How can we digitize the "resourceful tact" of craftsmen? For planning operations at manufacturing sites, highly accurate technologies that satisfy both efficiency and quality, as craftsmen do, are further required.

To date, it has been extremely difficult to express the implicit knowledge of experts, such as know-how and hunches, into numerical formulas and automatically create satisfactory plans. Hitachi has made it possible with its new constraint programming technology, which integrates mathematical optimization and big data analysis. Innovations that take advantage of human capabilities to the fullest have started.

KOBAYASHI Yuichi

Senior Researcher

ZHENG jian

Researcher

(Publication: December 19, 2017)

KOBAYASHIThat's right. We are conducting research on what is called constraint programming technology. It automatically creates optimal plans for manufacturing sites and other areas using "mathematical optimization," which finds the most appropriate solutions while satisfying constraint conditions.

This technology has been best utilized in preparing railway service planning diagrams (timetables, etc.). They must be prepared in the face of various constraint conditions. For example, how many trains can be stopped at station platforms and at which stations express trains can overtake local trains must be considered. Preparing accurate service planning diagrams in a limited period of time is quite difficult, especially for such super-dense lines as those running in the suburbs of Tokyo. In this regard, the technology makes it possible to instantly prepare optimal service planning diagrams that satisfy many constraint conditions by adopting mathematical optimization.

ZHENGWe considered widely applying this technology in other areas, including the production plans for the iron and steel industry. For several years, we were engaged in developing a new technology by extending the conventional one, and came out with the Machine Learning Constraint Programming, or MLCP. It is a new constraint programming technology integrated with machine learning, which is an analysis technology for big data.

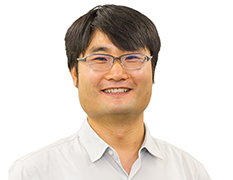

Figure 1: Integration of mathematical optimization and machine learning

ZHENGThe research for the iron and steel area was triggered by a customer, who consulted us on whether it was possible to create a mechanism that incorporates the resourceful tact of craftsmen and produces the desired outputs by utilizing IT technologies. The customer's question was based on the fact that, in the iron and steel area, many operations depend on expert planners, and a large part of knowledge is held only by the experts. Such knowledge includes hunches, know-how, and what is called "implicit knowledge," which cannot be expressed in language. In this regard, the conventional technology was aimed at extracting the implicit knowledge held by the experts and reflecting it in production plans.

KOBAYASHILet me add a bit. We had already started integrating mathematical optimization and machine learning in the railway area as we mentioned before. At railway operating companies, when service planning diagrams must be changed suddenly, experienced service planning diagram programmers do so promptly based on the information on where trains are running. We tried to adopt mathematical optimization for this, but we found that it didn't go well by changing the service planning diagrams simply in accordance with the constraint conditions. When they prepare service planning diagrams, experienced service planning diagram programmers consider even such matters as by what time certain trains must arrive at certain stations, as there are cleaning staff waiting. The service planning diagrams are full of such expert know-how. It was difficult for us to reflect such know-how in the plans. This made us start our endeavors to digitize the implicit knowledge of experts, and we later horizontally extended the application to the iron and steel area.

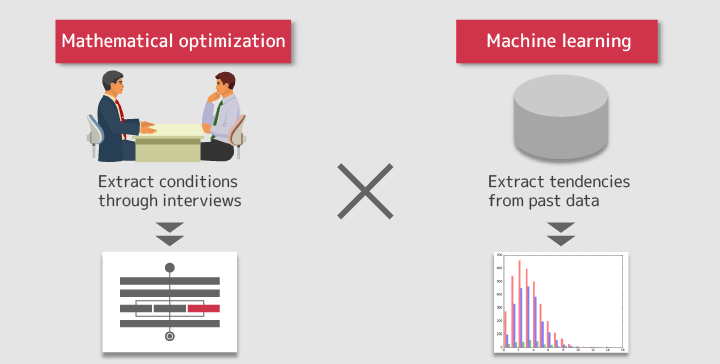

ZHENGIn the conventional system, constraint conditions were clearly documented through interviews with customers, and plans were prepared to conform to the conditions. However, this was insufficient for us, as it does not allow us to reflect the implicit knowledge of experts in the plans. In contrast, the MLCP extracts implicit rules of experts from the historical data of plans, on top of the clearly documented constraint conditions, and achieves overall optimization for planning.

As for the approach the MLCP takes in solving issues, it employs machine learning to generate several planning patterns from the historical data of plans previously made by the experts. From the patterns, MLCP extracts the tendencies, or feature quantities, which shows the plans people tend to prepare for certain cases. The extracted tendencies are added to the clearly documented constraint conditions, which are obtained through the conventional methods, so that satisfactory plans are created.

