Hitachi was founded in Hitachi City, Ibaraki Prefecture, where more than 10 major works and R&D facilities of the Hitachi Group are located, including the Hitachi Works, the Omika Works and the R&D Group's Ibaraki Site. Of these facilities, Yasumasa Matsui visits facilities that are related to the nuclear energy and energy fields in particular. We deliver a four-part series on the origin of Hitachi, current operations and R&D initiatives in the nuclear sector, human resources development for the future and coexistence with local communities.

The first installment features his visits to two museums. One is Nippon Mining Museum, which displays the history of Hitachi Mine (currently, JX Advanced Metals Corporation). This is where Hitachi, Ltd. was founded. The other museum is Hitachi Origin Park. There, he looks into the origin of the Hitachi Group and its history. Matsui explores how the spirit that Fusanosuke Kuhara passed on to Namihei Odaira, the founder of Hitachi, lead to the Hitachi's current stance toward the Social Innovation Business and energy technologies. Kuhara squarely addressed the mining pollution issue and aimed for coexistence between companies and local communities, in the late Meiji Period and the Taisho Period (from the early 1910s to the mid-1920s), and Odaira sought to develop original made-in technologies and led the development of manufacturing in Japan.

Hitachi, Ltd. was founded in Hitachi City, Ibaraki Prefecture. When you drive northwest from the city center, you quickly reach the end of the urban area and enter the mountains. After driving for around 20 minutes through green trees on the ascending road along the Miyata River, the Nippon Mining Museum appears in the valley. It displays the history of the Hitachi Mine to visitors.

The Nippon Mining Museum is a corporate museum run by JX Advanced Metals Corporation. It was built at the former site of Hitachi Mine where the company was founded. In 1905, entrepreneur Fusanosuke Kuhara established the Hitachi Mine. Using modern technologies, the mine quickly developed into one of the four greatest copper mines, comparable to the Ashio, Besshi and Kosaka copper mines. It aided the development of Japanese industry through copper production in the 76 years up to its closure in 1981.

After the mine closed, the Nippon Mining Museum opened in 1986 in commemoration of the 80th anniversary of the foundation of the mine. Utilizing mine structures that still stand today, the museum contains various exhibits to show the history of the Hitachi Mine and the JX Advanced Metals Group and Kuhara's entrepreneurial spirit.

The Main Exhibition Hall, made of concrete stands against a backdrop of trees. Its straight lines leave the impression that it is massive and sophisticated.

