Unit 1 of the Shimane Nuclear Power Station operated by Chugoku Electric Power entered service in 1974. With Hitachi as the manufacturer, this was the first time a domestically produced nuclear reactor was constructed and delivered by a Japanese manufacturer. In 1989, Unit 2 entered operation and had been contributing to the supply of electricity in the region, but just as Unit 3 was about to enter service, the Great East Japan Earthquake struck in 2011. All operations were halted as a result.

The decision to decommission Unit 1 was made in 2015, and after undergoing construction work to implement safety measures to comply with new regulatory requirements, Unit 2 resumed operations in January 2025. Construction work to implement safety measures are currently being performed on Unit 3 ahead of its planned operational launch in fiscal 2030.

Yasumasa Matsui visited the interior of the building still under construction to take advantage of the period before Unit 3 is loaded with fuel (the process of placing nuclear fuel inside the nuclear reactor pressure vessel). He reports on scenes from the site, where there is a single-minded pursuit of safety and reliability in compliance with the new regulatory requirements.

“I've always wanted to visit this place, and finally I can see it in person,” remarks Matsui thoughtfully as he steps foot on the Shimane Nuclear Power Station.

The site of approximately 1.92 million square meters looking out over the Sea of Japan to the north of Kashima in Matsue City, Shimane Prefecture is situated at a ria-type coastal inlet, surrounded by mountains on three sides.

“After the Great East Japan Earthquake, I spent around a year traveling to all 54 nuclear power plants in Japan to see them with my own eyes. I even visited the Oma Nuclear Power Plant that is under construction in Aomori Prefecture. This was essentially personal fieldwork, not part of my job,” recounts Matsui. As he was unable to enter each site, he would check the location by looking at the buildings from outside the fence, visit offsite centers and PR facilities, actually drive a car to verify road conditions in the area, and think about resident evacuation routes and other aspects in the event of a large-scale disaster, as part of efforts to verify each power plant from the perspective of regular residents, he explained.

“During those travels, the hurdles were particularly high here at the Shimane Nuclear Power Station, because there is not a good view of the building from nearby roads. When I went to the top of a mountain and parted some thicket, I finally got a view of it. I probably looked quite suspicious to an outsider (laughs). So today, finally being able to enter the site, especially while it is still under construction, is something I have been looking forward to.”

Construction of Unit 1 of the Shimane Nuclear Power Station got underway in 1970 as Japan's fifth nuclear power plant, entering service in 1974. Unit 1 was the product of joint research between Chugoku Electric Power and Hitachi, Ltd., with the aim of domestically producing nuclear reactors that had previously relied on imports. This was the first boiling water reactor (BWR) to be developed and constructed in Japan. Later, with Unit 2 coming online in 1989, regional power needs were supported for many years.

Construction of Unit 3 began in 2006, and the latest Advanced BWR (ABWR), which offers further advancements in reliability and safety, was adopted. The reactor was scheduled to come online in March 2012. With a rated electrical output of 1,373 megawatts, if it had entered operation it would have been one of Japan's biggest nuclear reactors.

However, just before the fuel was to be loaded, the Great East Japan Earthquake and Fukushima Daiichi Nuclear Power Station accident occurred, and the plan was suspended. In May of that year, the government at the time decided to postpone the start of operation.

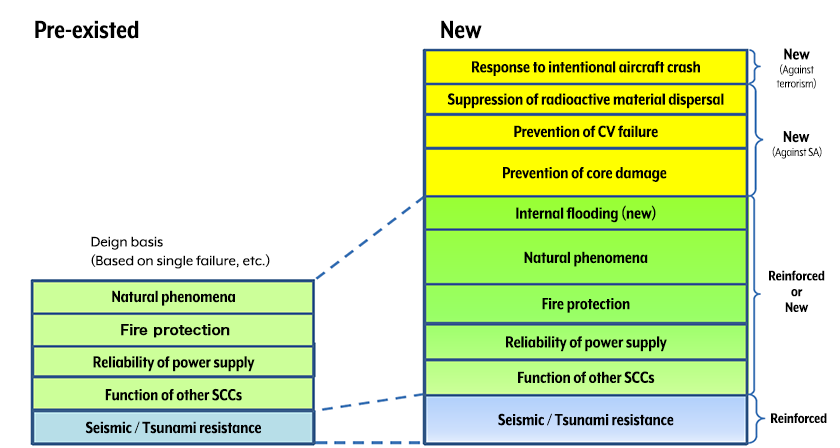

In the years since, learning from the lessons of the Fukushima accident, the construction of safety measures has been underway to comply with new regulatory requirements formulated in 2013 by Japan's Nuclear Regulatory Authority, the most stringent standards in the world.

