Can we create a new system of manufacturing by utilizing autonomous mobility?

While the needs of consumers have become diverse, unique new products are being created by utilizing the 3D printer and other new production methods, as well as new funding schemes such as cloud funding. The starting point of manufacturing will shift from big companies which mass-produces products systematically to consumers having diverse needs. However, the conventional production system is limited in its capacity for such new products in order to satisfy huge demand. How can we ensure the steady distribution of such products for consumers?

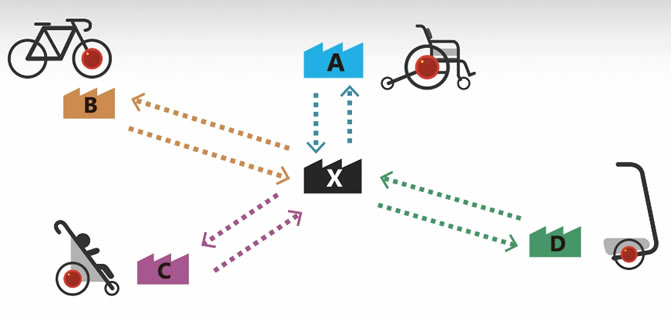

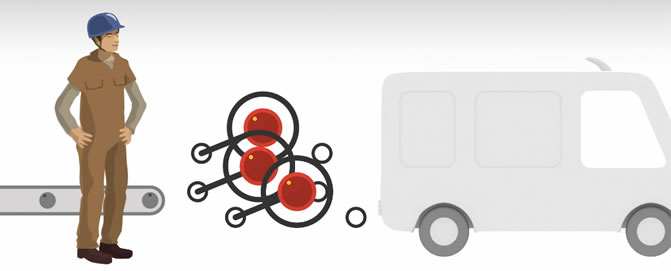

Here we propose a production system that forms a network to connect small-scale producers. Through the network, the producers can share facilities and technologies when necessary. We also propose a distribution system utilizing autonomous mobility that accurately and very frequently deliver goods from factory to factory.

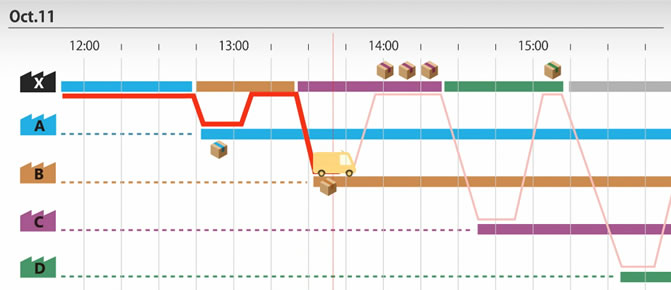

While the combination of producers changes in various ways, factories are connected seamlessly for the right items to be delivered at the right time. Small factories can thus quickly respond to diverse needs and ever-changing demand.

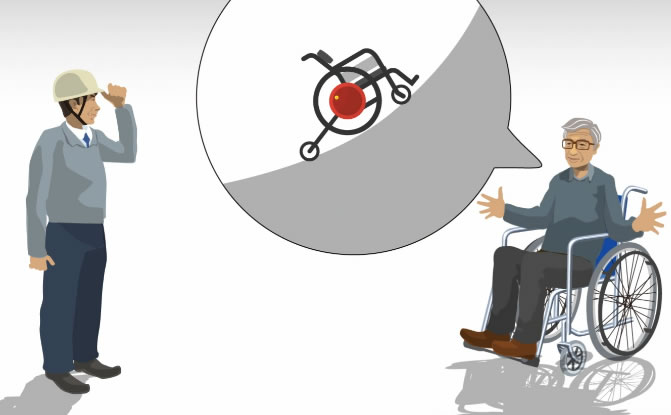

Here is an example of the customized production of a wheelchair. Devices need more diverse customization according to personal physical characteristics and the purpose of use. In order to add new functions and ensure maintenance, the need for such IoT technologies as sensors will increase. By encouraging the participation of producers possessing IoT and other new technologies in the network, more products that meet diverse needs will be produced.

When factories share production methods, processes and progress, goods will be delivered between factories at an optimal timing, thus alleviating the concerns of producers about distribution. And when small factories can minimize their inventory of parts to the level seen in the system adopted by big factories, the factories can participate in the network of new production even without having a big space for inventory.

This is a result of a research for Japan METI’s R&D and PoC of smart mobility system: a study of autonomous driving and its social values and use scenarios. (2016)