Triumphing with Industrial AI

Our lives have been transformed by Artificial Intelligence in both visible and invisible ways. We’ve taken in stride new AI-enabled tools, like face-recognition software to unlock our smartphones. We enjoy sophisticated recommendations while shopping online or using our favorite streaming services. We may not even notice how curated our personalized news feeds have become.

While these consumer-facing AI applications have greatly enhanced convenience and personalization, Industrial AI, the unique application of AI in industrial domains, holds the potential to revolutionize many industries, such as manufacturing, energy, mining, and logistics. In this three-part blog series, we will explore the challenges and rewards of implementing Industrial AI.

The potential value in developing Industrial AI is estimated to be some ten to fifteen trillion dollars. About one-third of that would come from AI models and applications used in supply chain management and manufacturing operations. AI-based solutions combine data science, machine learning, and related technologies. If industrial organizations harness this kind of data-informed decision-making, they can enjoy more streamlined operations, greater safety and sustainability, and increased productivity and even profitability. Industrial AI will be the cognitive engine of the Fourth Industrial Revolution.

The growing impact of Industrial AI is reflected in the following areas:

- Manufacturing organizations seek to “do more with fewer resources”, and commonly look to digital technology as a solution as part of continuous improvement programs.

- Most manufacturers have teams dedicated to Industry 4.0 (“I4.0”) or “manufacturing digitization”; many have executive leaders responsible for this, including formalized “product owners”.

- IT organizations are frequently focused on building efficient and scalable platforms to support Industrial AI, rather than experimenting with proofs-of-concept.

- The technology eco-system is becoming ubiquitous: many software firms provide IIoT platforms, major cloud hyper-scalers have dedicated efforts around Industrial AI, and thousands of “.ai” boutique firms offer analytical expertise.

- Manufacturing engineers are exiting academia more technology-savvy and statistics-capable than ever before, ready and able to apply digital tools.

There’s enormous potential value in deploying Industrial AI. About 50-60% of companies have deployed AI so far, according to surveys, but due to technical challenges, they haven’t yet scaled it. Here are the three most crucial challenges businesses face:

Challenge #1. Lack of a compelling, business-aligned transformation roadmap

In many cases, digital initiatives are arranged by ideas of “digital maturity” which progress in a linear way, often from:

- Descriptive to Predictive to Prescriptive

- Connection to Visualization to Insight to Recommendation to Automation

Ideas of maturity are often driven by technical support capabilities, which might be out of alignment with business or operational problem-solving needs. The common refrain when presenting Industrial AI solutions to solve critical business or operational issues is, “We aren’t there yet.”

Also, IT-Operations communication channels and tools must be improved: Operations must recognize IT constraints and build these limitations into the feasibility side of Industrial AI project definitions. IT employees, for their part, must appreciate and fully understand the operational value proposition of the Industrial AI solution in order to appropriately prioritize.

Challenge #2: Multi-Disciplinary Technical Expertise Is Essential

It’s a complex challenge to apply AI to solve industrial issues and drive tangible business impact. Among other things, this requires domain expertise, the integration of new operational technology (OT), and the configuration of new digital infrastructure(s). Industrial AI applications also present technical challenges because they bring with them stringent requirements for worker safety, data privacy, and reliability. The data generated in industrial settings is usually quite complex and heterogeneous, which also complicates data management.

Challenge #3. It’s Complex to Map Business Needs to Technical Capabilities

Real-world businesses face a number of uncertainties, such as:

- Variability in customer demand

- Unexpected failure of equipment

- Fluctuations in environmental conditions

Industrial processes are usually complex and involve a number of interconnected sub-processes. Even well-defined business needs and objectives have nuances that need to be well-understood and factored into solution development.

Meanwhile, the portfolio of technologies and solutions available to the Industrial AI practitioner is vast, often novel or unproven, and rarely well-catalogued.

Aligning complex requirements to complex solutions, often under the watchful eye of a return-on-investment expectation, requires considerable leadership and proficiency.

What Can We Do?

There’s an “Industrial AI adoption bottleneck” at hand, as business architects compare what’s been done before to current problems manufacturers face.

We call on industry groups and industrial digital transformation leaders to think more broadly and deeply about Industrial AI taxonomies. A structured taxonomy for Industrial AI will accelerate solution realization and increase value delivered. Here are its benefits:

- A clearly articulated business value statement supports tying Industrial AI initiatives to outcomes.

- A common definition of use cases and solutions supports collaboration across factories or industries.

- A structured categorization scheme helps to match AI solutions with operational needs.

- A common language allows for Operations and AI experts to better work together.

Thanks to Hitachi’s expertise in both OT and IT, and our extensive experience helping our industrial customers on their DX journeys, we’ve built an Industrial AI roadmap. This includes a taxonomy of common problems faced by customers across different industries where AI could drive better business outcomes.

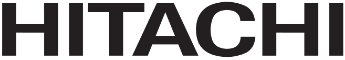

Our Hitachi Industrial AI taxonomy (described in Figure 1) proposes a structured and linear method of identifying, describing, and defining Industrial AI problems: from business outcomes to operational problems to analytical approaches. The framework is broad enough to be reused and reapplied. It’s also a tool to help communication between business, operations, and technologists.

Figure 1: Hitachi Industrial AI Taxonomy Framework

1. Organize by Operational Domain: The broadest categorization of problem sets aligned to typical operational organizations.

2. Define Operational Problem(s): A clear and concise problem statement is critical to align all parties. Identification of the desired operational outcome (KPI) and articulation of what needs to change in order for this outcome to be achieved is critical, and often omitted. This includes:

- KPI necessary to improve

- Decisions we’re looking to make

- Which lever to pull, based on the result

- Timeframe of decision-making: seconds, hours, days, or months

3. Define the Analytical Problem: A definition of how the problem should be solved, including key mathematical principles if necessary.

- Analytical Problem Type

- Analytical (Mathematical) Approach

4. Select from a Reserve of Possible Solutions: Products, Accelerators and Examples available to address the Industrial AI solution.

| Category | Quality Improvement |

| Primary KPI | First Pass Quality |

| Operational Question | Which setpoints or constraints to follow? |

| Controllable Lever | Production Control |

| Decision Type | Tactical (days – months) |

| Analytical Problem Type | Recommendation |

| Analytical Approach | Operating Envelope Recommendation |

Extensive experience has proven to us that our AI expertise can help develop advanced solutions to face any technical challenge which may crop up. To solve real-world, complex industrial problems, we need to draw on advancements in AI subfields such as deep learning and machine learning, statistics, operations research, and optimization. In our coming posts, we’ll showcase our innovative work in AI — and in the next post, we’ll address Dynamic Scheduling and Asset Management.

Stay tuned!

Authors:

David McKnight, Director of Digital Manufacturing Solutions, Hitachi Digital Services

Haiyan Wang, Principal Research Scientist and Manager, Hitachi America Ltd.