Featured customer case

Lumada customer case code: UC-01507S

Automatic Ordering Service Based on Demand Forecasting

2021-09-30

Today, consumer needs are diversifying, and trends are changing rapidly. Retailers are required to forecast demand with high accuracy. In Hitachi’s Automatic Ordering Service Based on Demand Forecasting, the system forecasts demand and calculates the optimal quantities. You can optimize the setting of standards and operation while promoting the automation of ordering operations, which tend to depend on the skills of individuals.

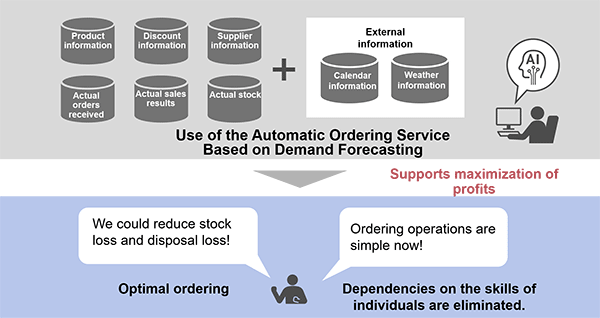

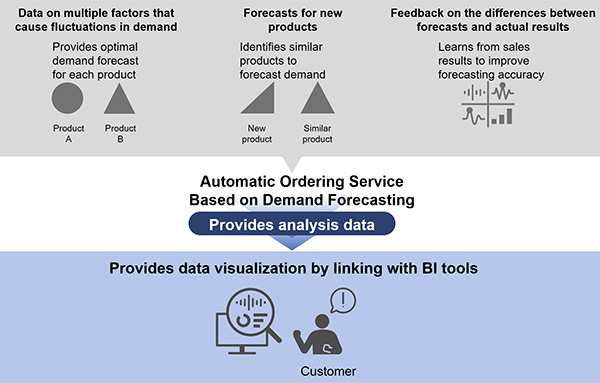

The system builds a forecasting model by appropriately combining the data for multiple factors that cause fluctuations in demand. Such data includes product-specific data and external data such as data on the weather and seasons for each store. Based on this model, the system forecasts the demand for products to determine the optimal order quantity, and then automatically places the order. In addition, the system creates reports to analyze the data. The service can reduce the burden of on-site operations, eliminate dependencies on the skills of individuals, and reduce inventory loss, thereby helping to maximize profits.

Collaborative creation with Lumada! Using a system for forecasting daily demand

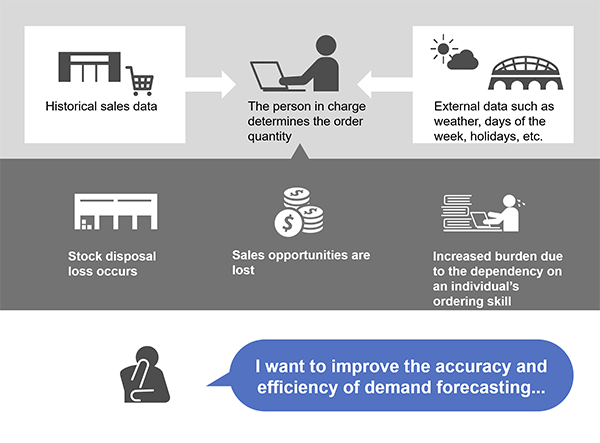

In retail businesses such as food supermarkets, personnel in charge at each store spend a lot of time every day in product-ordering operations.

Each store must decide the order quantity by considering complex conditions such as past quantities sold, the quantities that had to be disposed of, weather conditions, and event information for each product.

If demand forecasting is difficult and the forecasting accuracy is low, the following problems might occur:

Furthermore, since demand forecasting depends on the experience and know-how of the personnel in charge, the ordering operations become dependent on the skills of individuals. This can lead to the problem of increasing burdens on specific personnel.

If you can calculate appropriate inventory levels and highly accurate order quantities, you can streamline ordering operations and optimize the inventory. In addition, demand forecasting by the system enables you to reduce the on-site burden by reducing the work time of the personnel in charge of ordering operations, and by eliminating dependencies on the skills of personnel in charge of ordering operations.

One of Lumada’s solutions, the Automatic Ordering Service Based on Demand Forecasting, collects sales history data (quantities sold, quantities ordered, quantities disposed, promotion events, etc. for each product) and external data (weather, days of the week, holidays, etc.) accumulated in the ordering system. Based on this large amount of data, the system forecasts demand, automatically calculates appropriate inventory levels, and proposes appropriate order quantities.

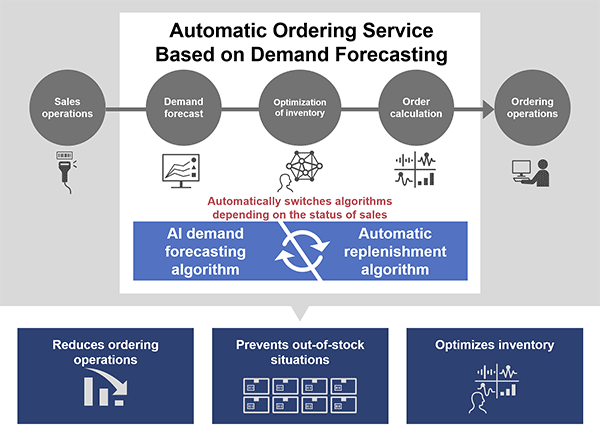

Introducing the Automatic Ordering Service Based on Demand Forecasting can provide the following benefits:

Achieving these benefits will help you maximize profits.