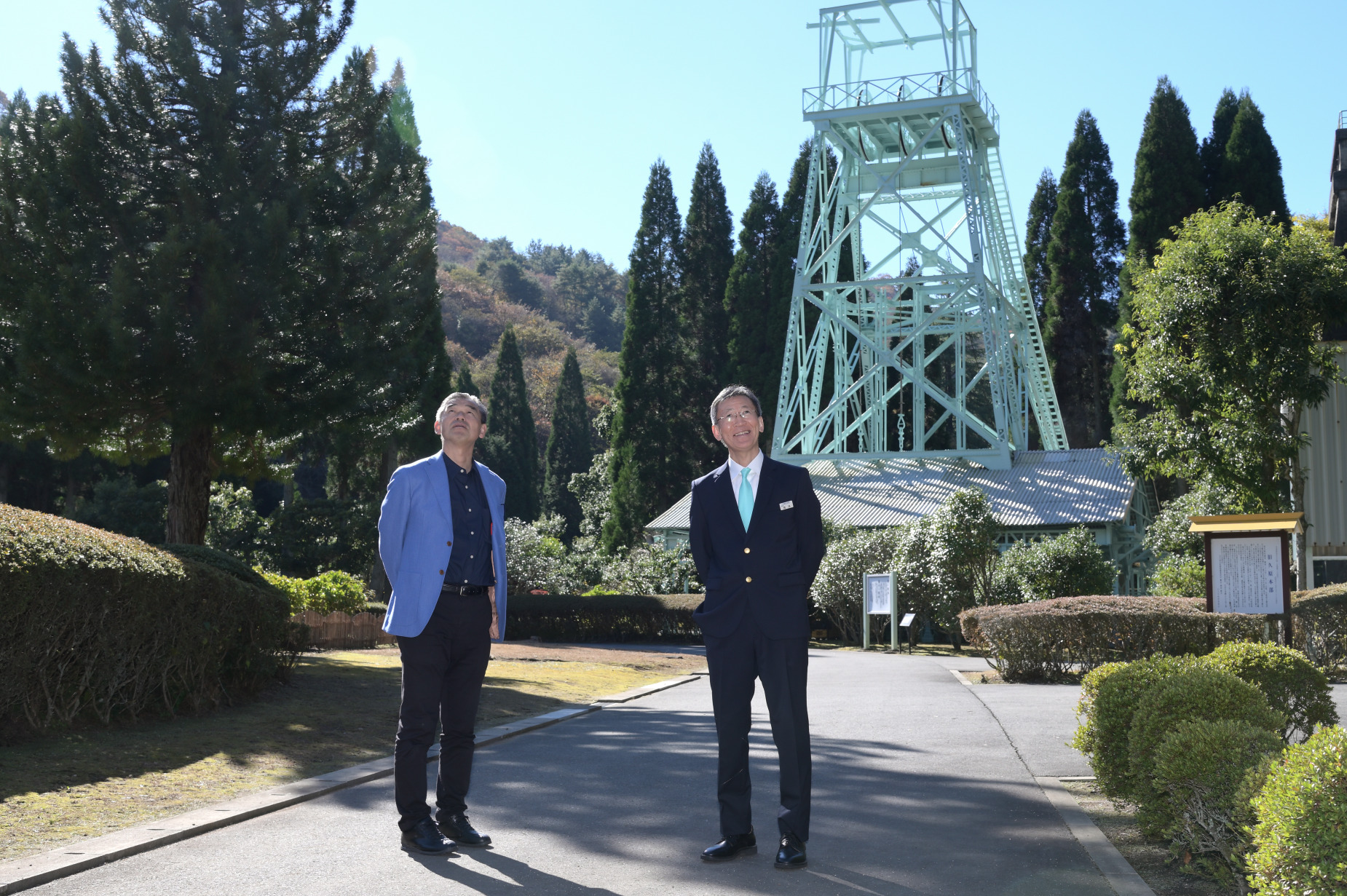

Under a clear blue sky in late fall, Matsui went to the Main Exhibition Hall as soon as he arrived at the museum. At the museum's entrance, Jyunichi Shinohara, the general manager of the museum, greeted him with a smile and said, “Welcome to Nippon Mining Museum.” Guided by Mr. Shinohara, Matsui viewed a video presentation about the Hitachi Mine. It was produced in commemoration of the 100th anniversary of the foundation of the mine. He then viewed the displays in the Main Exhibition Hall, the Mining Exhibition Hall and former Kuhara's Head Office and the abandoned mine shafts, etc. The Mining Exhibition Hall is a wooden building that was built as an air compressor room in 1944. The building is now used as it was for exhibition purposes. The former Kuhara's Head Office is where Kuhara lived in the early days of the operation of the mine. It is now an Ibaraki Prefectural Government designated cultural property.

Standing in front of the No. 1 Shaft Headframe with Mr. Shinohara. The shaft is a vertically excavated tunnel that is a roadway for moving miners and ore.

A hoist was used to move a metal cage up and down like an elevator to transport people and goods. The excavation of the No. 1 Main Shaft began in February 1906, just after the Hitachi Mine was opened. It was the main artery of the mine for the 75 years up to its closure in 1981.