Under the new regulatory requirements, new regulations were established for measures to deal with severe accidents, and power plants were also required to step up their efforts to deal with natural disasters. They were required to prepare for a wide range of risks from tornadoes to volcanic eruptions and forest fires in addition to earthquakes and tsunamis.

“I'm going to report on what kind of measures are in place,” explains Matsui as he heads towards the Unit 3 building.

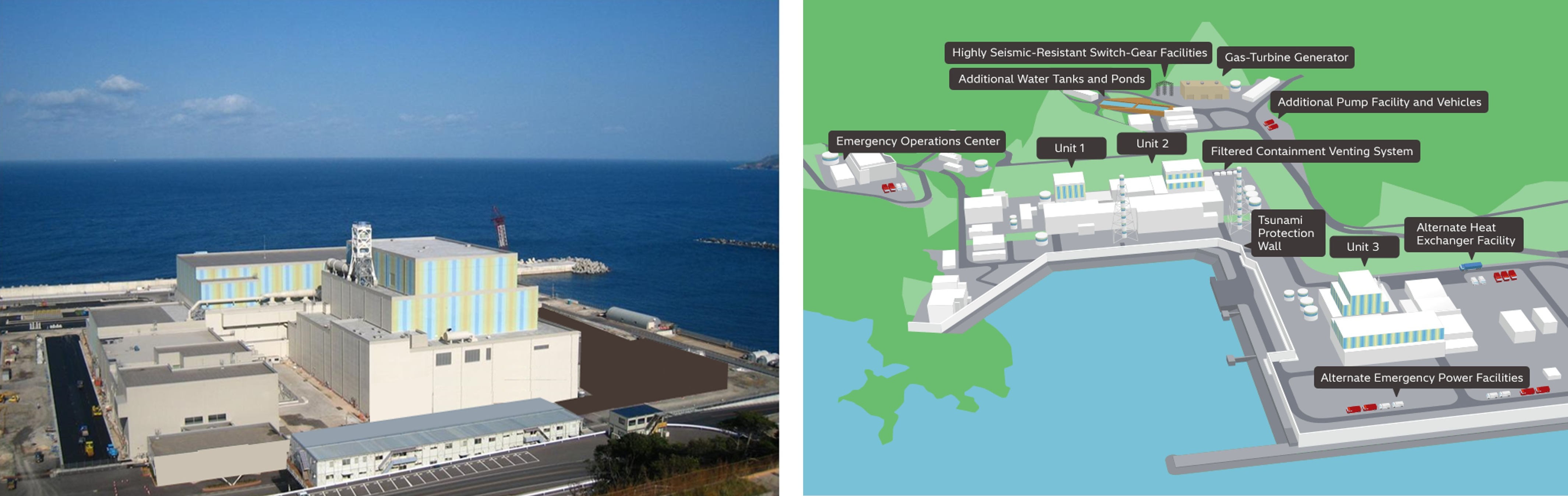

Exterior of Unit 3 of the Shimane Nuclear Power Station and layout of the entire power plant (Courtesy of the Chugoku Electric Power Co., Inc.)

Comparison of the pre-existed and the new regulatory requirements(Source: Nuclear Regulation Authority website)

Overall structure of Shimane Nuclear Power Station Unit 3

Matsui was first shown the Main Control Room, which is located inside the control building. This location is essentially the command center, and is responsible for the overall operation and monitoring of the power plant, including key equipment such as nuclear reactors, turbines and generators, as well as complicated systems.

This is where the improved main control panel is employed, designed to prevent human error by allowing switches to be operated while monitoring operational status on large display panels.

Next it was on to the gallery, an area located on the fifth floor of the reactor building that provides a view of the reactor operational floor. Located on the top floor of the reactor building, after completion this location will be used for fuel exchange work and so on, but for now it is being used as an observation room with informational panels and other items on display.

Descending to the third floor, the group proceeded to the upper drywell, which is positioned above the reactor containment vessel made from reinforced concrete, known as the Reinforced Concrete Containment Vessel, or RCCV. This space is designed to contain reactor coolant that would be released in the event of ruptured reactor coolant piping or a similar incident.

Descending further, Matsui expressed surprise at seeing the suppression chamber. Located below the reactor containment vessel, the suppression chamber holds a large amount of water. When an accident occurs, it is designed to pass steam through water to cool it and return it to a liquid state, preventing the pressure inside the reactor containment vessel from rising excessively. The large amount of water can also be used as reactor coolant in an emergency.

