- ASEAN Manufacturing

- Urgent Transformation

- Industry 4.0 Challenges

- Hitachi's Lumada

- Smart Manufacturing

Discover how Hitachi Smart Manufacturing drives innovation across industries

5 key components of Industry 4.0

INTERNET OF THINGS

Sensors allow equipments to share data to a central repository

BIG DATA ANALYTICS

Uncover patterns and correlations in your data to raise productivity

CLOUD-BASED TECHNOLOGIES

Cost-effective infrastructure, scalable on-demand

ARTIFICIAL INTELLIGENCE

Apply machine learning to your datasets for enhanced solutions

ADVANCED MANUFACTURING

Innovative technologies to improve your product design and production

How critical is manufacturing to ASEAN?

Manufacturing contributes

of ASEAN’s GDP in 2018

billions

Home to the sixth largest global economy in 2019 at around US$3 trillion, ASEAN is projected to grow at an average of 4.9% per annum for the next decade. As a core growth driver, manufacturing contributes about US$670 billion or 21% to the region's GDP in 2018.

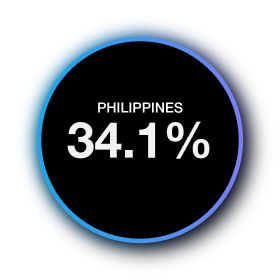

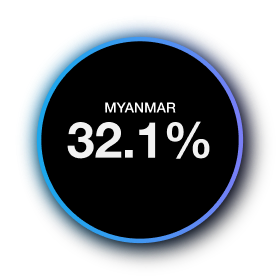

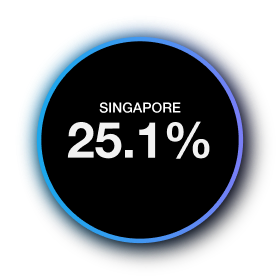

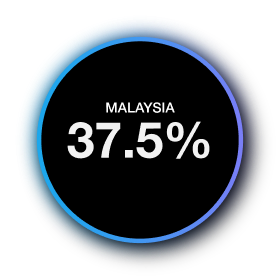

Size of ASEAN's manufacturing sector

compared to total GDP of the country in 2018

In spite of its size, ASEAN's manufacturing sector only ranks fourth in the world, behind China, United States and Germany. In terms of average productivity, all ASEAN member states, with the exception of Singapore, scored significantly lower than United States and Germany.

Comparing ASEAN's manufacturing productivity

manufacturing productivity is defined as value added per employee, measured in thousands of US$, as of 2017

USA

Germany

China

ASEAN

Room to grow in terms productivity

Gains in manufacturing productivity

From 2008 to 2017

USA

Germany

China

ASEAN

Potential gains in productivity with Industry 4.0

Industry 4.0 promises to change that by escalating the region's manufacturing value. However, the current pace of adoption lag behind China, which has invested heavily in automation and robots in the past 10 years. This move has enabled Chinese productivity to grow by 84%, compared with 38% on average for ASEAN.

THEN, COVID-19 CAME AND CHANGED EVERYTHING

Urgent need for TRANSFORMATION

COVID-19 drove an urgent need to modernise operations.

Telling tales of manufacturers' reliance on manual processes and operations, coupled with the lack of visibility designed into their supply chains have surfaced. Both hinder manufacturers' ability to respond dynamically during times of uncertain demand. Modernising these capabilities will be essential for manufacturers to recover from the pandemic quickly.

To put it simply, COVID-19 is spearheading this sector towards urgent transformation.

Challenges of racing up the industry 4.0 ladder

With a renewed urgency to commit to Industry 4.0, ASEAN manufacturers are now rushing headlong into technological upgrades. 39% of manufacturers have implemented a nerve-centre, or control-tower, approach to increase end-to-end supply-chain transparency.

Around a quarter are fast tracking automation programs to stem worker shortages arising from COVID-19.

While the escalated pace of change is impressive, the race to becoming smart factories of tomorrow is marred with three challenges: data silos, lack of skilled managers and cybersecurity threats.

Building smart factories with LUMADA

With a firm belief in the ASEAN's manufacturing future, Hitachi has taken the first step to set up Lumada Centre, in Thailand in 2018. Serving as a digital services hub, Lumada aims to equip Southeast Asian companies with IoT capabilities, big data analytics as they move up the Industry 4.0 ladder.

Lumada is an IoT platform that allows you and Hitachi to co-create customized digital solutions to suit your business needs. It offers access to Hitachi's advanced technologies through the analysis of your data, which is then used to add value to your business operations through the implementation of big data analytics and artificial intelligence.

Having worked closely with manufacturers, Hitachi understands that talking about smart factories and data analytics can sound intimidating at first. However, many manufacturers become more receptive after learning how new technologies help to lower costs, raise productivity and ultimately, increase their profits.

Besides enabling smart factories, Hitachi also aims to elevate the logistics sector by incorporating smart technologies across the entire logistics and delivery network.

In 2019, Hitachi rolled out a sharing service for commercial vehicles in Thailand.

With this service, business owners can benefit from the efficient use of out-of-service vehicles across their fleet and perform joint deliveries for cargoes with close-proximity end destinations.

Not one to stand still, Hitachi is evolving Lumada's capabilities further through research partnerships.

Through research partnerships with tech companies, Hitachi is able to offer solutions to manufacturers in three areas.

Increase Manufacturing Productivity

Analyse data collected from manufacturing sites to optimise factory operations.

Optimise Logistics with Data Analytics

Analyse traffic congestion, storage and delivery locations to enable smart routing to save miles and deliver faster.

Predictive Maintenance and Remote Assist

Deploy predictive maintenance, real-time remote assistance and remote training for frontline workers.

Interested to learn more about how Hitachi Smart Manufacturing can help you?

Click on one of our case studies to find out more now.

Pivot Power - How GM and Hitachi moved from autos to medical masks in 6 days

Merging JUKI production facilities with Hitachi's operation know-how to bring advances to MONOZUKURI workplaces

Factories are trending towards Remote Work amid COVID-19: Expectations of Smart Factories of the future

Delivering Smiles to our daily lives - The frozen foods industry is evolving with digital technology

Click here to download reference for this infographic.

Date of Release: 18 February 2021