Featured customer case

Lumada customer case code: UC-01293S

Making plans that use the Supply Chain Optimization Service to optimize the handling of fluctuations in demand

2022-11-09

Suppliers need to quickly identify fluctuations in demand caused by factors such as the diversification of consumer needs, and need to supply their products appropriately. This article looks at customer cases for optimizing the supply chain while maintaining its overall resilience, even under the apparently conflicting conditions of reviewing excess inventory and optimizing distribution sites based on the reviewed inventory.

This service utilizes data, from procurement to sales, to automatically make highly accurate plans tailored to the customer’s business operations.

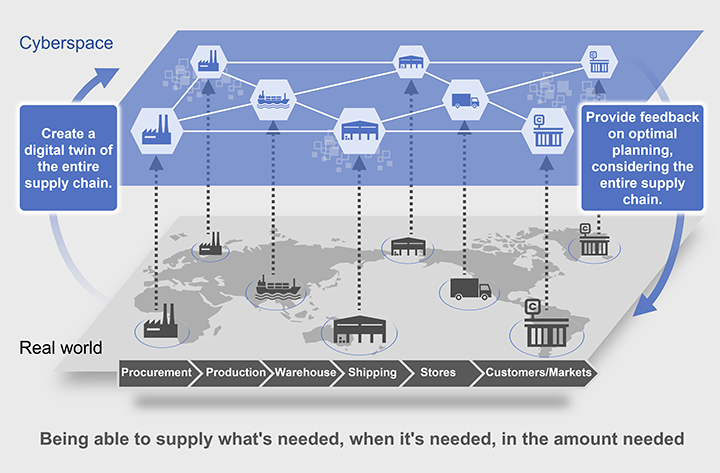

A digital twin is constructed in cyberspace, and real-world data is linked to enable estimates and predictions of what is likely to happen in the future. By conducting multiple trials without worrying about the impact on business operations, the customer can make optimal plans for their entire supply chain and provide feedback in the real world.

Co-create with Lumada! Utilizing business operation data to optimize supply chains

Diversified work styles and values are changing the demand for products. In order to achieve supply that responds to changes, we need to accurately know how much of what product is required when and where. However, it is difficult to manually obtain such data and to manually optimize the entire supply chain.

Demand for products is constantly fluctuating due to factors such as changing consumer needs. Various matters must be considered in order to ensure profitability despite fluctuations of varying sizes. These include, for example, reducing costs by closely tracking product sales to avoid excessive inventory.

One way to effectively reduce costs is to consolidate distribution sites. In order to consolidate sites while meeting adequacy rates relative to demand, we need to accurately track the status of inventory ready for timely shipment and inventory lying unshipped. In addition, we need to consider optimization of the entire supply chain, including reviewing fixed production plans and unexpected shipments.

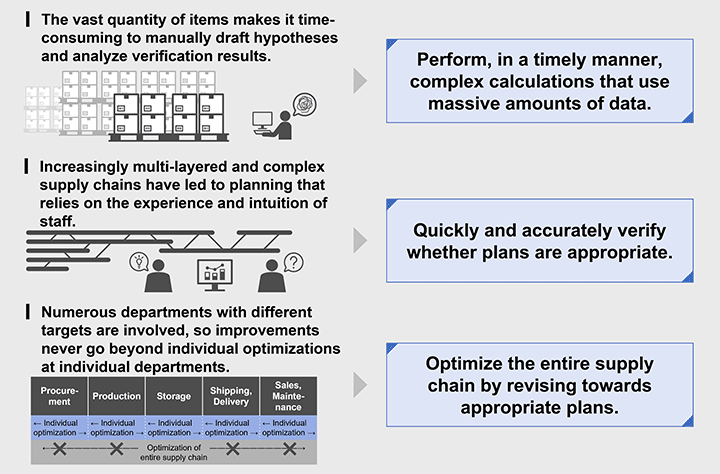

Even if you understand what should be done and want to balance supply and demand, manage inventory, and verify shipping costs in an appropriate and timely manner, the following problems arise due to factors such as the vast quantity of items, increasingly multi-layered and complex supply chains, and the conflicting goals of the departments involved:

An effective way to optimize inventory and reduce costs is to visualize the adequacy rates relative to demand. Hitachi’s Supply Chain Optimization Service uses the following features to find measures for optimizing the entire supply chain:

Specifically, this service checks the status of incoming and outgoing shipments based on daily operational data from distribution sites and then calculates the inventory quantity and inventory quantity forecasts. By also analyzing warehouse capacity, this service allows users to consider the optimization of distribution sites to match their appropriate inventory, thus reducing costs.

Having found the appropriate inventory, users can review production and shipping plans to reduce excess inventory and irregular shipments, leading to optimization of the entire supply chain.

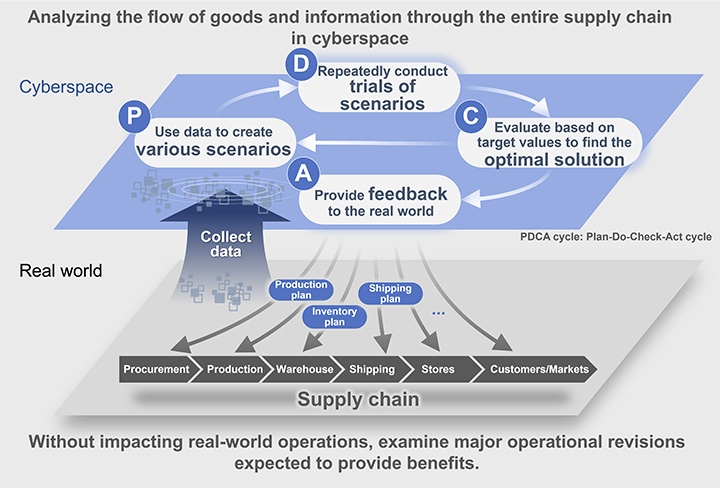

Data collected in the real world is utilized to make a digital twin, thereby creating a close copy of the real world in cyberspace. Analyzing the flow of goods or information throughout the supply chain through this technology allows the user to make estimates and predictions of the future of the real world.

