Predictive-diagnosis algorithm

This solution employs a predictive-diagnosis algorithm based on Hitachi’s proprietary AI analysis model.

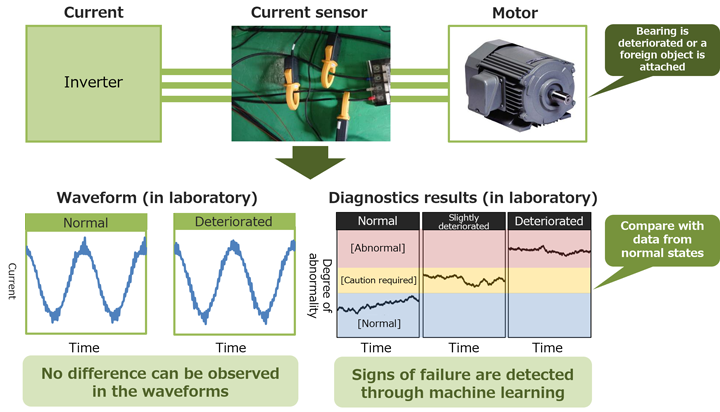

If the motor bearing deteriorates or if a foreign object enters the device, the load on the motor changes, and then the motor current behavior changes. The change in the behavior is so subtle that no difference can be found just by looking at the current waveform.

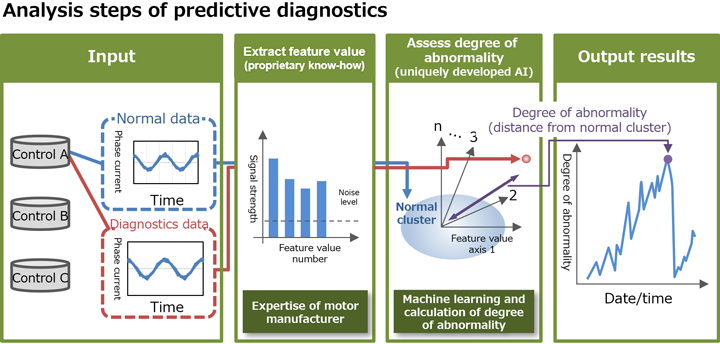

The predictive-diagnosis algorithm extracts and analyzes signals containing deterioration information about the motors to be diagnosed. First, this algorithm uses AI to learn the signals from new motors or repaired motors as normal data. Then, the algorithm applies machine learning to the learned data and the signals containing deterioration information about the motors running at the site, so that signs of failure will be detected.

Based on the motor-related expertise that Hitachi has cultivated over many years, the predictive-diagnosis algorithm identifies deterioration information that will be used for diagnosis. Hitachi has combined its domain knowledge in plant control and analytics technologies, and thereby developed technologies to detect signs of deterioration. For many years, Hitachi has been recognized for its domain expertise in plant control and analytics technologies.

Our predictive-diagnosis algorithm identifies various control patterns, associates them with the data on currents required for analysis, extract signals containing deterioration information as feature values, and performs quantification through machine learning.