It is also designed so that when it is necessary to externally vent gases from inside the containment vessel, the gases are first passed through water to dissolve radioactive substances into it, reducing the radioactivity of the radioactive materials released outside.

“The suppression chamber itself has been around for a long time, and in a conventional BWR, the suppression chamber is a round cylinder forming a ring, making a donut shape. Here, it is positioned under the containment vessel, forming a pool that runs all the way around it, and its size is many times greater than I had imagined.

With a depth of 19 meters, when you look down on it from above, it makes you feel weak at the knees. This is a truly enormous safety system. As this is a location you can never access once the power plant is operational, it was a rare and valuable experience.”

Next, Matsui was shown the Hydraulic Control Unit (HCU) room, where he received an explanation. Using pistons, HCUs supply high-pressure water to control rod drives, the mechanisms responsible for inserting and withdrawing control rods. During an emergency shutdown of the reactor, known as a “scram,” they instantaneously force the control rods into the reactor with water pressure.

The Unit 3 HCU room employs the module-based construction method, where the entire room is assembled at a factory and then transported to the site. It is constructed by integrating the entire room as-is at the site.

“With the previous construction method, over 100 HCUs had to be mounted and connected to piping one at a time. As well as being time-consuming, since it involved working in tight spaces, it took a large toll on field workers.

If the HCUs are assembled in a factory where it is easier to work and the entire room is then installed as a single integrated unit, it not only significantly shortens the construction time but also increases safety and reduces workload, which helps prevent work errors. It's not just the equipment but the construction methods that have evolved,” remarked Matsui with excitement.

Next, the tour proceeded to the pedestal and lower drywell on the first basement level. The pedestal is a steel cylindrical shell structure filled with concrete and is a foundational structure whose main purpose is to support the reactor unit. The lower drywell is a space used to replace control rod drives and transport them in and out of the facility.

After covering the reactor building, the tour moved on to the turbine building. This is where the steam generated by the reactor is used to turn turbines and generate electricity. After steam has been used to drive the turbines, it is cooled and turned back into water in a condenser, and then circulated back to the reactor with water supply pumps. Matsui toured the operational floor where the operation and management of this process take place, and received explanations about the various equipment.

After touring the building, Matsui spoke with conviction. “Seeing an under-construction nuclear power plant up close, I was reminded of how robust they are. I could see that the safety measures have not only evolved, but are also being thoroughly implemented.”

“The reinforced concrete walls of the reactor containment vessel are two meters thick. That was previously known, and today I got to actually see that and confirm its toughness. However, no matter how strong the wall is, if the cooling functions of the reactor are lost and hydrogen continues to be generated, eventually the pressure will be too great and an explosion will occur. To prevent that from happening, when the pressure rises, gases from inside the reactor containment vessel are vented into the atmosphere, and by passing those gases through a filter when doing so, filtered containment venting system is properly installed to limit the radioactive materials released to the outside. I was able to verify that in addition to preventing accidents from occurring in the first place, there are measures in place to limit the impact should the unthinkable occur.”

The installation of filtered containment venting system is required under the new regulatory requirements, and installation has also taken place in Unit 2 of the Shimane Nuclear Power Station, which resumed operation in January 2025. Other site-wide measures to deal with accidents at the Shimane Nuclear Power Station include raising the tsunami protection wall to 15 meters above sea level, securing external and emergency power supplies, and the incorporation of measures to deal with tornadoes and volcanic ash into building designs.

After completing the facility visit, Matsui sat down for an interview with Hitachi's Site Manager Koichi Fujimura, who is responsible for Hitachi's construction activities related to Unit 3 of the Shimane Nuclear Power Station.

Fujimura is from Aomori Prefecture. When he first joined Hitachi, he was assigned to the Power Design Department, working on the design of turbine generators. When he later learned about plans to construct a nuclear fuel reprocessing plant in Rokkasho Village in his home prefecture of Aomori, he requested a transfer. After working on the design of equipment and devices for the reprocessing plant in the Nuclear Energy Development Department, he worked on construction management on-site. For a one-year period from April 2011, he worked on the construction and operation of contaminated water treatment systems at the Fukushima Daiichi Nuclear Power Station, and from 2019 has been involved with construction at the Shimane Nuclear Power Station.

“Here at the Shimane Nuclear Power Station, operations were suspended in 2012, and that lasted until Unit 2 finally resumed operation in January 2025. How did it feel at the time?” asked Matsui.

“As my main responsibility was construction work for Unit 3, I was only involved with Unit 2 in a support capacity, but it lifted the spirits of everyone, myself included, to achieve the first restart of a reactor that had been worked on by Hitachi, because everyone had passionately committed themselves to this work with the belief that they would ensure a safe restart, no matter what,” replied Fujimura.

