24 hours at the edge of Innovation

Batteries are a fundamental part of achieving a circular economy, helping to make renewable energy sources available consistently. Hitachi is engaged in a wide range of activities to create new, powerful, sustainable batteries.

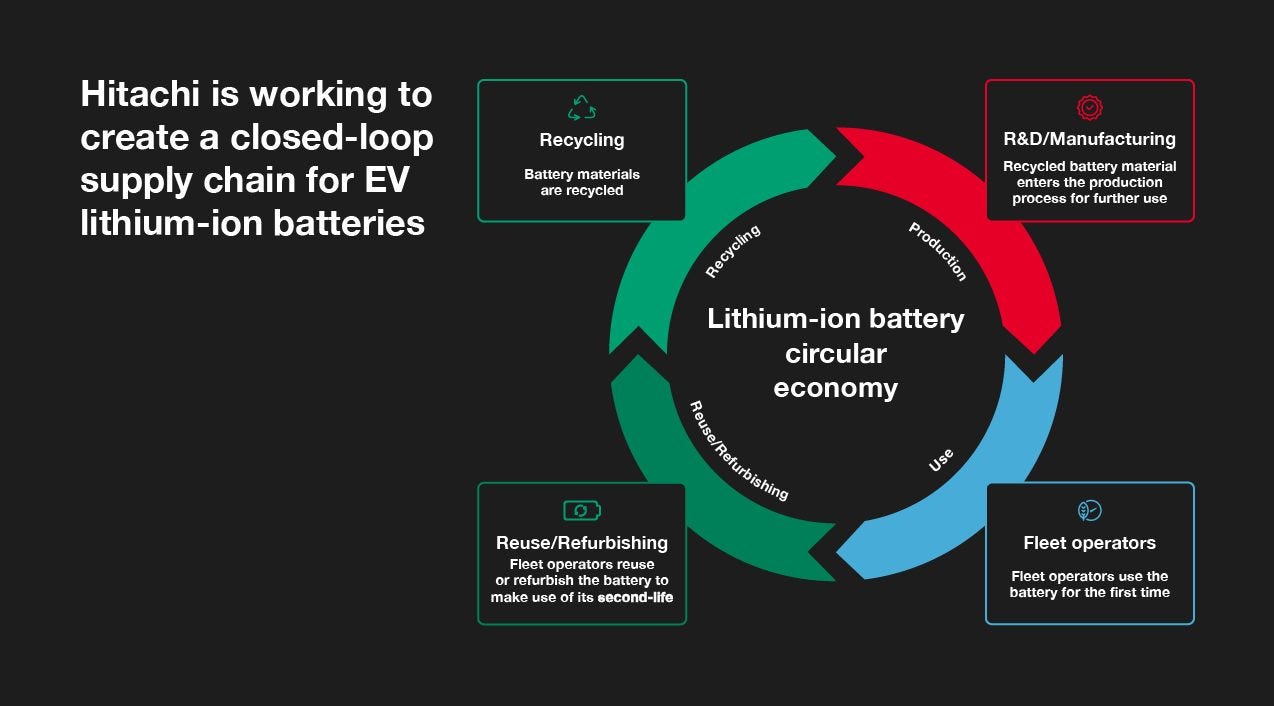

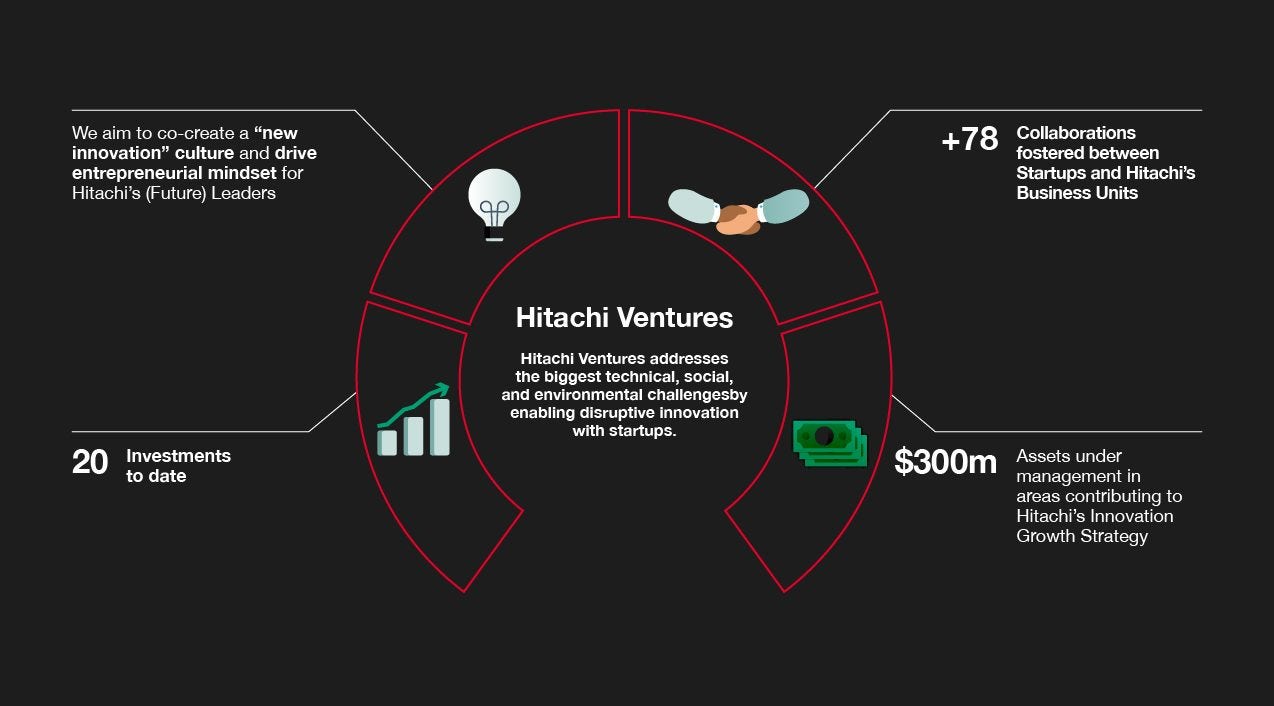

From Hitachi High-Tech Europe’s work to identify the high-quality materials in batteries that can be kept in circulation, to Hitachi Ventures-backed Ascend Element’s creation of a closed loop supply chain that makes recycled materials available to create high performance new batteries, we’re revolutionizing the lithium-ion industry. Our film looks at the endeavour to reduce waste for customers and support the circular economy with recycled batteries. As part of the Earthshot Prize Alliance, we’re backing ideas by innovators in climate change across the world: We visit ROAM in Kenya, where our experience is helping accelerate the Earthshot Prize finalist in their mission to electrify transport in Africa.

3 years

Until there’s a battery shortage. The demand for more high-performance batteries could lead to a shortage by 2025, according to the IEA.

2Bn batteries needed

The IEA’s Net Zero by 2050 roadmap says the world will need 2 billion battery electric, plug-in hybrid, and fuel-cell electric light-duty vehicles on the road by that date to hit net zero.

Articles

A ROAM engineer charging one of their electric vehicles inside the Nairobi factory.

Johannes Eschenauer works at the Hitachi High-Tech facility in Germany where they create and use battery health diagnostic tools and equipment.

Chris Saul, the Chief Strategy & Innovation Officer at Hitachi Europe, is working with ROAM as a mentor to help Kenya transition to electrification.

One of ROAM’s engineers performing battery diagnostics on one of their electric motorbikes.

An Ascend Elements operator transporting recycled battery materials in the Boston facility.

A deeper dive into the featured projects