Energy & Equipment Management Service enables a corporation to comprehensively manage energy data and equipment across multiple business facilities of any type and scale, including offices, factories, shops, hospitals and data centers, and thus save energy, improve work efficiency and implement a BCP. Hitachi collaborates with a large number of business partners in countries and regions around the world. Taking advantage of its extensive installation experience and expertise for xEMS and other equipment, Hitachi has positioned xEMS as an energy & equipment management service for consumers, and promotes our Service based on the concept of a “service mall.”

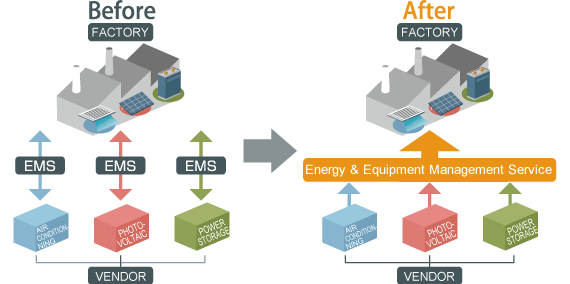

The bulk of xEMS products provided by equipment manufacturers such as Hitachi have thus far focused on controlling energy consumption for specific business types, sizes, equipment and facilities. For this reason, customers have traditionally had to install different products depending on their purpose. However, our service mall concept enables a corporation to control energy consumption across multiple business facilities regardless of type or scale. In addition, permissions to access data and applications can be issued not only to customers but also to equipment manufacturers and research or consultancy firms. This visibility of support and data facilitates timely online responses, helps users to resolve problems, and aids companies in preparing well-planned, effective, energy-saving measures and upgrade equipment.

Our Service allows customers to select one of three system models in accordance with their operational requirements and management scale.

(*) If operating outside of Japan.

Our Service defines a sustainable work control process that is classified into the four categories below, and services are provided to users in an easily understandable manner according to those categories.

Air conditioners account for a large part of energy consumption in offices while manufacturing equipment accounts for a large part in factories. The FEMS function of our Service enables users to fetch production plans from the production control system, simulate peak energy consumption by changing production shifts and provide useful guidance for equalizing energy consumption (optional function). Thus, customers can obtain additional value by linking our Service with other services such as environmental control and equipment register management.

FEMS: Factory Energy Management System

Our Service will gradually incorporate support for de facto standard communication specifications, which are widely used across various industries and regions. In Japan, our Service will support a range of standards including BACnet/IP, Modbus/TCP, major companies' PLC communication, as well as communication of major air conditioning manufacturers. With regard to requests for electricity-saving from power companies, we are looking into the possibility of adding support for OpenADR, when the standard becomes more popular in Japan. Overseas, we will assess communication standards used in Southeast Asia, Europe and U.S. and expand our range of support in coordination with local business partners.

BACnet/IP: Building Automation and Control Network/Internet Protocol

BP : Business Partner