Figure 2: Overview of new constraint programming technology

KOBAYASHISuppose there are given constraint conditions, such as the number of employees working at the plant and their working hours being from 8 a.m. to 5 p.m. The conventional system cannot prepare production plans that achieve production capacity beyond these conditions. However, the experts prepare plans flexibly according to the circumstances. For example, when express orders are received, they intentionally disobey the constraint conditions and call for a bit of overtime work for the week to increase the production volume. The new system makes it possible to learn the "resourceful tact" of humans from the historical data of the past through machine learning, and prepare plans that intentionally disobey the constraint conditions in order to meet express orders.

KOBAYASHIIt was at a time when there was a surge in big data analysis, and computer games of shogi and go gave us hints for this idea. In fact, as a typical man with a scientific background, I tend to value logic in determining things. Initially, I was blindly confident that we should be able to make it if we grasp all the conditions through interviews with the customers, ask the customers about what is lacking, and write everything based on the if-then rule (in conditional expressions). However, of course, there was a limit to what we could do in this manner. We could not fully write human resourceful tact or ambiguity in accordance with the if-then rule. Moreover, we need to deal with multi-product production nowadays. If products or facilities change, the rules also change and the system must be modified. That was another issue we had to tackle.

For the computer shogi games, the programs were originally made with standard moves in established tactics written by the if-then rule. However, machine learning was later adopted in preparing the programs. Once the programs learned the records of games by professionals through machine learning, they were able to beat human players. This gave us a hint, and we considered using machine learning in preparing plans.

ZHENGFor a while after applying this technology, we were not able to produce results that were satisfactory for the customer. So we received feedback from the customer by communicating with them, and worked to enhance accuracy by improving incorrect sections. We repeated this process over and over.

KOBAYASHIEssentially, machine learning is suitable for photo identification and language translation. So there have been few cases in which machine learning was applied in creating something. On the other hand, mathematical optimization is used for preparing plans (solutions). Thus, combining them was extremely difficult. It is even difficult to explain how difficult it was.

For example, suppose you have a plan that conforms to the constraint conditions and another that slightly disobeys them. Unless you establish a good balance as to which one is prioritized, you cannot make a good plan that would be envisioned by experts. When extracting the features through machine learning, it is important and difficult to determine how well the plan's features on the experts' minds can be extracted.

ZHENGFirst, you need to obtain knowledge of operations in each area, be it railways or iron and steel. Still, from our own perspectives, we cannot tell whether the extracted results are correct or not. As we communicated with the customers, we gradually came to understand what they mind or care about.

ZHENGWhen results of our prototypes are obtained, I make it a practice to honestly tell the customers what I believe should be improved or solved. By doing so, I could share my views and awareness with the customers. Then, I proceeded with my assignments while receiving feedback from them. When I worked on their feedback, I tried to produce results as quickly as possible.

KOBAYASHII keep in mind to speak from the customers' perspective as much as possible. Earlier, when I had few opportunities to meet the customers and was not accustomed to doing so, I talked only about technologies. But the customers did not understand what I was talking about at all, and we often could not communicate well with each other. I reflect on this, and remind myself to be careful.

In addition, each industry has special terms or jargon that the customers take for granted. I try to remember them correctly and talk with the customers using their words.

ZHENGThe customer made a presentation on the new technology at a seminar, and we attended. On this occasion, the customer said that it was an "off-the-wall solution," which made an impression on us. As far as I understand, it may mean achieving what could not be achieved before. I think the customer felt that our technology would be helpful in addressing the issues they had not been able to solve. Honestly, I was very pleased as the customer used such an expression in front of many people, and I believe the first step in our task is to satisfy the customer.

ZHENGAt present, we aim to enable the system to prepare plans as good as what experts make. Looking ahead, I hope we can develop technologies that can surpass the abilities of the experts. Our target is to allow the system to suggest good plans to experts when they prepare plans.

KOBAYASHII believe that digitizing the know-how of experts can contribute to taking advantage of human capabilities to the fullest. Essentially, preparing plans is often conducted by capable people. The new constraint programming technology should help such people to use their time for more creative tasks. It would be great if that indirectly contributes to enhancing productivity and earnings.

ZHENGI want to become a top-level researcher globally in the area of optimization by continuously conducting research on the subject.

KOBAYASHII would say my dream is to create artificial intelligence which I can proudly tell my children about. Once they asked me about what I produce, and I replied that I create artificial intelligence. Nearly two years have passed since I started working on the technology with the customer coaching me, and my children told me, "Daddy, your artificial intelligence is not quick to learn." Well, they were exactly right (laugh). Machine learning technology is making magnificent progress, and its practical applications are advancing. However, technologies to create something new by utilizing what is learned are still in the research stage. Preparing plans is one such technology. I hope I will be able to realize artificial intelligence that allows computers to "create" something on their own by learning from humans.