Hitachi's OT

Hitachi's OT (operational technology) was born from its

MONOZUKURI (manufacturing) technologies.

Hitachi seamlessly connects OT and IT for optimal solutions in the field.

Here, OT (Operation Technology) is defined as hardware and software technologies

that monitor and control physical equipment and processes.

This refers to the Control and Operation Technologies that optimally run essential equipment and systems for

the operation of social infrastructure, such as electricity, railways, iron and steel, and water, and industrial plants.

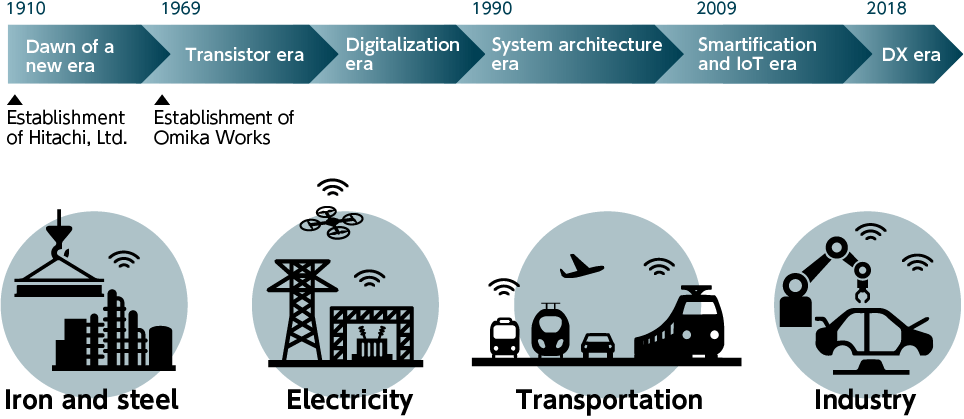

The long history of OT at Hitachi begins with the production of electric motor control devices and switchboards from around 1914, just after the establishment of Hitachi, Ltd. in 1910. The dawn of control systems started with the control of rolling mills at steel factories, and in the subsequent transistor era, electrical power safeguard control systems drove the development of control technologies. Then in the digitalization era, digital computers for control appeared, and as a result, the scope of control expanded to the field of electricity, such as power generator control and system control, and to the field of transportation, such as railway operation management. Afterward, control system architecture including integration and autonomous decentralization, was established in a variety of fields including electricity, transportation, industry, and water and sewage systems. Now in the smartification, IoT, and DX eras, the evolution of control system architecture continues as information control systems.

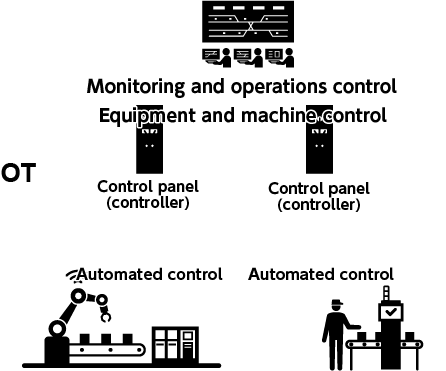

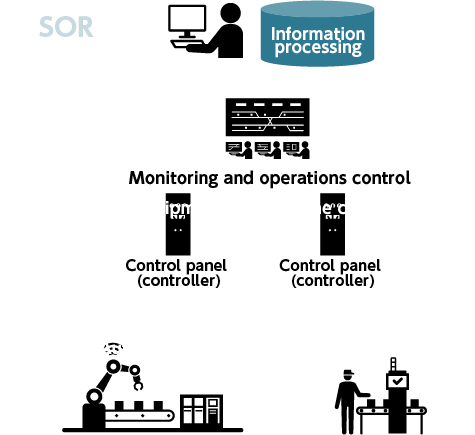

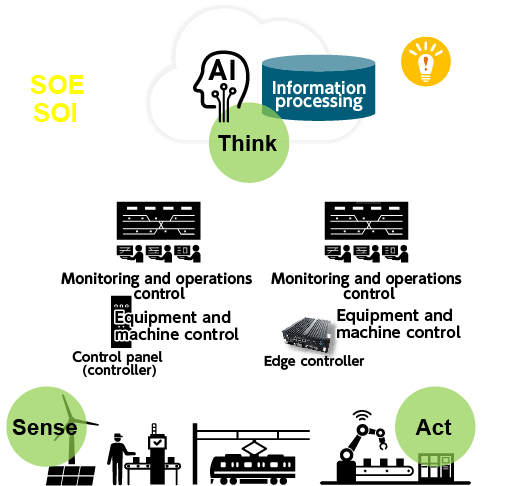

When comparing control systems (OT systems) to information systems (IT systems), the processing target of IT systems is information, while the processing target of OT systems is physical phenomena, such as equipment and machinery. In addition, the prioritized system requirements of IT systems differ for each system design concept of SOR, SOE, and SOI, but because lives are at stake due to machine accidents, when it comes to OT systems, safety is always prioritized by the system requirements, and any delays in real-time processing are unacceptable. Furthermore, OT systems are required to operate over the long term, so maintainability and expandability are also important for repeated expansion, extension, and remodeling while continuing operations.

