The predictive-diagnosis solution using motor currents is applicable to cases such as the following:

Detection of abnormalities in conveyer-belt motors

Problems

- If any of the numerous conveyer-belt motors fails, the equipment will stop. Production will be adversely affected, and huge losses will occur. The manufacturer might lose the trust of customers.

- The manufacturer must avoid equipment stoppages and must do whatever it takes to maintain the equipment to prevent sudden equipment stoppages. As such, the manufacturer spends a huge amount on maintenance costs.

- A manufacturer might have hundreds or thousands of conveyer-belt motors. As such, the manufacturer must spend a huge amount on maintenance costs.

- The environments at sites are often harsh and can pose hazards to worker health.

Solution

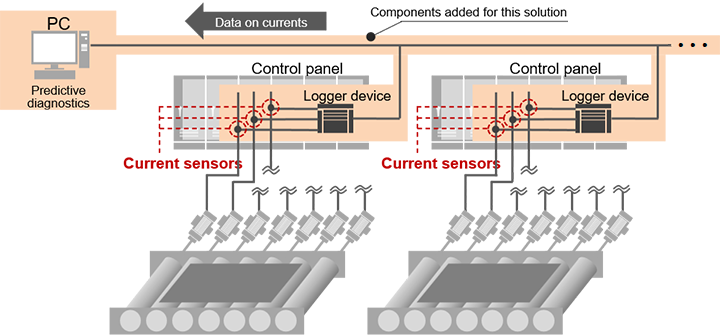

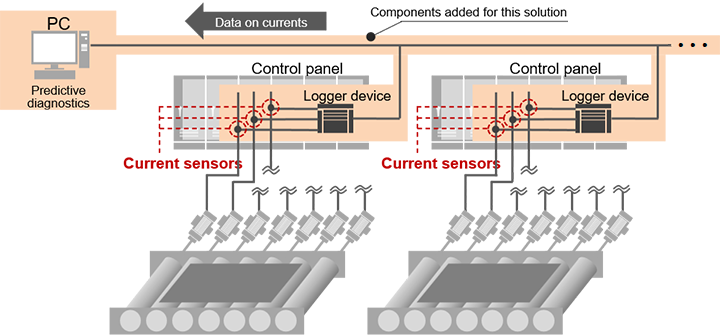

This solution diagnoses the state of the bearings in conveyer-belt motors to help customers perform maintenance operations. Current sensors and logger devices are installed in the control panels running the motors. They are used to collect the current data required for diagnosis and input that collected current data to the AI-based predictive-diagnosis algorithm. In this way, this solution makes it easy to see whether motors have deteriorated, which helps customers implement their maintenance plans. This solution will help prevent sudden failures and thereby prevent damage to business.

Example of a system configuration