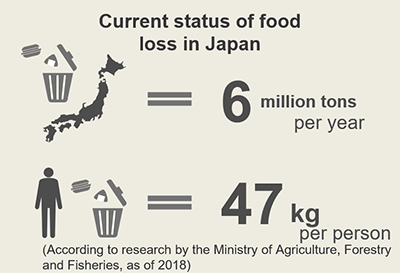

Food retailing faces the problem of excessive ordering, which is practiced in order to prevent lost sales opportunities.

To address this kind of social issue, Hitachi provides the Automatic Ordering Service Based on Demand Forecasting to food supermarkets. We aim to contribute to the reduction of food loss by preventing overstocking of food.

Food loss refers to food that is discarded even though it is still edible. In Japan, about 6 million tons, or 47 kilograms per person, of food is lost annually. Of this amount, business-related food loss amounts to 3.24 million tons (according to research by the Ministry of Agriculture, Forestry and Fisheries, as of 2018).

Goal 12 of the SDGs (Sustainable Development Goals), “Responsible consumption and production,” calls for a significant reduction in food loss by 2030.

If each of us consumes food carefully without wasting it while keeping this goal in mind, we can solve the following problems caused by a large amount of food loss.

Leveraging historical sales data

In the Automatic Ordering Service Based on Demand Forecasting, the system forecasts daily demand repeatedly on a daily basis. It determines and proposes the optimal quantities to order.

The Automatic Ordering Service Based on Demand Forecasting has the following features:

The service also provides data for analysis, such as trends in quantities of orders received and placed and the amount of inventory, and demand forecasts. In addition, use of the service by linking with BI (Business Intelligence) tools enables easy data visualization.

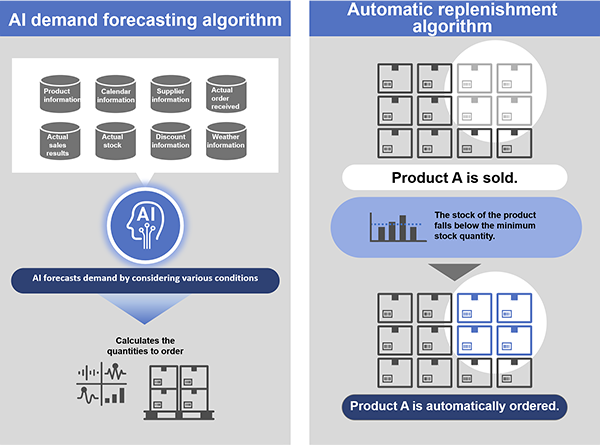

The Automatic Ordering Service Based on Demand Forecasting uses two types of algorithms: an AI demand forecasting algorithm and an automatic replenishment algorithm. The AI demand forecasting algorithm takes into account conditions, such as the characteristics of the products handled, to forecast demand and calculate order quantities. The automatic replenishment algorithm sets thresholds for sales frequency and inventory quantities, and automatically orders products when those values are exceeded.

The Automatic Ordering Service Based on Demand Forecasting proposes more appropriate ordering by automatically switching between these two algorithms in a timely manner. Ordering and inventory management can be automated even if there is a mix of products with high and low inventory turnover ratio in a store, or if there are products whose demand changes with the season or weather.

Inventory turnover ratio is a measure that shows how many times the stock is replaced in a certain period of time. The higher the ratio, the faster the cycle is for a product shipped in and shipped out of the warehouse, which indicates that the product is selling well. On the other hand, a lower ratio indicates that a product remained in the warehouse for a long period of time.

By understanding the inventory turnover ratio, you can visualize the turnover of your stock, and concretely understand the pace of product sales and which products are sold in a certain period of time. From the inventory turnover ratio, you can also understand the consumer needs. Using the inventory turnover ratio, you can take measures such as preventing popular products that demonstrate a high inventory turnover ratio from going out of stock, and curb the ordering of products that demonstrate a low inventory turnover ratio. Such steps prevent lost sales opportunities and reduce unnecessary costs caused by disposal losses from excessive inventory.

Today, consumer needs are diversifying, and trends are changing rapidly. For retailers, ordering and inventory control are critical operations that directly affect store sales, profits, and operational efficiency. Hitachi will continue to expand the functions of the Automatic Ordering Service Based on Demand Forecasting to deploy the service at retailers such as clothing stores and supermarkets, thereby contributing to the enhancement of social, environmental, and economic value.

Furthermore, Hitachi will also build forecasting models for the Automatic Ordering Service Based on Demand Forecasting according to the requirements of customers. This will enable us to provide solutions for a wide range of industries, including wholesale, manufacturing, and equipment services, as well as retail.

For more information on our solutions, see the following:

The system builds a forecasting model by appropriately combining the data for multiple factors that cause fluctuations in demand. Such data includes product-specific data and external data such as data on the weather and seasons for each store. Based on this model, the system forecasts the demand for products to determine the optimal order quantity, and then automatically places the order. In addition, the system creates reports to analyze the data. The service can reduce the burden of on-site operations, eliminate dependencies on the skills of individuals, and reduce inventory loss, thereby helping to maximize profits.