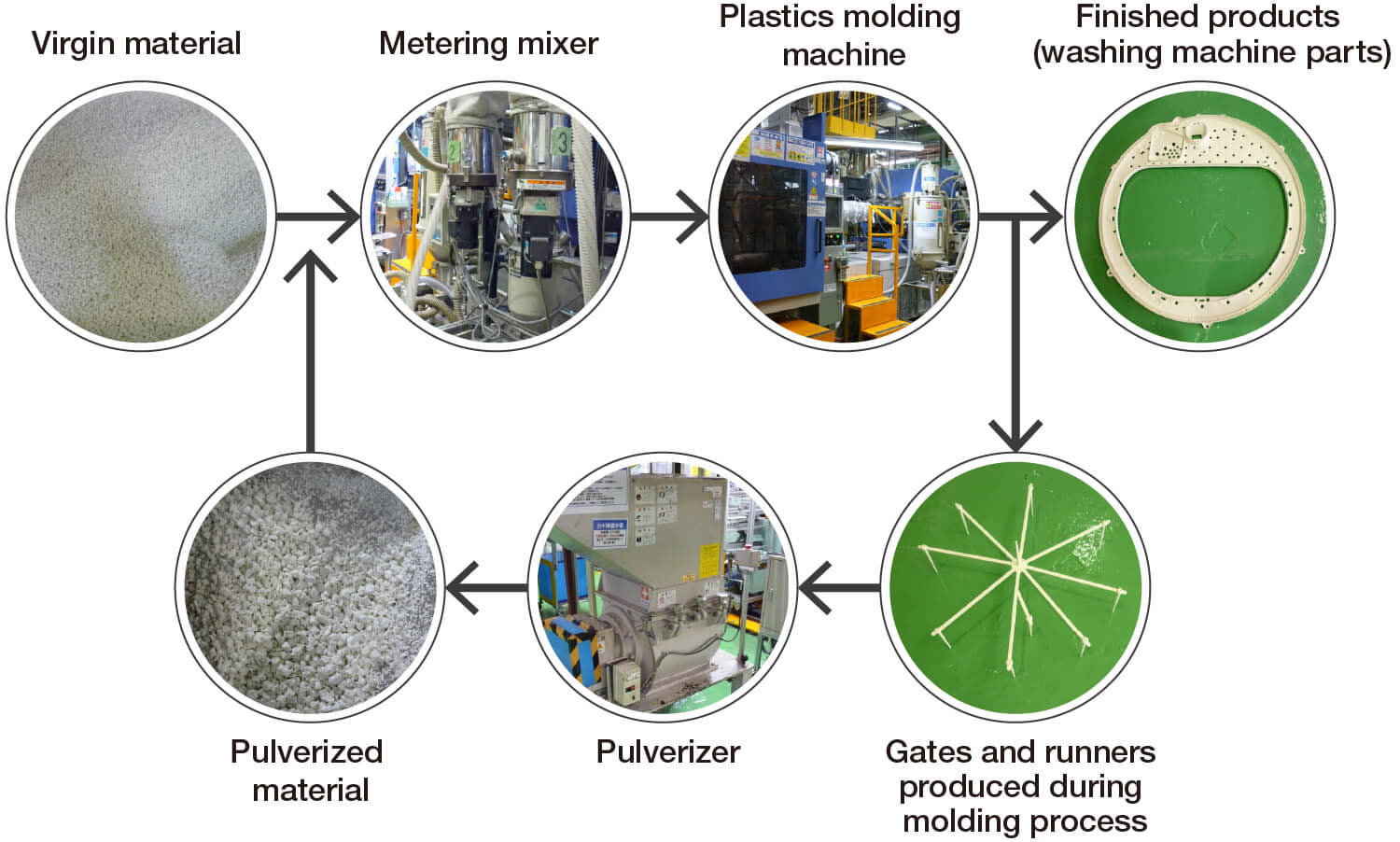

The Taga Works of the Hitachi Global Life Solutions, Inc. manufactures products including washing machines, cleaners, rice cookers, air purifiers, and IH cook tops. In order to effectively utilize the gates and runners*1 that are created as byproducts of the plastic molding process used to create the plastic components for these consumer electronics, the plant has installed a pulverizer adjacent to the production line.

This initiative has enabled some of these gates and runners, which were previously shipped to other companies and plants for recycling, to be recycled immediately in the same production process. Thanks to this, the plant recycled 199 tons of plastic from gates and runners in fiscal 2020, improving yield.*2