To maximize the effective use of nuclear power—a decarbonized energy source—there is a growing need to improve equipment reliability and optimize maintenance. This is essential for increasing operational availability through shorter outage inspection periods and long-cycle operations.

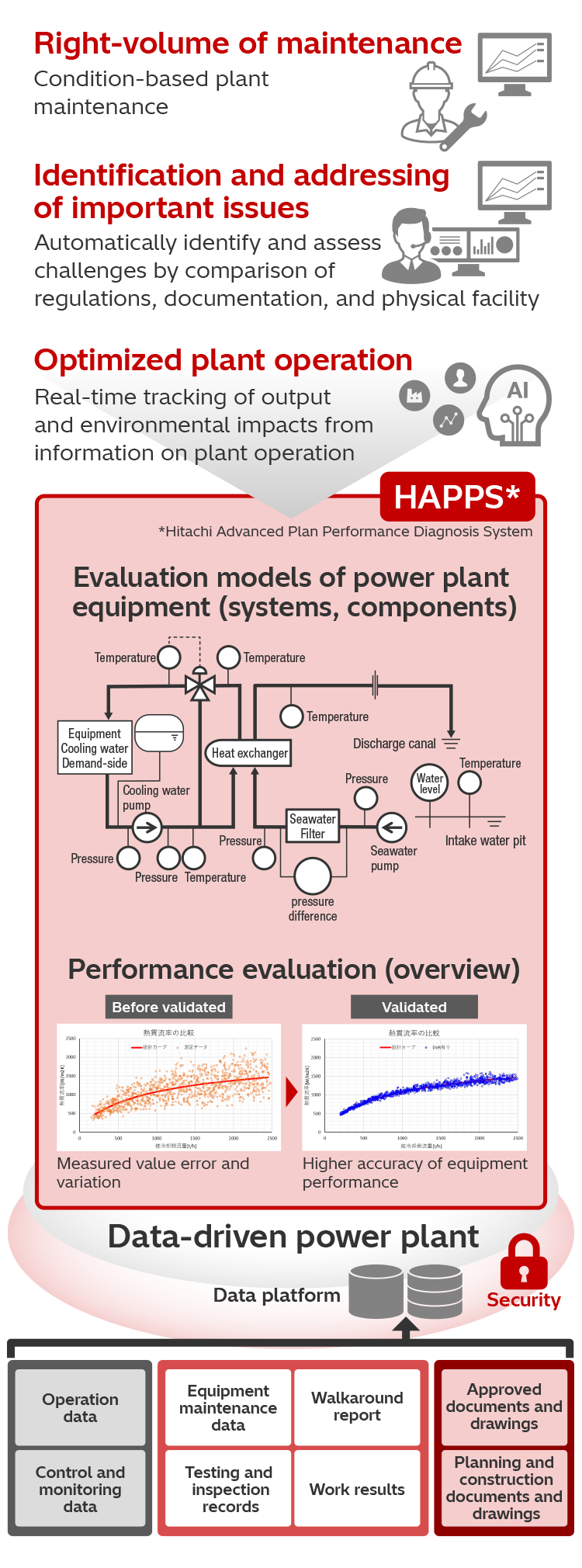

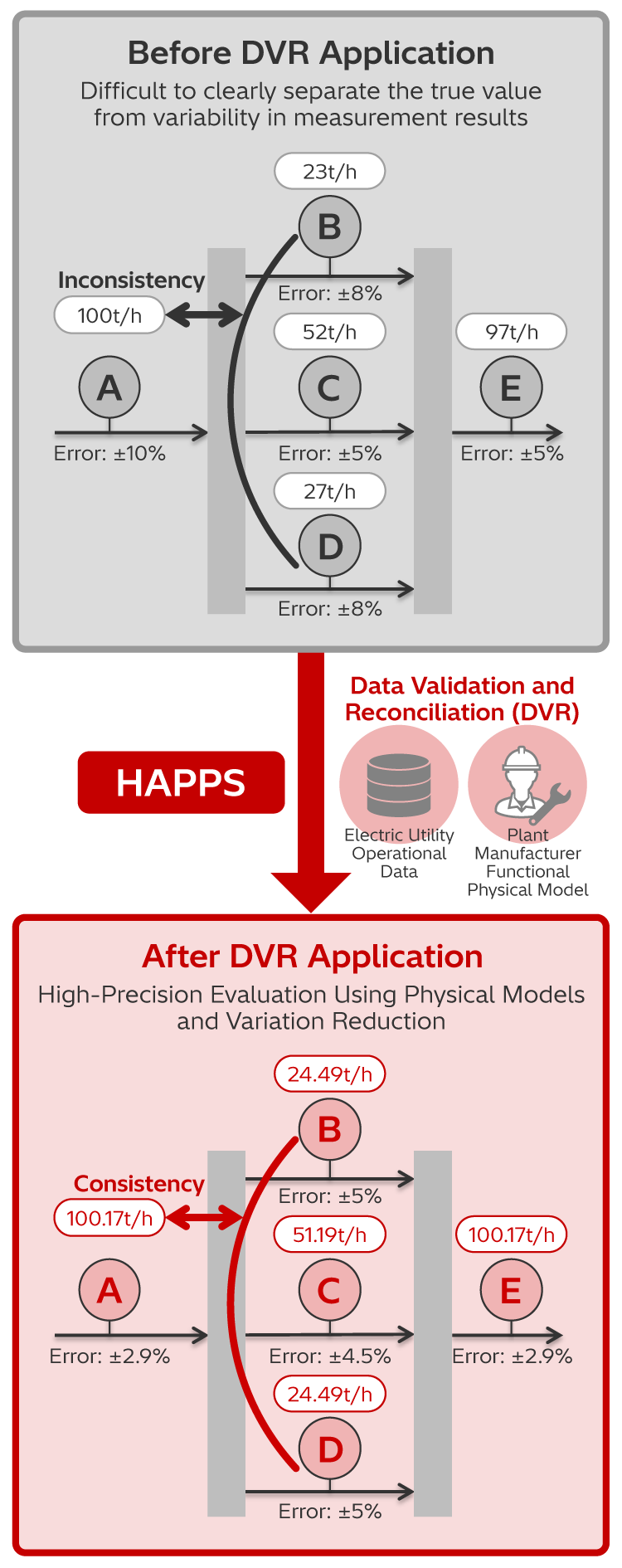

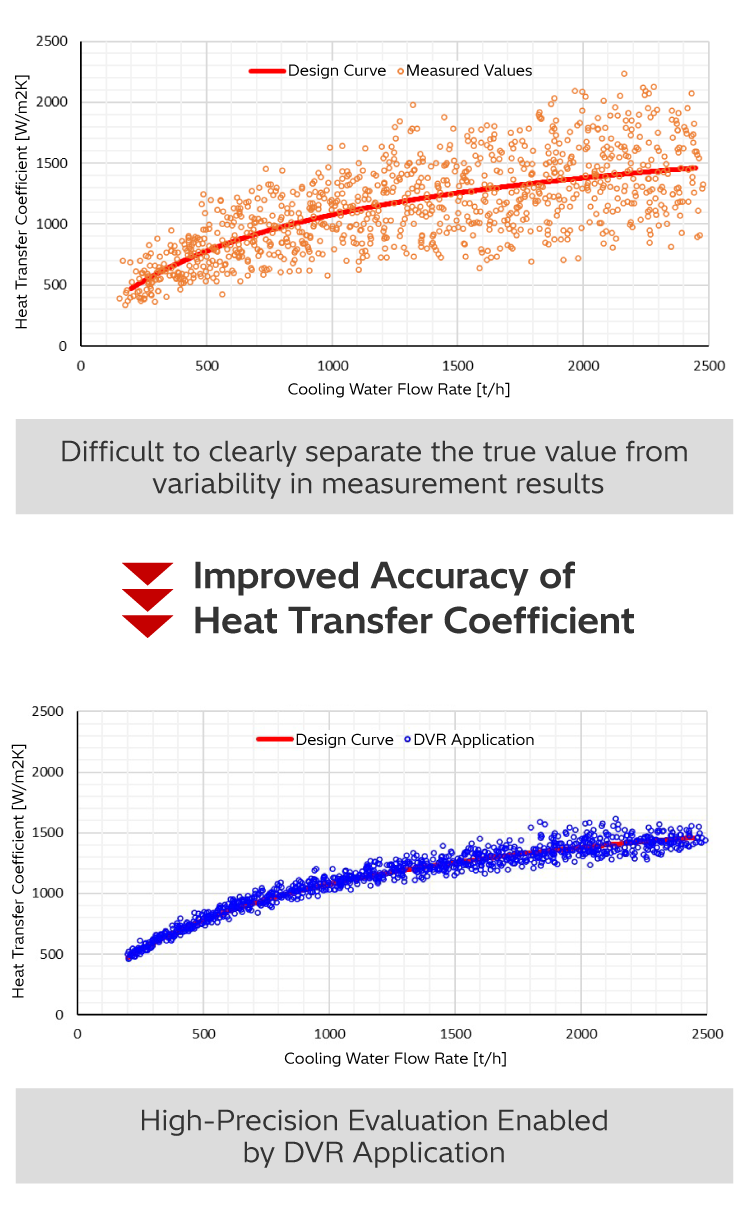

Hitachi has developed the Hitachi Advanced Plant Performance Diagnosis System (HAPPS), which utilizes Data Validation and Reconciliation (DVR) techniques to estimate the “most probable state” of the plant.

HAPPS enables:

These capabilities contribute to improved operational availability, optimized maintenance, and enhanced power generation efficiency at nuclear power plants.