BESSs are attracting increased attention as a means of providing the balancing capacity needed to deal with the fluctuating output of renewable energy to realize power grids with high penetration of renewable energy. In order to ensure that BESSs have a long operating life and are profitable for their owners and comply with the grid constraints, there is a need for operating conditions to be optimized by diagnosing the internal state of the batteries and predicting their remaining useful life for various different charging and discharging patterns. Hitachi has been collecting battery performance and degradation information at all levels from materials to cells and systems over many years. It has also developed discharge curve analysis as a fundamental technique for battery diagnosis and control and then used it for remaining useful life diagnostics and capacity recovery. Hitachi has also applied diagnostics technology to energy management to demonstrate the validity of an imbalance risk-free system utilizing an internal balancing capacity owned by customer.

The supply and consumption of primary energy is undergoing major structural changes around the world in pursuit of carbon neutrality. Forecasts by the International Energy Agency (IEA)(1) anticipate a major reduction in the use of the fossil fuels that currently supply more than 80% of energy needs, with renewable energy such as wind turbine- and photovoltaic-power-generation becoming a major source for power grids. As grid instability is one of the challenges that come with this greater use of renewable energy, the large-scale installation of batteries is being looked at as a solution to the problem of output that fluctuates depending on weather conditions when less thermal generation capacity is available for balancing(2). Connecting electric vehicles (EVs) to the grid is one way of using batteries for this purpose, a technology that is called “vehicle to everything” (V2X)(3). There has also been progress on installing battery energy storage systems (BESSs) as a reliable source of electric power that is permanently connected to the grid(4). As the batteries used in EVs and BESSs need to be compact and able to keep up with erratic changes in electricity supply and demand, lithium-ion batteries (LIBs) are widely used in these roles because of their superior energy and power densities. The market for lithium-ion BESSs targeted at consumers and generation or transmission system operators is expected to grow at an annual rate of more than 20%. Maintaining this market growth will require that BESS owners gain economic benefits from installing and operating these systems. This in turn calls for control of installation and operating costs while also boosting revenue by using BESSs to trade on electricity markets. Achieving this will require the ongoing diagnosis of battery performance and safety as these degrade with use, and also the ability to predict how the remaining useful life of batteries is influenced by how they are used. Given these capabilities, operating plans can be created that ensure both long battery life and profitability for owners.

Based on its data and knowledge of battery degradation at the material level acquired from work on the development of lithium-ion cells and materials for automotive, consumer, and industrial uses, Hitachi has developed proprietary techniques for battery diagnosis and control that it is deploying in the energy storage system(4), railways(5), and construction machinery(6) industries. This article describes the core technologies for LIB diagnosis and control as well as a trial of their application to energy management in a system for eliminating imbalance risk that utilizes consumers’ own balancing capacity, including EVs and BESSs.