Mt. Kamine, a low mountain at the south end of the Abukuma Mountains, is where the Hitachi Mine was opened. In the far past, gold had been mined in this area. In and after the Edo Period, copper was mined, leading to the mine being called the Akazawa Copper Mine. Due to mining pollution and other factors, mine operations had stagnated. Fusanosuke Kuhara was 36 years old, a young businessman at the time, when he identified the potential of the mine, purchased it in 1905 and named it the Hitachi Mine, after the name of the local village. He utilized his experience in the redevelopment of the Kosaka Copper Mine in Kosaka Town, Akita Prefecture, to modernize the Hitachi Mine and turn around the business.

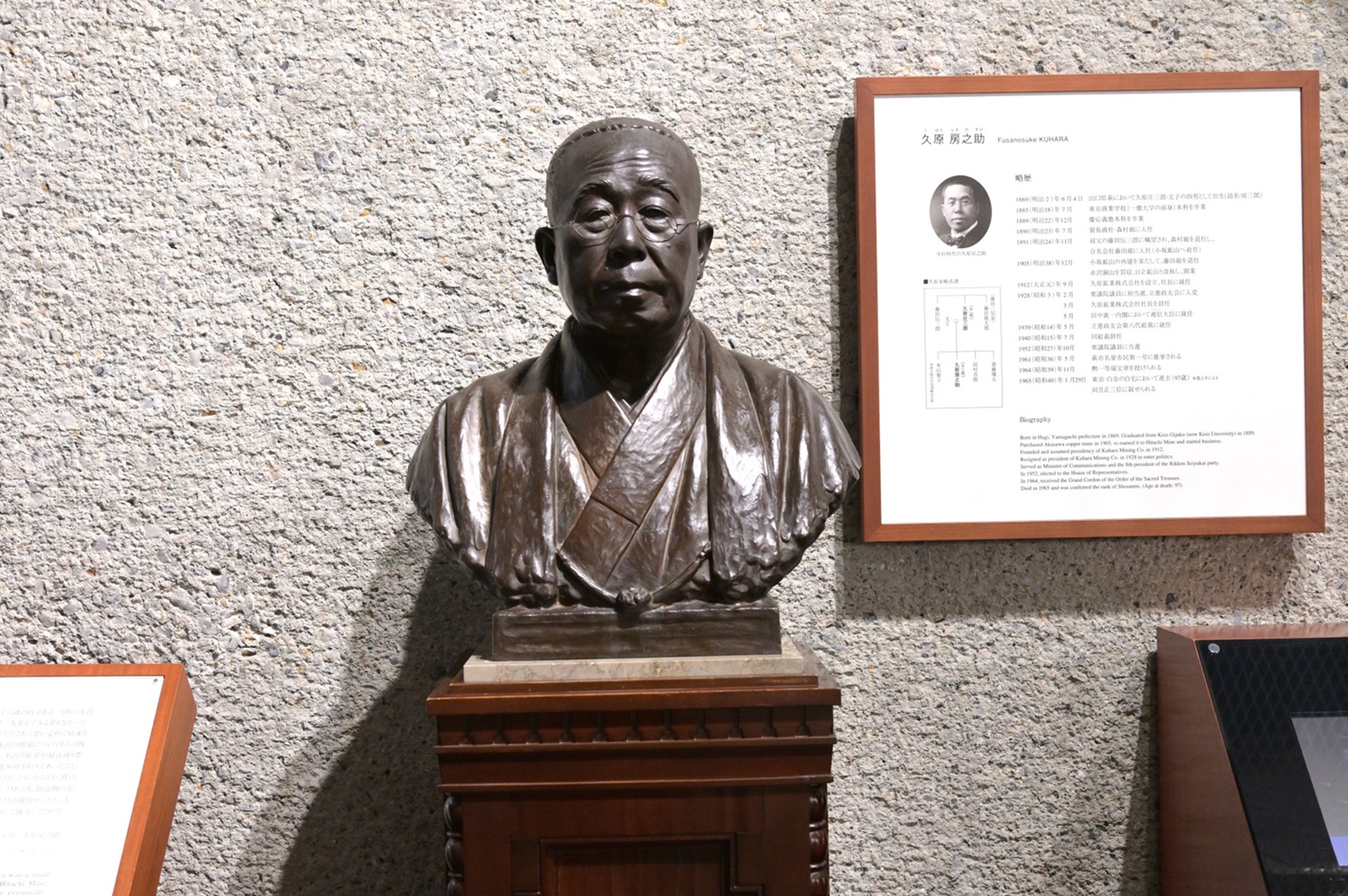

A bust of Fusanosuke Kuhara is on display at the museum. Matsui said, “When he was young, in his thirties, he purchased a mine and rebuilt it as a business.

