Dialogue with the Chief Lumada Business Officer

2022-05-18

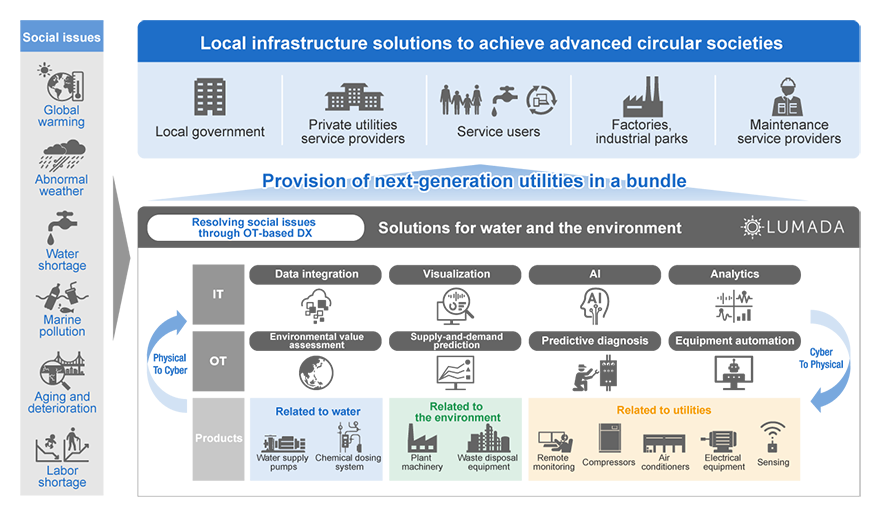

The Water & Environment BU*1 of Hitachi, Ltd. (hereinafter Hitachi) aims to use data to create circular economies for entire regions, starting with a circular economy for water. Supporting this goal are the track record and know-how Hitachi has built up as a provider of total, comprehensive water services that combine OT*2, IT, and products. Additionally, through Lumada, the BU has been accelerating the establishment of hydrogen value chains for zero-carbon cities, the use of AI to maintain and enhance infrastructure, and other initiatives to create a resilient society. Atsushi Ishii (Chief Lumada Business Officer of the Water & Environment BU) and Madoka Sawa (Lumada Innovation Evangelist) sat down to discuss these initiatives.

―As a provider of comprehensive water services, Hitachi’s Water & Environment BU has as its mainstay businesses the provision of clean water and the provision of clean environments for the equipment and facilities of industrial customers. Can you first share with us some of the challenges you face with respect to Hitachi’s water-related businesses?

Ishii: For about a hundred years, Hitachi has been involved in water-related businesses and helping to create clean water, mainly by providing electrical equipment, water treatment equipment, pumps, and other machinery for water purification and sewage treatment plants. Our activities are not limited to just water and sewage in Japan, but also include the installation of sewage treatment facilities in Papua New Guinea and the provision of tap water by using desalination equipment in the Maldives, to name a few examples. We’re helping develop water environments all around the world.

People say that the taste of water in Tokyo and Osaka has improved compared to about 20 years ago. In fact, the reason for that is Hitachi technology that uses ozone to purify and deodorize water. These days, the taste of Tokyo’s tap water can compete even with that of mineral water. On occasion, the tap water might be a bit cloudy or discolored, but in most of those cases, the cause of the problem lies with the water pipes, rather than with the water itself.

Sawa: So, aging water pipes are a problem?

Ishii: Across the country, the number of large-scale water leaks from old water pipes is on the rise, becoming quite problematic.

Sawa: In the first place, it’s quite hard to use and maintain things like pipes and cables, which are very long, right? In my own work related to the data center of an IT company, I struggled for many years with the maintenance of submarine communications cables. When it comes to long things like pipes and cables, it’s quite inefficient to have to perform all maintenance operations manually.