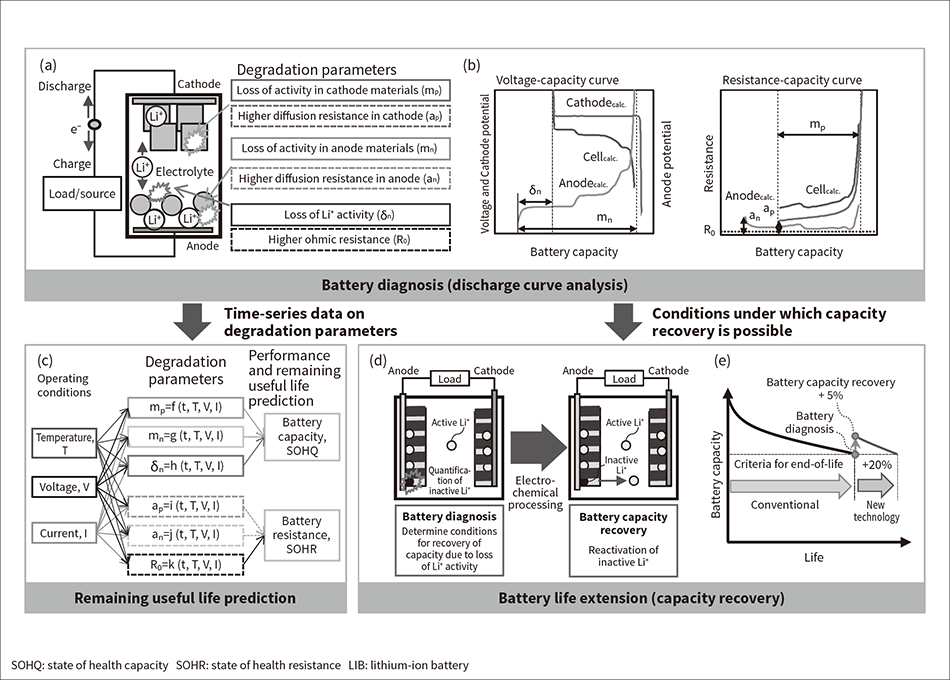

Figure 1 — Hitachi’s Core Techniques for Diagnosis and Control of LIBs Diagrams (a) and (b) show battery condition diagnosis. Material degradation in the battery can be estimated in the form of quantitative degradation parameters from the voltage-capacity and resistance-capacity curves obtained when charging and discharging. Diagram (c) shows remaining useful life diagnostics. By determining the dependency of these degradation parameters on operating conditions, it is possible to predict the changes in performance associated with multiple forms of material degradation. Diagrams (d) and (e) show how battery life can be extended. Degraded battery capacity can be partially recovered and the battery’s life extended by manipulating the current based on the degradation parameters.

Diagrams (a) and (b) show battery condition diagnosis. Material degradation in the battery can be estimated in the form of quantitative degradation parameters from the voltage-capacity and resistance-capacity curves obtained when charging and discharging. Diagram (c) shows remaining useful life diagnostics. By determining the dependency of these degradation parameters on operating conditions, it is possible to predict the changes in performance associated with multiple forms of material degradation. Diagrams (d) and (e) show how battery life can be extended. Degraded battery capacity can be partially recovered and the battery’s life extended by manipulating the current based on the degradation parameters.

Figure 1 shows some of Hitachi’s core technologies for LIB diagnosis and control. The degradation of battery materials during operation depends on the operating conditions, and causes the loss of charge and discharge capacity and decreased efficiency of charging and discharging modes due to increased internal resistance. Hitachi has developed a technique called discharge curve analysis that can non-destructively identify degradation at the material level based on voltage-capacity and resistance-capacity curves for in-use LIBs(7) [see (a) and (b) in Figure 1]. This analysis extracts the parameters listed in Figure 1 (a) as indicators of material-level degradation. As these degradation parameters influence the voltage-capacity and resistance-capacity curves shown in Figure 1 (b), they can be estimated from curve analysis obtained during battery operation and used to determine the degree of degradation for each material. While similar diagnostic techniques have been widely investigated(8), a feature of Hitachi’s technique is its broad applicability. Most of the diagnostic methods reported in the literature(9), (10) focus on the ternary lithium batteries that are widely used in automotive applications, namely those that use Li(NixMnyCoz)O2 in the cathode. This is because the strong correlation between voltage and capacity makes the diagnosis of this type of battery easy. On the other hand, in battery cell with a lithium iron phosphate (LiFePO4) cathode, which contains less rare metals and exhibits the better life and cost performance, the dependence of the voltage on the capacity is relatively low. This correlation makes the diagnosis of these batteries difficult. Instead, Hitachi has been able to identify degradation parameters for these batteries by also considering the resistance-capacity curve, focusing on resistance as a more sensitive indicator of capacity(11), (12). This method has the potential to provide precise diagnostics for the diverse range of LIBs in use by customers and on the grid.

The method can be used not only for diagnostics, but also for the prediction of remaining useful life [see Figure 1 (c)]. The degree of battery degradation during BESS operation depends on the operating conditions (time-series data such as temperature, voltage, and current). Hitachi’s diagnostic technique makes it possible to formulate the correlation between the operating conditions and the degradation parameters, which achieve the prediction of battery degradation even when various degradation reactions take place. These features allow this technique to be applied not only to the aging-aware design of BESSs, but also to efficient planning and operation considering the remaining useful life.

Other recent work has focused on partial recovery of degraded battery capacity based on the degree of material-level degradation, thereby extending battery life [see Figure 1 (d) and (e)](13). Loss of lithium ion (Li+) activity, one of the forms of degradation listed in Figure 1 (a), occurs when the ions become trapped in the anode where they are no longer able to contribute to charging and discharging. While it is possible to recover battery capacity by discharging beyond the lower voltage limit that applies in normal use and then temporarily raising the anode potential to expel these inactive Li+ ions, this raises concerns that the excessive discharge will cause other materials to degrade or that it will increase the safety risk. By using the degradation parameters obtained by the diagnostic technique described above as a basis for selecting the recovery conditions, Hitachi has demonstrated that it is possible to extend battery life while suppressing material degradation and safety risk. This has the potential for application in future systems.