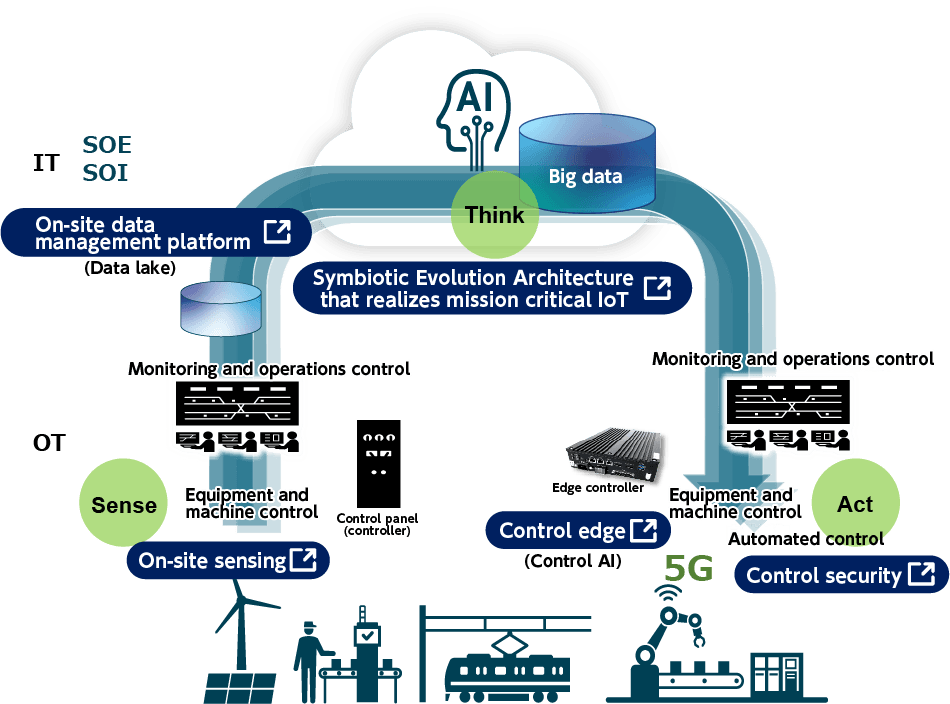

In addition, while technological progress, such as cloud, big data, and AI, has also rapidly become standard for IT systems, for OT systems, native technologies and operational expertise are required for each control target. Specialized OT knowledge in each field and the practical ability to make use of advanced IT are required in order to analyze and use on-site data to upgrade the operation of OT systems.

SOR: System of Record

SOE: System of Engagement

SOI: System of Insight

Since its establishment in 1969, Hitachi, Ltd. Omika Works has been providing information control systems that integrate control devices and various types of systems for the field of social infrastructure, such as electricity, railways, water and sewage, and iron and steel.

The information control systems provided by Omika Works for social infrastructure are based on system requirements of diversity (each product is customized), reliability, safety, availability, expandability, maintainability, and business continuity as absolute qualities to realize 24-hour continuous operation and long-term operation at the core of social infrastructure and industrial plants, and require MONOZUKURI (manufacturing) to support these requirements.

Omika Works possesses a number of control system engineers who have excellent domain knowledge, and carries out total support for information control systems, including the development and production of control panels, such as control components (computers, controllers, etc.), the development of software for optimal control methods, such as modeling and analysis of control targets, quality assurance utilizing verification technologies such as simulations, and support for operations and maintenance in order to realize the functions, performance, and specifications required for control.

In this way, Omika Works, which promotes initiatives for the stable supply and operation of social infrastructure information control systems and practices the integration of operational technology (OT) and information technology (IT), was selected by the World Economic Forum (WEF) in January 2020 as a Lighthouse (one of the world's most advanced factories). Omika Works is the first Japanese company to be designated as a Lighthouse.

Seamlessly connecting OT and IT to realize dynamic capability

Traditionally, control systems have guaranteed absolute quality of hardware and software for continuous 24-hour operation, and guaranteed maintainability and expandability for long-term operation.

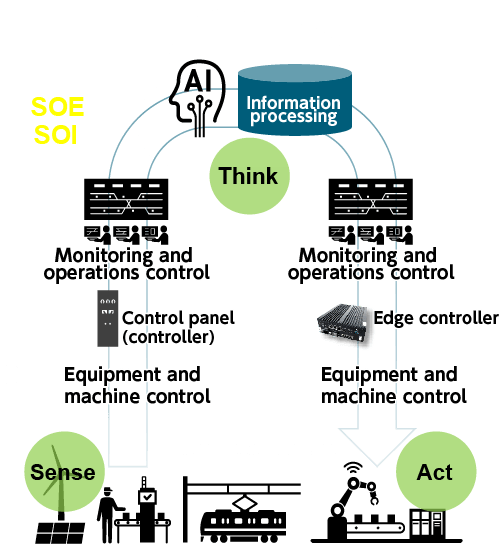

Through the progress of IoT adoption, the utility value of IT systems is shifting from SOR to SOE and SOI. Instead of individual optimization, a wider scope of optimization overall has enabled the establishment of hypotheses and enhancement proposals. In the OT field, sensing of physical phenomena creates data, the collected data can be then analyzed in the IT field, and the results are fed back into the system. This is known as the Sense-Think-Act data analysis loop, which has realized the optimization of operations of information control systems.

In the coming age of uncertainty, companies and systems are required to reform so that they can derive optimization solutions by continuously seizing and analyzing changes in the world on a short cycle, and automatically apply these solutions to the field. In order to realize this, Hitachi uses mission critical IoT systems that seamlessly connect OT and IT through software and digitalization to rapidly respond to social issues and business issues in the age of uncertainty, thus contributing to the development of sustainable social and industrial infrastructure.