I am amazed at his energy and spirit, although the situation in the Meiji Period might have helped him. I respect him.”

To modernize the mine, it was necessary to develop an organization and introduce machinery. To do this, Kuhara thought that electricity would be an essential source of energy. In 1906, he asked Namihei Odaira, with whom he worked at the Kosaka Copper Mine, to build a power plant. After gaining access to electricity, Kuhara carried out operational reforms such as the switch from conventional manual excavation to using rock drills to mine and the introduction of pumps to draw groundwater. This paved the way toward deeper mining. As a result, the volume of ore mined increased quickly, and Hitachi Mine grew significantly.

At this time, Odaira was appointed as the head of the work section. He gave instructions regarding the construction of a copper smelter, ore transport facilities and electric railways. At the same time, he also repaired foreign-made electric machines used at the mine. As he spent his workdays repairing equipment in a small log house, he gradually increased his knowledge and skills. In 1910, he successfully built a five-horsepower induction motor together with his subordinate engineers. In the same year, a factory for manufacturing electric products using all-Japanese technologies was built in a corner of the mine. This is how Hitachi, Ltd. was born. At that time, Odaira was 36 years old.

Matsui was very interested in one of the museum's displays, a perspective model of ore deposits and shafts. Mr. Shinohara explained that the deepest tunnels were 950 meters below the museum, which is at an elevation of 350 meters above sea level. The approximate total length of the tunnels is 700 kilometers. The main shaft equipped with an elevator to convey miners, ore and materials descends to a depth of 600 meters. For comparison, the Tokyo Skytree is 634 meters tall. Matsui said, “Excavating 700 kilometers of tunnels in a place that is definitely not visible from ground level and in an environment that is as challenging as outer space is beyond my imagination even today, not even considering that this was done 100 years ago. It shows that the cutting equipment and measuring technologies had reached the highest level in the world at that time, despite the limiting conditions. The 3D perspective model enabled me to see this at a glance. It stunned me—in a good way.”

The hoist for the No. 1 Main Shaft has a huge motor that turns the drum to wind and unwind the wire, moving the cage up and down.

It is preserved and displayed as it was when it was in service.

Many of the rock drills used in the mine are on display in the Mining Exhibition Hall.

About two years after the start of mine operations, damage to the agricultural products grown in the area began to be identified. It was believed this damage was due to the sulfur dioxide gas contained in the smoke from the copper smelter. Yataro Kado, who later became the head of the mine, was the head of the mine's general affairs section. He was assigned to handle the damage caused by the smoke. His basic policy was to proactively compensate people for the damage that he was able to confirm was a result of the smoke to fulfill the ethical responsibilities of the mine.

The mine sincerely compensated local inhabitants, but the damage increased in line with the increase in the smoke emitted as the mining business grew. In addition to agricultural products, the forests were also being damaged. Local residents' discontent with the mine increased. The Hitachi Mine worked harder to control the damage caused by the smoke. Their experiments achieved only limited effects. In this situation, Kuhara came up with the idea that releasing smoke at the highest possible position may reduce the damage. He spent a large amount of money to construct a 155.7-meter-tall chimney. At the time, it was the tallest chimney in the world. The Hitachi Mine introduced reinforced concrete construction technology that was cutting-edge at the time and 36,000 workers or more were assigned to erect the big chimney. The project was completed in just nine months. The chimney began to be used in 1915. It reduced the damage from the smoke considerably.

