Handy method for quantitative evaluation of microstructures of material samples fabricated in manufacturing facilities or laboratories

March 26, 2019

Hitachi, Ltd. today announced an efficient material development method to predict material properties through features extracted from electron microscope images of material samples such as alloys by applying machine learning. By analyzing microscope images of chromium-based alloy, Vickers hardness, a material property index, was successfully predicted with a margin of error of ten percent or less. This method enables simple and quantitative prediction of material properties from electron microscope images in development of materials and material manufacturing processes.

Towards efficient material development, materials informatics combining large-scale simulation and informatics to identify promising materials or compositions mainly in the early stages of material development has been attracting attention. Meanwhile, in the development of material processes, experimental sample fabrication and evaluation are essential as complete simulation to predict complex systems from an atomic scale to a manufacturing scale is difficult. Efficient material development through systematic sample fabrication and evaluation has been expected, but criteria cannot be determined quantitatively due to the absence of a model linking material fabrication processes and property evaluation results. Consequently, formulas for next-sample fabrication derived from property evaluation results are dependent on the knowledge and experience of material development engineers.

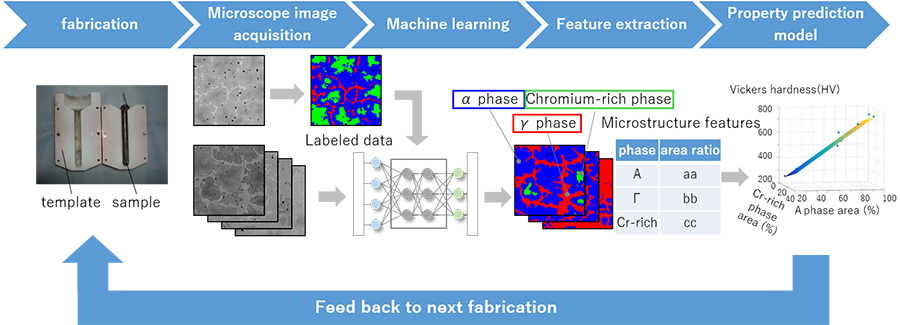

Hitachi recognized that microstructures of materials are an intermediate factor between material formulas and properties, and addressed simple and quantitative evaluation of microstructures of material samples. Specifically, we extracted features from electron microscope images of material samples by applying machine learning, and created a prediction model that links features with material properties using regression analysis(1). This result indicates that material properties can be predicted from electron microscope images. By applying this method, a model which links manufacturing formulas with material properties can be created through microstructure features. Hitachi will apply this method to various materials and optimize material compositions and processes to contribute to development of materials for a sustainable society.

Flow of material development using microstructure analysis

A part of this technology was presented at 2018 Materials Research Society Fall Meeting & Exhibit held from Nov. 25 to 30, 2018 at the Hynes Convention Center in Boston.

An electron microscope is a useful tool for observation of microstructures of material samples, but one issue in using them is that images are formed based on multiple physical phenomena, which sometimes results in unnecessary information included in the images. In this study, we observed a chromium-based duplex alloy(2) using a detector with an optimized acceptance angle installed in the electron microscope to suppress unnecessary information (crystal orientation) and enhance composition information of crystals, which is an important index for material evaluation.

To obtain features for quantitative characterization of microstructures correlating with material properties from electron microscope images described above, we applied a machine-learning technology. We built a classifier to distinguish phases (regions with identical crystal structures) inside the images by using several images. By using the classifier, microstructure features such as the surface area of a phase are extracted from a large number of images. Moreover, among the microstructure features, features that correlate strongly with material properties are selected through application of statistical approaches.

By selecting two features, i.e. area ratio of α phase(3) and area ratio of chromium-rich regions in α phase, we confirmed that a material property index called Vickers hardness(4) can be predicted with a margin error of ten percent or less. This result indicates that material properties can be predicted efficiently from electron microscope images obtained in a short time.

For more information, use the enquiry form below to contact the Research & Development Group, Hitachi, Ltd. Please make sure to include the title of the article.