If a higher proportion of energy is to be derived from renewable sources, electricity retailers will need to acquire the balancing capacity needed to maintain grid stability. Hitachi has developed an imbalance-risk-free system (IBRFS) that allows electricity retailers and consumers to collectively balance their combined supply and demand, and that compensates customers for the economic cost of imbalances (imbalance risk)(14). Figure 2 shows a block diagram of the system. Consumer equipment includes a range of loads (lighting and air conditioning), photovoltaic (PV) power generation systems, and battery systems (bidirectional EV chargers and BESSs). The different energy management systems (xEMSs) operated by individual consumers collect data on equipment operation and on electricity consumption at the point of grid connection, passing this information to a supervisory EMS that controls operation in a way that eliminates the imbalance risk across multiple consumers. This supervisory EMS uses electricity procurement plans received from electricity retailers and data on actual demand received from the xEMSs to identify imbalances in supply and demand. It then determines how much balancing capacity can be provided by each item of equipment and issues instructions to the xEMSs accordingly. This system configuration features a high level of responsiveness and can deal with imbalances on its own, without having to go through the balancing market.

Unfortunately, because deploying balancing capacity unnecessarily can degrade equipment performance, risking a loss of remaining value, it is important to determine in advance whether the use of equipment for this purpose makes economic sense. The IBRFS uses balancing capacity price as a criterion for deciding whether equipment can be used. In the case of an electrical load, the balancing capacity price is defined as its electricity and other operating costs, whereas for a battery storage system it is the amount, per unit of energy (kWh), by which the residual value of the batteries is diminished by the degradation caused by charging and discharging. Which equipment to deploy for balancing can then be determined by comparing this balancing capacity price against the imbalance risk.

The sequence of steps for calculating the balancing capacity price for a BESS is as follows. In the case of charging, the price is calculated using formula (1) below. Discharging uses the same formula, only with different coefficient values.

CbattDR_charge = kcharge(SoC, T) × Cproduct/QRemaining (1)

CbattDR_charge is the base price for balancing capacity provided by a BESS and kcharge is a correction coefficient for increasing the frequency of balancing capacity deployment that depends on the battery’s state of charge (SoC) and temperature. Cproduct is the current value of the product (BESS) and is calculated using formula (2) below by amortizing its cost of purchase over its anticipated operating life. Here, Cproduct_ini is the cost of purchase, tLife is the anticipated operating life (years), and tproduct is the number of years the BESS has already been in use.

Cproduct = Cproduct_ini(1 − tproduct/tLife) (2)

QRemaining is the capacity (kWh) remaining over the life of the BESS. Calculated using formula (3), it represents the total amount of charging and discharging (kWh) that the battery can undergo before it reaches its end-of-life level of degradation.

QRemaining = QLife – Q (3)

QLife is the amount of energy that can be charged and discharged over the battery’s entire life, and Q is the amount used to date. QLife is calculated from the operating conditions using a life prediction formula. The economic benefit to the customer can be underpinned by using the degradation diagnosis and remaining useful life prediction techniques described above to calculate a highly accurate value for QLife.

The IBRFS trial described above studied the use of balancing capacity price as a criterion for responding to imbalances, using equipment installed at the research facility for this purpose, including EVs, a BESS, and other equipment likely to be found at a consumer site. Figure 3 (a) shows time-series data for the imbalance risk and the balancing capacity prices (JPY/kWh) for a stationary LIB and EVs calculated by formula (1). The imbalance risk is the FY2020 imbalance price multiplied by a correction coefficient. This coefficient defines the margin by which the imbalance price is expected to increase relative to the historic price. Whether or not each item of equipment should be deployed for balancing is determined by comparing this imbalance risk against its respective balancing capacity price. Figure 3 (b) shows how battery storage is charged or discharged to provide balancing capacity. Charging starts automatically to provide balancing capacity as soon as the imbalance risk increases beyond the battery’s balancing capacity price, which occurs at timing (1) in the graph. As charging progresses, however, the degradation risk to the battery increases as its SoC rises, thereby increasing its balancing capacity price for charging. Accordingly, charging halts at timing (2) where this price rises above the imbalance risk.

In this way, the trial demonstrated that, by calculating accurate prices for balancing capacity and comparing these against the imbalance risk to determine which equipment to deploy, the customer’s equipment can be operated in a way that maximizes revenue based on this comparison.

This article has reported on the demonstration of a system to optimize asset operation as internal balancing capacity based on the comparison between balancing capacity prices and imbalance risk as an example of the application of LIB technologies to energy management.

The technique for predicting remaining useful life serves as the basis for setting balancing capacity prices. Improving its accuracy and expanding the scope of application is important to improve the owner’s revenue without compromising grid constraints and product life. To this end, Hitachi intends to contribute to enhancing customer value by further increasing the sophistication of diagnosis and control techniques for LIBs.