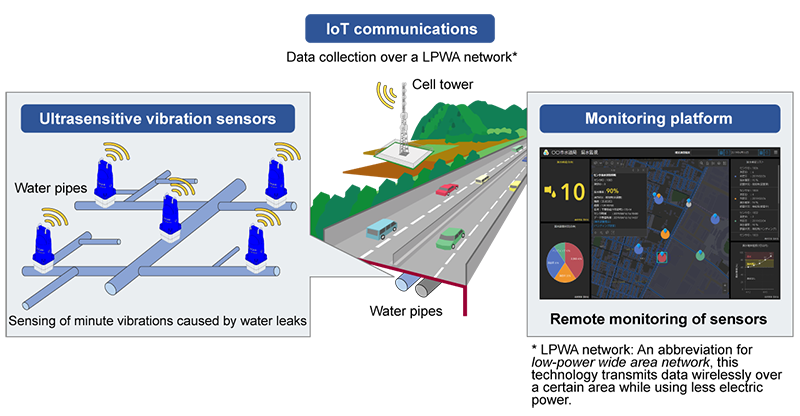

Ishii: Exactly. That’s why we are currently developing and verifying a water-leak detection service. With this service, we attach ultrasensitive vibration sensors, which were developed by Hitachi, to water pipe valves beneath manholes. This lets us determine whether water is leaking. Customers have told us that the service can detect water leaks with extremely high precision.

Sawa: I imagine this service will become more and more important in the future. It’s a great feat to be able to identify water leaks by using sensors, without having to demolish buildings or break up roads.

Ishii: Currently, water leaks are detected by having experts from water-leak detection companies walk the roads at night, listening for the sound of leaks. With our service, however, you’d be able to pinpoint and check only areas where a water leak is suspected to have occurred, leading to more efficient checks.

Sawa: What’s not so great in terms of business, though, is the idea of “covering your bases through operations.” In other words, it’s reliant on people. Even if they are professionals, there’s a non-zero risk that they’ll make a mistake. That’s why we need to leverage technologies effectively. Data collected from sensors can be immediately used as electronic data and can be combined with other data in Lumada, enabling various analyses. That’s another aspect that really makes the service shine. Is it easy to convince customers to get on board with these types of new initiatives?

Ishii: Compared to other industries, the water business involves fewer parties, so it’s easier to build a DX*3 platform. That being said, to convince customers to use our new service, we first need them to experience its efficacy. I can confidently say that our service doesn’t lose out to any of the water-leak detection services offered by other companies.

Overview of the water-leak detection system

―What initiatives are underway in terms of businesses to provide clean environments?

Ishii: Against the backdrop of environmental issues, efforts to achieve carbon neutrality—for example, by using renewable or hydrogen-based energy—have accelerated over the past few years. Specifically with regard to hydrogen, we have been working with business partners to develop and verify hybrid power plants. These plants use surplus power derived from renewable energy to produce hydrogen fuel, which is then co-combusted with more traditional fuels. We are already working with several business partners such as Tomiya City in Miyagi Prefecture, Miyagi Coop in Sendai City, and Marubeni. In Tomiya City, we have already verified a diesel-engine power generator that runs on a mix of waste cooking oil and hydrogen fuel.

Sawa: What stands in the way of a complete switchover from fossil fuel to hydrogen fuel?

Ishii: Right now, cost poses a big obstacle. Once the technology spreads, prices will decrease as a result of mass production. As society’s demand for eco-friendly energy gains momentum and consumer behavior changes, the mindsets of energy providers will change as well.

Another problem with renewable energy is that the amount of electric power that can be supplied is not stable. Of course, that means that the amount of surplus power fluctuates and, consequently, so does the amount of hydrogen we can produce. Furthermore, because hydrogen is high voltage, you need special qualifications to transport it. In general, when it comes to transport, there are various extra steps that must be taken in terms of both safety and economic efficiency. Currently, people are researching and developing ways to store and transport hydrogen, for example, by converting it into ammonia or some other substance, but it seems there are still quite a few challenges ahead of us.

That being said, we’ve been working with an external business partner to verify the distribution of hydrogen by using cassettes of hydrogen storage alloys. With this method, we store hydrogen in metals and later recover it through heating and depressurization. Hydrogen storage alloys are non-hazardous, and it takes less than one megapascal of pressure to store hydrogen in or recover it from a hydrogen storage alloy. This method would allow us to produce hydrogen in an economical way by effectively using surplus power from renewable energy, waste cooking oil, and even food waste, which until now we’ve only been able to use as fertilizer. We’d also be able to transport that hydrogen in a safe, secure, and convenient way.

Sawa: Time and space are two things that are beyond our power to change. We can shorten neither time nor distance in a real sense. But technology achieves that in a virtual sense. However, as was made evident by the tanker grounding in the Suez Canal, reducing time and distance through the use of existing technologies is no longer enough. We need to build circular economies that can run locally or in isolation when the situation demands it.