The Hitachi Mine also established an observation network of weather observation stations installed in a 10-kilometer radius around the mine. It also introduced measures such as restrictions on smelter operations to reduce the amount of smoke when weather conditions might cause the smoke to fall to the ground.

In addition to these pollution-mitigation measures, the Hitachi Mine set up an agricultural experiment station to research agricultural products and trees that are resistant to smoke. The mine learned that Cerasus speciosa, commonly known as Oshima cherry, was resistant to smoke. The station started to grow young Oshima cherry trees it ordered from Izu-Oshima island.

The Hitachi Mine patiently grew seedlings from seeds, gradually increasing the number of seedlings that it planted in the mountains. Ultimately, the Hitachi Mine planted more than five million seedlings. It distributed seeds for smoke-resistant agricultural products and fertilizers to farmers. It also provided approximately 5,134,000 Japanese black pine, Japanese cedar and Oshima cherry seedlings for free to neighboring towns and villages.

These activities were implemented over approximately 20 years, and a total of more than 10 million seedlings were planted or provided to neighboring communities to make the mountains green again. In addition, those responsible for planting the trees also grew a number of Yoshino cherry seedlings by grafting them to Oshima cherry trees. The Hitachi Mine planted around 2,000 Yoshino cherry trees throughout the city of Hitachi. Due to the persistent efforts of the people who came before us, Hitachi City is now known as a popular place for cherry blossom viewing.

