Dialogue with the Chief Lumada Business Officer

2022-06-27

With its core technologies for observation, measurement, and analysis, and products that, for many years, have claimed global top shares in markets related to semiconductor inspection equipment and biochemical autoanalysis and immunization inspection equipment, Hitachi High-Tech has leveraged its state-of-the-art optical technologies to expand business to various fields such as medical care and materials development. Here, Hitachi High-Tech Chief Lumada Business Officer Hidetoshi Miura and Lumada Innovation Evangelist Madoka Sawa discuss, among other things, the direction of global businesses cultivated by Hitachi High-Tech as a specialized trading company with advanced technological capabilities, digital transformation initiatives that use Lumada, and actual cases where AI was used to support smart factories and the Hitachi Group.

―Please tell us about Hitachi High-Tech’s beginnings.

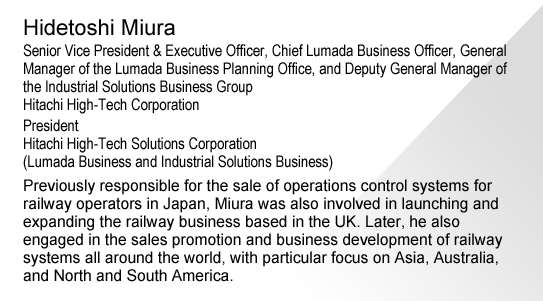

Miura: Hitachi High-Tech formed in 2001 when a unit under Hitachi, Ltd., that developed and manufactured cutting-edge electron-beam and optical technologies—specifically, technologies for semiconductor manufacturing equipment and for analysis and measurement equipment—merged with the trading company that sold that equipment. Having acquired the functions of the trading company, what sets us apart is our strong client-facing capabilities on a global scale. Currently, we have offices in 25 countries and regions outside of Japan that engage in community-based business.

Sawa: Actually having a global network is a huge advantage. I imagine that a development and manufacturing unit and a trading company are fundamentally different, right down to their DNA, but were the two sides able to develop synergy right from the start?

Miura: I heard there were some rough patches in the beginning, but now the two sides collaborate to bring out various synergies. Each side has a lot of people with real, first-person connections to the community they are in. That gives us a huge advantage.

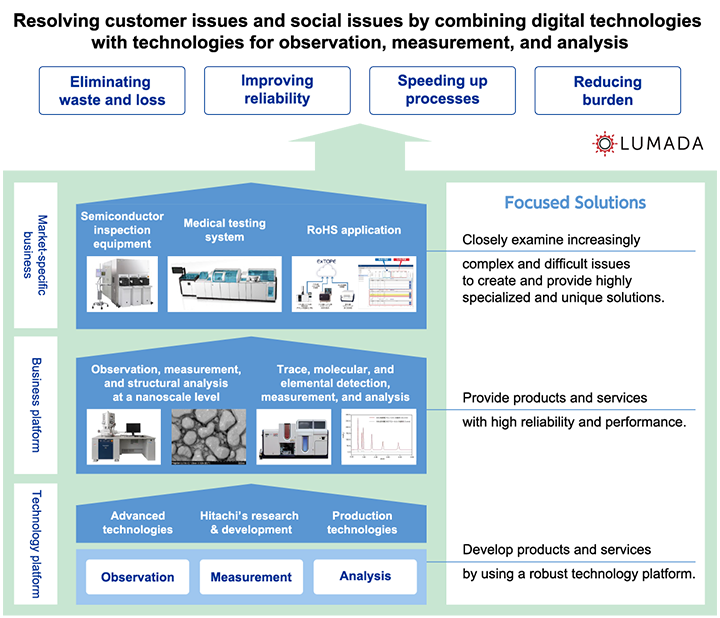

Sawa: I like how you referred to Hitachi High-Tech’s technologies in simple terms as “technologies for observation, measurement, and analysis,” but specifically, what kinds of technologies are we talking about here?

Miura: Our core technologies include technologies that use optics to measure the characteristics of various materials, and electron microscopes and other technologies for observing molecular structure at a nanoscale level far exceeding the cognitive abilities of humans. In a sense, you could say these technologies are the “eyes of science.” Regardless of how the world changes in the future, there will always be a need for these technologies, so I think it’s really important that we keep polishing and honing them.

Resolving issues by combining digital technologies with technologies for observation, measurement, and analysis

Miura: In order to connect our cutting-edge “eyes of science” to society, digital technologies are essential. In recent years, we’ve also been involved in leading-edge manufacturing and production driven by digital technologies and culminating in the smart factory Naka-Marine Site. Located in Hitachinaka in Ibaraki Prefecture, this state-of-the-art factory uses IoT and went into operation in March of 2021. There, we design, develop, and manufacture semiconductor manufacturing and analysis equipment, and look for optimal solutions by linking data throughout the entire value chain, from design, prototyping, and verification to manufacturing, delivery, and maintenance. Furthermore, to make it an eco-friendly site, we’ve been working to eliminate the factory’s CO2 emissions by using renewable energy and installing solar panels. We also minimize its electricity consumption by monitoring electricity use in real time.

Speaking of eco-friendliness, we’ve been really focusing on managing the lifecycles of lithium-ion batteries. Our work with the automotive and railway industries led us to the belief that the recycling of lithium-ion batteries would eventually become a critical issue, so a few years ago, we launched a business to tackle that issue. Going forward, initiatives that conform to Europe’s environmental regulations will also become mandatory. To that end, we’ve developed a fast diagnostic system that assesses aging and deterioration in lithium-ion batteries. By utilizing the data, we can track the condition of lithium-ion batteries, facilitating their recycle and reuse.