Just before Unit 3 was scheduled to enter service, they were forced to suspend construction, and spent each day working to strengthen safety measures. Asked whether it was difficult to stay motivated over that period, Fujimura answered.

“Sure, we faced an ongoing situation of not knowing what the schedule for starting operation would be. However, our strong desire to contribute to the stable supply of electricity with nuclear energy sustained us. A major premise of operating a nuclear power plant is gaining the understanding of the local community, and not losing their trust. That can only be achieved by facing each task before you one at a time, without cutting corners.

Especially here, since it is the only nuclear power plant in Japan located in a prefectural capital, the source of our motivation was the strong awareness that quality and safety must be observed at all costs.”

When Matsui asked “perhaps Hitachi's corporate culture plays a part in maintaining that attitude,” Fujimura nodded. “I think so. The driving force of working hard to produce results, and the mindset of seeing things through to the end might not be visible on the surface, but they are deeply rooted qualities we have carried forward as a company.”

Koichi Fujimura, Hitachi Construction Site Manager, Shimane Nuclear Power Station Unit 3

To conclude his reporting, Matsui visited the Shimane Nuclear Visitor Center, the PR facility of the Shimane Nuclear Power Station. The facility, built on a high point overlooking the Sea of Japan, not only offers opportunities to learn about nuclear energy, but also conducts a range of activities designed to deepen engagement with children in the local community through various events.

“I get a sense for the commitment to coexisting and moving forward with the local community here,” says Matsui, speaking with admiration. “When I was visiting the power plant, I heard that figure for the output of Unit 3, 1,373 megawatts, is inspired by the number 1373, a nod to the phonetic rendering of “Izanami” in Izanami-no-Mikoto, a goddess in Japanese mythology. I do get a sense of “Izumo,” the land of these myths. Perhaps this also represents the plant's desire to be connected to the local community, even down to these small details.”

The Shimane Nuclear Visitor Center displays full-scale models of a section of the reactor pressure vessel, fuel pellets, and part of the reinforced concrete wall of the reactor containment vessel, allowing visitors to experience the scale and robustness of a nuclear power plant firsthand. “Since you can get a feeling for how huge and sturdy a nuclear power plant is and the sense of scale involved, I would recommend it to anyone who has the opportunity.”

Having spent a day visiting the Shimane Nuclear Power Station, Matsui summed up his impressions from the site and his interview with Fujimura with a single word: “integrity.” The sight of engineers sincerely and steadily working to make safety a reality gave him a sense of hope.

“Today I had the opportunity to see the people working on-site, and while I only exchanged a few words with them directly, they conveyed how good the atmosphere was. They were clearly communicating with one another and working with a sense of pride, and seeing that was truly impressive. I want everyone to know that it is people like them who are supporting Japan's energy and, by extension, the foundations of our society.”

Matsui was also impressed by the thorough implementation of safety measures.

“I was aware that the new regulatory requirements require measures against tornadoes, but I learned that not a single vehicle is parked around Unit 2, which is currently operating, to prevent vehicles from being swept up by a tornado and crashing into the building. I was impressed to see that thorough measures have been put in place, not only at the hardware level but also at the operational level.”

Unit 3 of the Shimane Nuclear Power Station is scheduled to enter service by fiscal 2030.

“I will be personally following with keen interest to see the pursuit of safety in the lead-up to, and following the start of operation.”

Yasumasa Matsui

Freelance Announcer and Journalist

Born in Inami, Nanto City, Toyama Prefecture. Graduated from Toyama Prefectural Takaoka High School. Graduated from the Department of Chemical Engineering, School of Engineering, Tokyo Institute of Technology (now Institute of Science Tokyo). In 1986, he joined TV Asahi as an announcer. He co-hosted Music Station with Tamori, served as a sportscaster on News Station, and worked as a news and information anchor on programs such as Station Eye, Wide Scramble, and Yajiuma Plus.

In 2008, he became the principal of TV Asahi's announcer school, Ask. During his two years in this role, he trained over 100 announcers who went on to work nationwide. In March 2011, following the 2011 Great East Japan Earthquake (and subsequent Fukushima Daiichi Nuclear Power Station accident), he transferred from the announcer department to the news department as a reporter covering the nuclear power plant accident. He later served as a reporter covering the Imperial Household Agency and weather-related disasters, and worked as a commentator. In 2023, after leaving TV Asahi, he established his own agency, OFFICE Yuzuki. He also serves as a plastic model history research advisor for Tamiya Inc., ambassador for Nanto City, Toyama Prefecture, and media advisor for sake company, DASSAI Inc.