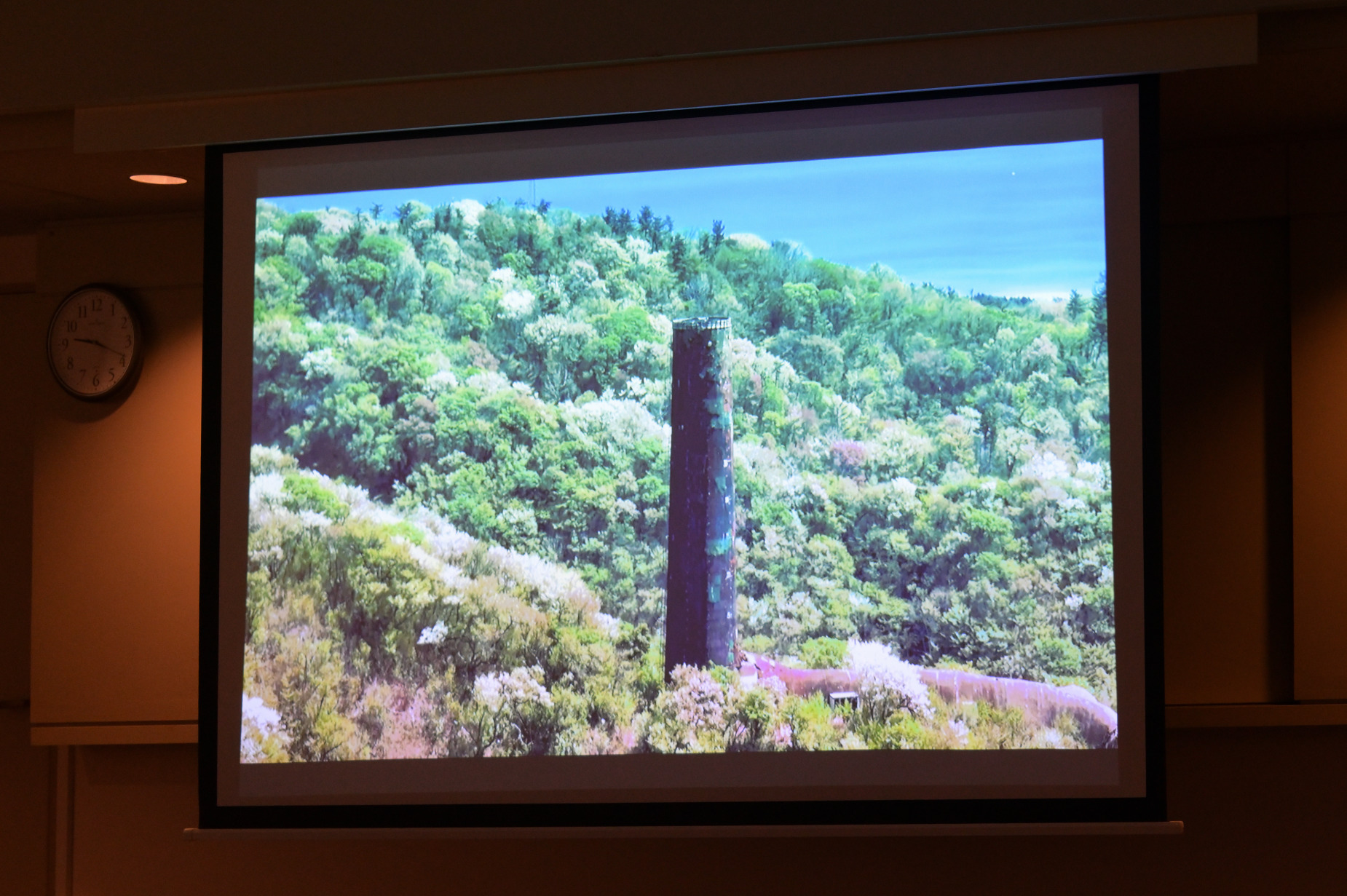

The big chimney was left standing after the mine closed in 1981, but the upper part of the chimney collapsed due to age-related deterioration in 1993. It is now one-third of its original height, but it is still a symbol to the local residents. The story of the collaboration between the Hitachi Mine and local residents regarding the smoke damage was described in the novel Aru Machi no Takai Entotsu (A Town and A Tall Chimney) by Jiro Nitta, Showa literary master, and a movie based on this novel was produced in 2019.

The chimney today is one third as tall as it used to be. Matsui said, “The aspirations of the company and local residents to coexist and mutually prosper are engraved in this big chimney. I have heard that when it collapsed, it fell towards the mountain so that it did not damage anything when it fell. Mr. Shinohara explained that some argue that it was designed to fall towards the mountain in the event of a collapse. When I think of the spirit of the engineers in that period, I feel that this scenario is not impossible.”

Deeply moved by the tour, Matsui said, “Honestly, many things about the history of the Hitachi Mine were new to me. They were very impressive.”

He continued, “Kuhara put overcoming the smoke damage issue at the heart of the mine's management issues and risked the fortunes of the company to address it. Their planting and providing at least ten million seedlings were impressive to me. The mine pollution at the Ashio Copper Mine before the incident at the Hitachi Mine and the different examples of pollution in the period of Japan's rapid economic growth are well known, but I feel that society should be more aware that this sensible stance of firmly addressing pollution had already been taken in those days. I also learned why groves of cherry trees bloom beautifully in Hitachi in the spring. I happened to find a DVD of the Aru Machi no Takai Entotsu movie, and I bought it on impulse.”

Kuhara believed that for a mining business to be successful, employees had to be able to work with peace of mind. He worked hard on employee welfare. For instance, he constructed not only accommodations for them but also a school, a hospital, a store that sold food and daily items at low prices, recreational facilities and an electric railway exclusively for the mine that employees could ride for free.

“The mine itself was a town. Kuhara also contributed to the development of this community as a whole through business and the planting of cherry trees. The Hitachi Mine had a visionary corporate stance analogous to the stances of companies today regarding the management of environmental, social and governance (ESG) issues—and Namihei Odaira preserved this spirit.”

After leaving Nippon Mining Museum, Matsui visited Hitachi Origin Park, which is a short distance from Omika Station on the JR Joban Line. Hitachi Origin Park opened in November 2021. It includes the Omika Club and the Omika Golf Club, which are Hitachi Group welfare facilities, and other newly built facilities on the premises of the park, such as the Odaira Memorial Museum and the Sogyo Goya (founding factory). Matsui looked at the Omika Golf Club course before touring the Odaira Memorial Museum.