Turning our attention to the manufacture of lithium-ion batteries, the contamination of batteries by metal fragments or other substances can pose a fire hazard. As such, the detection of such contaminants is extremely important. Hitachi High-Tech’s X-ray equipment plays an active role in detecting foreign substances on manufacturing lines. In other words, we have a hand in developing useful technologies for each and every link in the value chain for lithium-ion batteries, from their manufacture to their reuse. That’s why we can get an overarching view of the industry as a whole and use that perspective to uncover new issues.

Sawa: I see. Those issues become apparent through your collaborative work with customers. You also have a site in Portland in the US, right?

Miura: Yes. To establish robust, local support systems and resolve real issues with speed, we need to carry out development near our customers. As part of that strategy, we established the Hitachi Center of Excellence in Portland as a new site for semiconductor engineering. Located in Hillsboro, Oregon, the center has become a setting for co-creation.

Sawa: So, even with the local community, everyone shares and is loosely connected by the same vision, almost like a corporate entity. In a real sense, this embodies the concept of community building, which has been gaining prominence, and of organizations in the modern age.

Due to COVID-19 restrictions, this dialogue was held virtually.

Sawa: What about Lumada? Are you also using it and sharing information on a global level?

Miura: Yes, we are. Using Lumada as a keyword, we’ve been able to connect to other groups across organizational boundaries, and it’s also a place where we can share both success stories and less-than-successful cases. Lumada is not just an IoT platform for getting data and tools; it’s full of the expertise and efforts of Hitachi Group employees. This wealth of expertise is provided in the form of “customer cases,” which is what we call actual cases of co-creation with customers. As a stage for consensus building, it’d be more accurate to refer to Lumada as a field rather than an IoT platform.

Sawa: I like to think of Lumada as the spirit or banner that brings people together to discuss shared interests. It is truly the setting for co-creation.

Miura: Nowadays, rather than being based in Japan, we’re seeing an increase in communities spanning various regions, for example, between Asia and the US or between the US and Europe. Under the banner of Lumada, networks are being revitalized in a wonderful way.

Sawa: The deciding factors as to whether a community lasts, are whether consensus can be reached and whether the community can take root. If these two things can be accomplished, more people will feel comfortable taking part in the community. Lumada is basically a mechanism for accomplishing that.

Miura: In FY 2021, we provided orientation sessions about Lumada for employees at our overseas sites and created English pages of our intranet site. By deepening people’s understanding of Lumada, we as a company are providing more opportunities for our employees to make bold moves with respect to digital businesses. Naturally, people in each country and region have their own interpretations, and I think each community should be able to interpret and apply Lumada as they see fit. To that end, we’re always striving to be more sensitive and receptive to the market needs and the unique business practices and rules of each country.

―How are the technologies and initiatives of Hitachi High-Tech used by or applied to the Hitachi Group as a whole?

Miura: In a sense, you could say that Hitachi High-Tech is analogous to Lumada itself. By which I mean, the Hitachi Group, as a whole, handles a wide range of businesses for different customers in different industries and with all different products. In the midst of that, Hitachi High-Tech has teamed up with various business units and become a sort of hub, navigating freely among the multitude of groups and connecting different people.

We also possess a diverse arsenal of advanced technologies that facilitate carbon neutrality—which all of the Hitachi Group is working toward—as well as a broad spectrum of other businesses. One of these technologies is materials informatics, whereby we apply vast amounts of materials data and AI (such as machine learning) to the development of new materials and medical and pharmaceutical products. For example, at Hitachi High-Tech Solutions, where I serve as company president, we’ve independently developed a system called “Compound Discovery AI.” This AI is specialized to find chemical compounds and has already proven itself useful in resolving issues faced by our customers. By using this system, we are able to dramatically cut down the time needed to search for chemical compounds. You could say we are pushing the limits of time.

Speaking of which, we have a long history of reducing the time needed to get blood test results with respect to our biochemical autoanalysis equipment. This equipment has been developed over the course of 50 years, starting from when we were just a unit under Hitachi, Ltd. If we continue to pursue this, one day it might even be possible for people to monitor their own blood in real time and change their behavior accordingly, leading to better healthcare.

Sawa: I always say that the essence of digital technologies is their ability to virtually release us from the absolute and immutable restrictions of time and space. And Hitachi High-Tech is right on the frontline of that action. One by one, the futuristic technologies portrayed in sci-fi movies are becoming a reality. It really makes me curious about what the future will bring.

At the same time, real experiences are still indispensable for people’s happiness. I think, how we use technology to give people real experiences will be our greatest task.

Miura: I agree. In the future, I think the way that a business enriches the time and space we inhabit and provides real experiences will be key in determining how it fares against the competition.

As I mentioned earlier, no matter what changes lie ahead of us, there will always be widespread demand for Hitachi High-Tech’s advanced technologies. That’s our true identity. Going forward, we will keep enhancing our state-of-the-art technologies and accelerating digital transformation through Lumada, in the hope of improving the quality of life and wellbeing of people all around the world.

Location: Shinko-cho, Hitachinaka City, Ibaraki Prefecture

Lot size: Approximately 125,000 m²

Floor area: Approximately 50,000 m²

Structure: 6-story steel building

Overhead investment: Approximately 30.0 billion yen

Description: With an eye on market trends—specifically, the growing demand for tablets and smartphones, as well as for semiconductor devices for electric, autonomous, and other types of vehicles—Hitachi High-Tech built this new factory as a development environment that would enhance its production capabilities and bring forth a diverse product lineup.

now handles the design, development, and manufacture of Hitachi High-Tech’s main products, centered on semiconductor manufacturing and analysis equipment.