Hitachi developed "Metaverse Platform for Nuclear Power Plants" utilizing metaverse and AI solutions.

The platform is designed to serve as a foundation for a “Data-Driven Power Plant,” which aims to address the diverse needs and challenges faced by elenctic utilities—such as improving equipment reliability, enhancing work management, and increasing operational efficiency—through data-driven value creation and problem-solving. The platform facilitates the collection, aggregation, and analysis of on-site data, thereby supporting optimal investment planning and plant maintenance through data-driven insights.

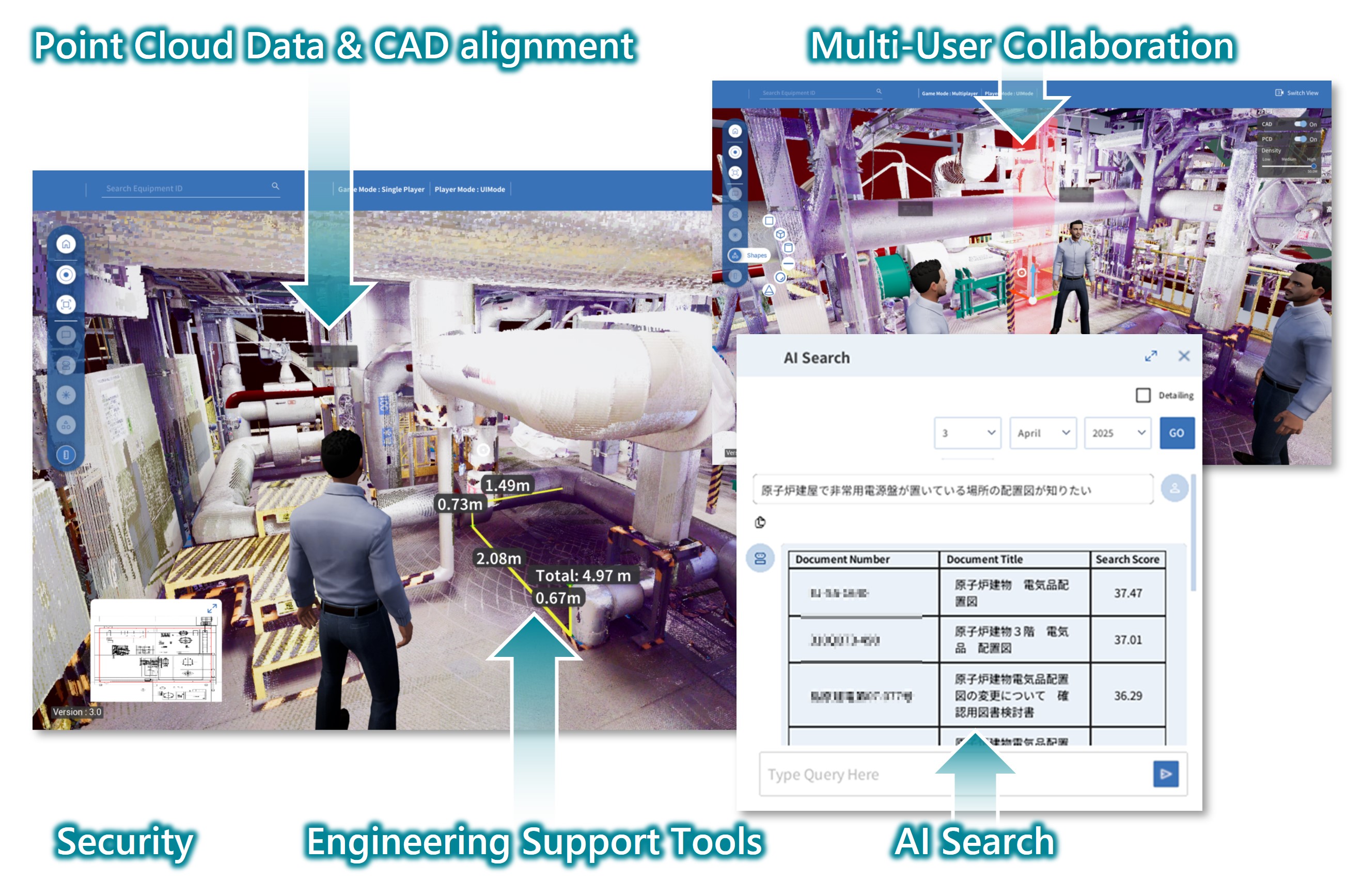

Overlays high-precision, high-density point cloud data*1 and 3D CAD*2 models to recreate nuclear power plants in a metaverse. This enables precise verification of site conditions and identification of discrepancies between drawings and actual structures.

Incorporates natural language processing to allow full-text and synonym-based searches of design documentation. Location and equipment-specific data in the metaverse enhances search accuracy.

Supports simultaneous access to the metaverse by multiple users, facilitating real-time communication and decision-making across geographically dispersed stakeholders.

Offers centimeter-level measurement capabilities, virtual meetings, annotation, file attachment to specific equipment or areas, equipment layout search, and asset linking functions to assist engineering operations.

Ensures secure communication through encrypted interactions in the metaverse and access control limited to authorized users.

*1 A dense collection of spatial points captured by 3D scanners or cameras, used to represent the shape of objects or environments in three dimensions.

*2 Computer Aided Design software used for creating and editing engineering drawings and models digitally.

Image of virtual spaces recreated on-site and related functions in the Metaverse Platform for Nuclear Power Plants