The Hitachi Golf Club, the forerunner of the Omika Golf Club, was established in 1936 for the welfare of Hitachi's employees and the entertainment of overseas visitors. The club has experienced twists and turns, including downsizing and the conversion of land into farmland, but it continues to exist today.

It is a Hitachi Group welfare facility, but it is also open to the public. Local residents enjoy the club, including the restaurant on the second floor of the clubhouse.

Matsui visited the Odaira Memorial Museum. He thought about the Hitachi Group's 115 years of history, during which it continuously worked to achieve its mission, “Contribute to society through the development of superior, original technology and products,” and Namihei Odaira, the founder of the Hitachi Group, who established the founding spirit.

The Odaira Memorial Museum contains exhibits and panel displays about the developments that led up to Namihei Odaira founding Hitachi, Ltd. and the products Hitachi has made. It provides visitors with a vivid opportunity to learn about Hitachi's endeavors and the history of its development of technology juxtaposed with the history of industry around the world. Zone 1 showcases materials related to Odaira's origin. A surround screen shows a video of his path from being a student to the foundation of Hitachi.

After watching the video, Matsui said that he was able to empathize with Hitachi's predecessors, partly because of his visit to the Nippon Mining Museum before he came to Hitachi Origin Park.

“Odaira graduated from the department of electrical engineering at the Tokyo Imperial University and later was the chief electrical engineer at the Kosaka Copper Mine. After that, he was the chief power transmission engineer at Tokyo Electric Light Co., Ltd., which is currently known as Tokyo Electric Power Company Holdings, Incorporated. This position was enviable and it had a high salary, but he gave it up without regret and devoted himself to the mine. This was because he was in alignment with Kuhara's aspirations and he wanted to make electric machinery himself due to the concerns about Japan's dependency on foreign technologies since he was a student. I have come to understand the strength of his will,” Matsui said.

Matsui looks at Hitachi's first product, the five-horsepower induction motor. “Odaira reportedly wrote, 'Japanese industry will not develop if it is content simply copying foreign products' in his notebook. I feel that this product represents the original form of Japanese manufacturing—in which technologies are first learned through the imitation of imported items so that better products can be produced,” Matsui said.

The next exhibition traces Hitachi, Ltd.'s path from its achievements as a Hitachi Mine repair workshop through the foundation of the business in 1910 and its breakthroughs in the domestic production of electric machinery to the advancement of its business.

The electric fan was Hitachi's first exported product

In the 1920s, Hitachi expanded its domestic production of electric and infrastructure equipment, including power generation and substation equipment and transformers. In the wake of the Great Kanto Earthquake in 1923, Hitachi supplied electric machinery preferentially to the Keihin district, which had been hugely damaged by the disaster. Without being swayed by immediate profit, it worked to facilitate reconstruction for the sake of society. The ultimate result of these efforts was that the public gained confidence in the quality of Hitachi products and its corporate attitudes, which led to an increase in its market share in Japan and abroad. This was the start of Hitachi's development into one of Japan's leading general electric appliance manufacturers.

In the post-war period of rapid economic growth, Hitachi quickly expanded its electronics business and began fully operating a made-in-Japan computer business. It became one of Japan's first companies to work on addressing social issues such as pollution and the need to conserve energy.

Later, the Japanese bubble economy burst, and this was followed by the 2008 financial crisis. To survive in these difficult times, Hitachi selected the businesses it would focus on, concentrating its resources in its Social Innovation Business and becoming a solution business. While maintaining the Hitachi Founding Spirit, it aims to overcome the diverse issues that society is facing, establish a sustainable society and help improve people's wellbeing through Collaborative Creation with its customers around the world.

“During Hitachi's long history, its products and businesses have changed, but it has retained its mission, 'Contribute to society through the development of superior, original technology and products,' and it has continued to address social issues. The exhibition clearly communicates that this is Hitachi's corporate stance,” said Matsui.

Hitachi's advanced energy system initiatives with the goal of achieving carbon neutrality by 2050 are presented in the museum. Panels and models demonstrate new solutions and technologies for the entire energy value chain.