Ishii: In Japan, too, regional depopulation coupled with a shrinking population has become a serious problem. In terms of managing and maintaining all of Japan on a single grid, we’ve already reached the limit. As you said, we need to create technologies that people can use even when they are cut off from the grid, and create ecosystems of local production for local consumption. I think the hydrogen value chain we’re working on lends itself to achieving that end. With this kind of technology, we’d be able to do things like transport hydrogen to developing countries lacking infrastructure networks and to use hydrogen in the event of a disaster.

―How does Hitachi plan to create a sustainable society through DX using Lumada?

Ishii: First, for water, we will create a DX platform that enables the use of operational data and inspection data, with the ultimate goal being to build a system that operates without any human intervention. Then, we want to expand that to other fields, such as roads, rivers, and disaster prevention. If we can do that, we’ll be able to collect various types of data for each municipality (such as a city, town, or village) on the platform we provide.

Looking beyond that, we will use data to promote circular economies, including the circulation of resources. This refers to, for example, disassembling household appliances, sorting their parts, and recycling raw materials, all the while recovering deleterious substances like fluorocarbons. Another example is extracting, from MRI machines, precious rare-earth magnets, which can then be reused in other products. We also hope to continue working with other Group companies of the Water & Environment BU, with other Hitachi BUs, and with external business partners to expand the circulation of resources on a larger scale.

With respect to the water business, under normal circumstances, there’s already a lot we can do in the way of full and partial automation. But when a disaster or some other sudden, unpredictable event occurs, we always end up relying on human judgment. How we clear this last hurdle is something to look into going forward. Of course, if we just replace human judgment with AI, we run into another problem, namely, that society might find it hard to swallow.

Sawa: We’re at a point where we can no longer put off addressing the issues of low birthrates and an aging population, so we need to keep automating everything and anything that can be automated. That would free people up to pursue more creative endeavors. We need to shift to that kind of perspective.

Ishii: Across all industries, pools of experienced workers are aging and shrinking, and so we need a way to pass on their knowledge and expertise to younger workers. I think, putting that knowledge into some kind of system is a surefire way to hand down information.

Sawa: Some people hesitate to use AI, claiming its inner workings are like a black box, but there’s really no need to understand the technology itself. Rather, it’s important to know why the technology is necessary. In the end, AI is just something to make people’s lives easier. It’s just code that someone wrote to enrich our lives, much like music.

Creating societies with circular economies by building local infrastructure,

starting with OT for water and the environment

Ishii: Speaking of AI, we’ve started a customer co-creation project called “Harbor AI Terminal,” which supports the business processes of terminal operators, specifically, the entire chain of processes from the unloading of containers from arriving ships to the yard, until the handover of such containers to a land transport company. Finding the container you need from among hundreds of stacked containers, moving aside any containers on top of it, and then handing it over to the transport company—this isn’t an easy task. The time from when a truck enters the terminal until it leaves the terminal, including the time it takes to load containers, is referred to as the truck turnaround time. Finding ways to shorten this indicator of task efficiency is a challenge that terminal operators face. Leveraging our past work in AI development, we’re now working on a project that will use AI to stack containers efficiently based on an analysis of complex conditions, and to detect scratches, holes, and other defects in containers based on image analysis.

Sawa: AI is perfect for this field. Using AI can lead not only to dramatically better efficiency but also to fewer oversights.

Ishii: But if you don’t have firsthand experience, an attempt to address this kind of issue will simply end as a pie in the sky. In that respect, what makes Hitachi unique is our involvement not only in IT but also in OT, where we both manufacture products such as control panels and water treatment equipment and operate those products for customers. To put it another way, our strength lies in our experience in combining and implementing OT, IT, and products.

Sawa: What made me decide to join Hitachi was the breadth of its assets and the appeal of helping create a sustainable society by combining those assets. There aren’t that many companies seriously engaged in both OT and IT. That gives Hitachi a real edge over its competitors.

Ishii: When it comes to Lumada, the integration of OT knowledge is also a crucial point. We’re accumulating knowledge while verifying it through customer co-creation projects. Going forward, I hope to wield this and other strengths to our advantage, further differentiating Hitachi and ensuring the growth of our water- and environment-related businesses.