Because scenario trials in cyberspace do not impact real-world operations, various scenarios can be created and trialed repeatedly. Evaluations can be made based on target values and the optimal solutions obtained can be provided as feedback in the real world, thus allowing users to consider major revisions of business operations that were previously impossible.

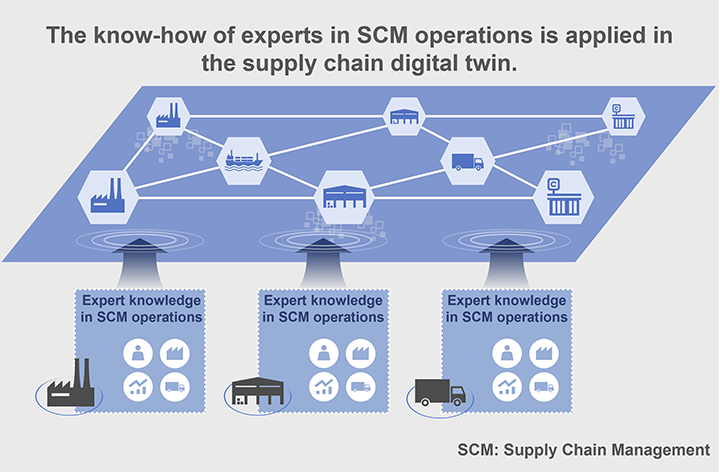

To make a highly effective business operation review plan with highly accurate SCM (supply chain management), all the information collected in the real world must be reflected in the digital twin.

The digital twins reproduced with the Supply Chain Optimization Service include not only physical sites such as factories and warehouses, but also the SCM workers (people) who are in charge of procurement, production planning, shipping, and other operations at each site. Since the SCM operations themselves, which are filled with knowledge, are reproduced, complex scenarios can be tried and evaluated on the digital twin, which is a close copy of the real world.

In addition, SCM operations that are performed by experts only at specific sites can be applied to and positioned at all sites in the digital twin, allowing for an ideal operational plan to be made with a perspective encompassing the entire supply chain. This ensures uniformity in the accuracy of operations, improves quality, and eliminates over-reliance on particular individuals.

Appropriate inventory levels to supply what’s needed, when it’s needed, in the amount needed

This service collects and utilizes a variety of data generated on a daily basis to automatically make plans that optimize the entire supply chain.

The Supply Chain Optimization Service creates a digital twin of the entire supply chain by linking in cyberspace the data generated on a daily basis from real-world procurement, production, warehouses, shipping, stores, customers, and markets. By trying out scenarios such as different fluctuations in demand or different inventory and production statuses, the service enables estimates and predictions related to the flow of people, goods, and information.

This enables customers to make optimal plans covering all of their business operations while responding immediately to fluctuations in demand. This helps them achieve optimum inventory levels that can supply what’s needed, when it’s needed, in the amount needed.

Departments sometimes have conflicting target values: for example, one department might want to practically eliminate product shortages to prevent the loss of sales opportunities, while another department might want to use appropriate inventory levels to reduce losses due to disposal of excessive product inventory and to reduce storage costs. Even in such a situation, however, this service quickly provides highly accurate plans that contribute to continuous improvement of the supply chain and to solutions for management issues.

This section describes an example of a clothing and accessory retail company that investigated implementing the Supply Chain Optimization Service. The verification investigation confirmed that the service reduced inventory and site management costs.

The market for clothing and accessories is shrinking due to factors such as a declining workforce caused by the falling birthrate and aging population. This major retail company had excessive inventory caused mainly by intuition-based ordering. Because the company realized they needed to review this situation, they used a year’s worth of data on incoming and outgoing products, inventory, and warehouse capacity to automatically calculate an optimal supply plan using the Supply Chain Optimization Service. This verification confirmed the following benefits:

In addition, the verification process confirmed that optimizing inventory would allow the retailer to reduce their distribution sites by one and cut their site management costs by over 10%.

The Supply Chain Optimization Service is applicable to all industries and business operations that have inventories of raw materials, products, etc. From the perspective of total optimization across departments, this service eliminates fruitless efforts that occur in each department and uses a consistent approach to achieve productivity improvements and cost reductions.

In addition to changes in consumer behavior due to diversifying lifestyles, there are also factors such as infectious disease pandemics, sharp exchange rate fluctuations, and tense international situations, which are having an increasingly apparent impact on supply chain operations.

Moving forward, Hitachi will improve the functionality as well as expand the options for our Supply Chain Optimization Service in order to help a wide range of customers optimize and maintain the resilience of their entire supply chains. In addition to solving our customers’ management issues, we will also contribute to achieving SDGs by reducing losses due to disposal of excessive product inventory and thereby reducing the burden on the environment.

For details on our solutions, see the following webpages.

This service utilizes data, from procurement to sales, to automatically make highly accurate plans tailored to the customer’s business operations.

A digital twin is constructed in cyberspace, and real-world data is linked to enable estimates and predictions of what is likely to happen in the future. By conducting multiple trials without worrying about the impact on business operations, the customer can make optimal plans for their entire supply chain and provide feedback in the real world.