In this section of the museum, Hitachi's history of taking on challenges is traced visually. The display evoked a sense of nostalgia for Matsui.

He exclaimed, “This is the Pompa television, right? We had one at home!”

Matsui moved on to the Sogyo Goya. It is a reconstruction of the repair workshop in the work section of the Hitachi Mine, the origin of Hitachi. Four five-horsepower induction motors produced when Hitachi was founded are preserved. One of them is on display at the Sogyo Goya, where visitors can see it in operation. Inside this simple wooden hut, there is a large wooden table and other items to reproduce what the workshop was like at the time Hitachi was founded, enabling visitors to feel close to Odaira and the other engineers who worked with him.

Wandering inside the hut, Matsui thought about that era.

“I have heard that the Hitachi Founding Spirit consists of Harmony, Sincerity, Pioneering Spirit. I imagine that young technological pioneers energetically discussed issues, taking on challenges in this tiny house in a corner of the mine at that time.”

Matsui pressed the switch to start the motor, which suddenly made a loud noise, causing a surprised Matsui to say, “Oh!”

The Hitachi Hattatsushi (History of Hitachi's Development) documentary film produced during World War II is shown inside the Sogyo Goya.

From the Nippon Mining Museum to Hitachi Origin Park, Matsui saw the origin of Hitachi and its history since its foundation. Looking back at his experience, he said, “I feel strongly that the two facilities do not merely preserve the past. They are a part of our heritage that brightens the future.” He added that Kuhara had passed the baton of social innovation to Odaira.

“It may be a coincidence that the origins of both the JX Advanced Metals Group and the Hitachi Group are at the Hitachi Mine. I suppose that their development was natural. In my view, Kuhara invited Odaira to Hitachi Mine because he recognized Odaira's capabilities, and Kuhara's personality could be one of the reasons that Odaira went to work for the Hitachi Mine. Odaira shared Kuhara's aspirations to support the foundation of Japan’s industrial base and to coexist and prosper together with the local community, including employees. He took over and further expanded this spirit. They were both capable and proud people. This spirit has been continuously passed down to their successors. I believe that is something that shapes what the Hitachi Group is today.”

At the time Matsui was visiting Hitachi Origin Park, a large number of elementary school children were also there, looking at and listening closely to explanations of the exhibitions.

He said, “I feel that the local community that Kuhara aimed to realize through the mining business is identical to Hitachi's current vision of a harmonized society, which is a society in which economic growth is in harmony with the global environment and with human wellbeing. I hope with all my heart that children will not only learn about the past, but also come to understand that the ideals and principles of their predecessors, which originated at the Hitachi Mine and have been passed down through generations since Odaira, are a link to the future, and that they will carry them forward.”

Yasumasa Matsui

Freelance Announcer and Journalist

Born in Inami, Nanto City, Toyama Prefecture. Graduated from Toyama Prefectural Takaoka High School. Graduated from the Department of Chemical Engineering, School of Engineering, Tokyo Institute of Technology (now Institute of Science Tokyo). In 1986, he joined TV Asahi as an announcer. He co-hosted Music Station with Tamori, served as a sportscaster on News Station, and worked as a news and information anchor on programs such as Station Eye, Wide Scramble, and Yajiuma Plus.

In 2008, he became the principal of TV Asahi's announcer school, Ask. During his two years in this role, he trained over 100 announcers who went on to work nationwide. In March 2011, following the 2011 Great East Japan Earthquake (and subsequent Fukushima Daiichi Nuclear Power Station accident), he transferred from the announcer department to the news department as a reporter covering the nuclear power plant accident. He later served as a reporter covering the Imperial Household Agency and weather-related disasters, and worked as a commentator. In 2023, after leaving TV Asahi, he established his own agency, OFFICE Yuzuki. He also serves as a plastic model history research advisor for Tamiya Inc., ambassador for Nanto City, Toyama Prefecture, and media advisor for sake company, DASSAI Inc.